A kind of amorphous nanocrystalline composite magnetic powder core and preparation method thereof

An amorphous nanocrystalline and magnetic powder core technology, applied in the field of magnetic powder cores, can solve the problems of poor soft magnetic properties and mechanical properties of magnetic powder cores, damaged magnetic cores, and difficulty in meeting technical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

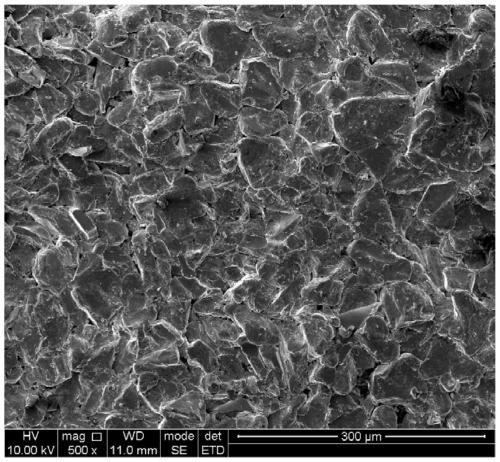

Image

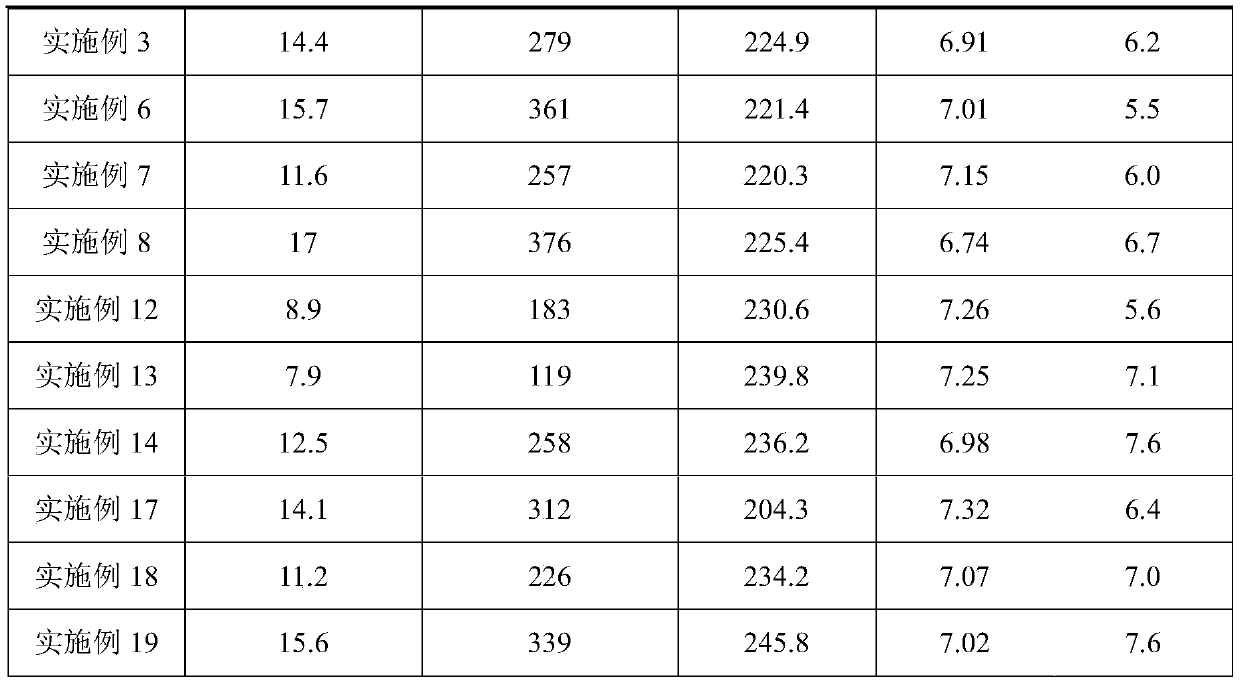

Examples

Embodiment 1~3

[0072] (11) Heat treatment of iron-based amorphous nanocrystalline magnetic powder

[0073] Will Fe 73.5 Si 13.5 B 9 Nb 3 Cu Fe-based amorphous and nanocrystalline magnetic powder was heat-treated in vacuum at 350°C for 1.5h, and the vacuum degree was 10 -1 Above Pa level.

[0074] (12) Preparation of nanoscale glass powder

[0075] Mix ethyl orthosilicate, ethanol, nitric acid and acetic acid in a molar ratio of 1:7:0.02:0.05, and stir vigorously at room temperature for about 0.5h until ethyl orthosilicate is completely prehydrolyzed to form the first mixture containing prehydrolyzed products liquid; the LiOH·H 2 O dissolved in LiOH·H 2 Obtain the first solution in the nitric acid of the amount of O twice substance; Ca(OH) 2 Soluble in Ca(OH) 2 nitric acid twice as much as the substance, to obtain a second solution; the H 3 BO 3 Soluble in H 3 BO 3 The deionized water of twice the amount of substance, obtains the 3rd solution; Will (Al(NO 3 ) 3 )·9H 2 O dissol...

Embodiment 4

[0083] (11) Heat treatment of iron-based amorphous nanocrystalline magnetic powder

[0084] Will Fe 73.5 Si 13.5 B 9 Nb 3 Cu Fe-based amorphous and nanocrystalline magnetic powder was heat-treated in vacuum at 400 °C for 1 h, and the vacuum degree was 10 -1 Above Pa level.

[0085] (12) Preparation of nanoscale glass powder

[0086] Mix ethyl orthosilicate, ethanol, nitric acid and acetic acid in a molar ratio of 1:7:0.02:0.05, and stir vigorously at room temperature for about 0.5h until ethyl orthosilicate is completely prehydrolyzed to form the first mixture containing prehydrolyzed products liquid; the LiOH·H 2 O dissolved in LiOH·H 2 Obtain the first solution in the nitric acid of the amount of O twice substance; Ca(OH) 2 Soluble in Ca(OH) 2 nitric acid twice as much as the substance, to obtain a second solution; the H 3 BO 3 Soluble in H 3 BO 3 The deionized water of twice the amount of substance, obtains the 3rd solution; Will (Al(NO 3 ) 3 )·9H 2 O dissol...

Embodiment 5

[0092] (11) Heat treatment of iron-based amorphous nanocrystalline magnetic powder

[0093] Will Fe 73.5 Si 13.5 B 9 Nb 3 Cu Fe-based amorphous and nanocrystalline magnetic powder was heat-treated in vacuum at 300°C for 1.5h, and the vacuum degree was 10 -1 Above Pa level.

[0094] (12) Preparation of nanoscale glass powder

[0095] Mix ethyl orthosilicate, ethanol, nitric acid and acetic acid in a molar ratio of 1:7:0.02:0.05, and stir vigorously at room temperature for about 0.5h until ethyl orthosilicate is completely prehydrolyzed to form the first mixture containing prehydrolyzed products liquid; the LiOH·H 2 O dissolved in LiOH·H 2 Obtain the first solution in the nitric acid of the amount of O twice substance; Ca(OH) 2 Soluble in Ca(OH) 2 nitric acid twice as much as the substance, to obtain a second solution; the H 3 BO 3 Soluble in H 3 BO 3 The deionized water of twice the amount of substance, obtains the 3rd solution; Will (Al(NO 3 ) 3 )·9H 2 O dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com