High performance environment-friendly capacitor dielectric and preparation method thereof

A capacitor and high-performance technology, applied in the field of capacitors, can solve the problem of low efficiency and achieve the effects of high production efficiency, improved energy storage efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method steps of the high-performance environment-friendly capacitor dielectric of the present embodiment are as follows:

[0037] Step 1: Preparation of Bi 0.83 SM 0.17 Fe 0.95 sc 0.05 o 3 (BSFSO) powder.

[0038] In this example, the total amount of the obtained BSFSO powder is 0.08mol, and the raw materials for the preparation of the BSFSO powder are shown in Table 1:

[0039] Table 1 Preparation raw materials of BSFSO powder

[0040] Drug Name

molecular weight

Drug purity

Experimental ratio

stoichiometric number

Weighing quality

465.96

0.9999

1

0.83

15.4714g

348.7

0.9999

1

0.17

2.3714g

159.69

0.999

1

0.95

6.0742g

137.91

0.999

1

0.05

0.2760g

[0041] Specific steps are as follows:

[0042] 1) Take each raw material according to the weighing quality in Table 1; ...

Embodiment 2

[0057] The preparation method of the high-performance environment-friendly capacitor dielectric of this embodiment is basically the same as that of Embodiment 1, the difference lies in the following two points:

[0058] ① Step 3 and step 4) During the hot pressing sintering process, through the cooperation of two experimenters, the sintering temperature was first raised to three different temperatures of 860°C, 840°C, and 820°C, and then kept for 5 minutes, and then obtained after cooling down. Three BSFSO ceramic samples prepared at different sintering temperatures.

[0059] ② Step 2 of Step 4) When plating the top electrode, the diameter of the hole on the mask used is 1mm.

Embodiment 3

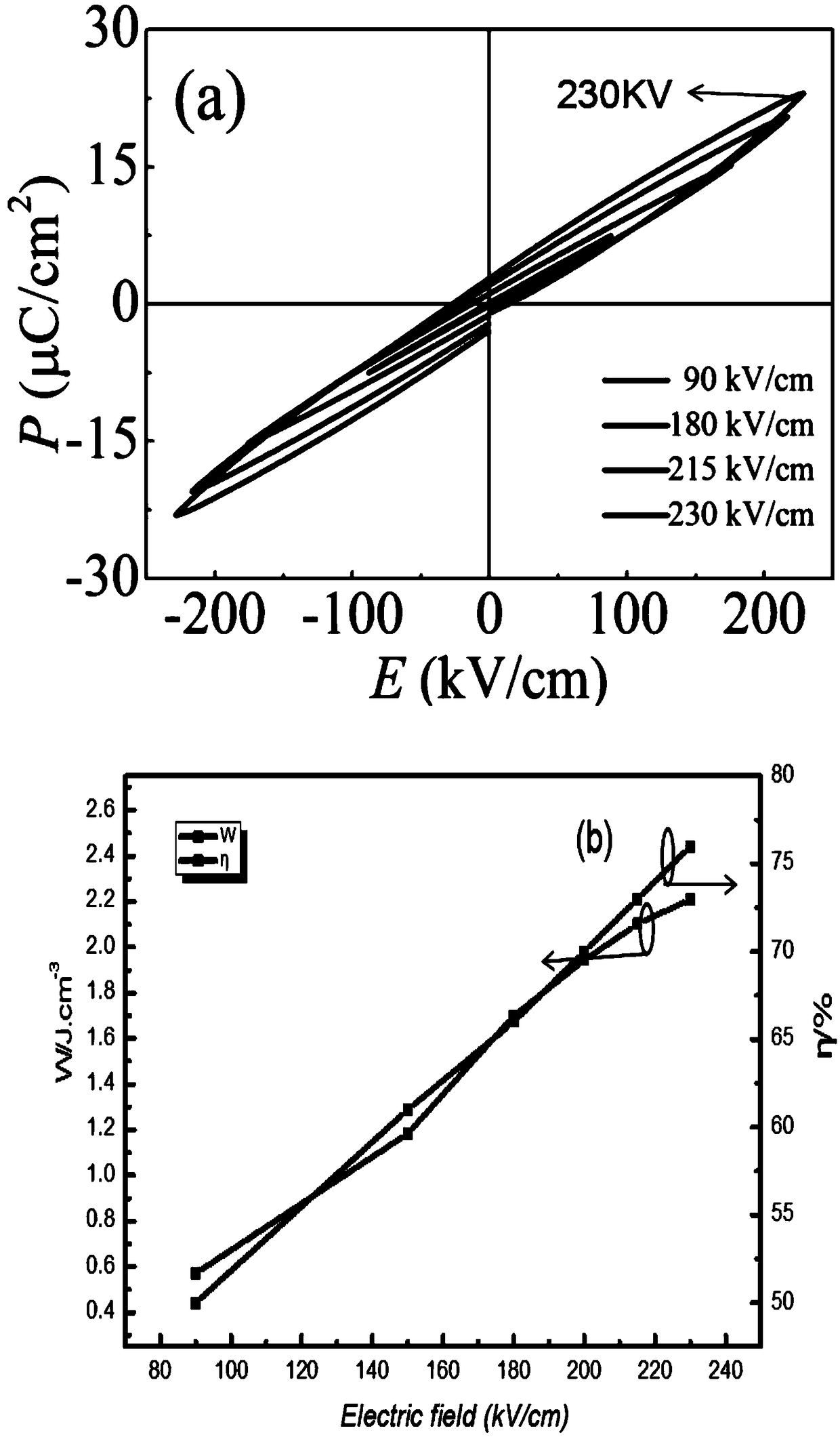

[0061] The high-performance environment-friendly capacitor dielectric that embodiment 1 and embodiment 2 make, i.e. the performance of BSFSO ceramics (samarium scandium co-doped BFO ceramics) is tested and characterized:

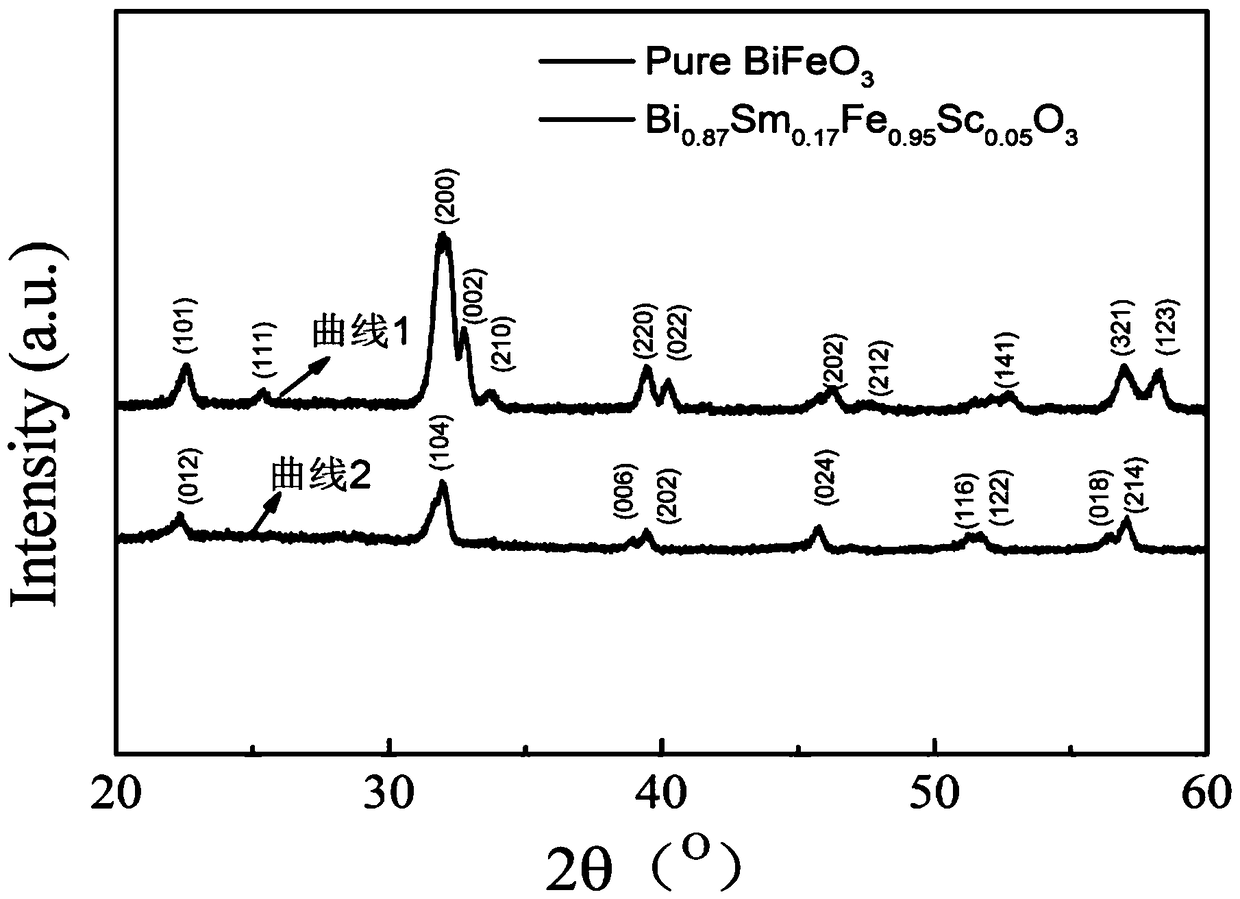

[0062] (1) XRD diffraction test

[0063] see figure 1 , which is the XRD diffraction diagram of the BSFSO ceramic sample and the pure BFO ceramic sample, the curve 1 in the figure is the XRD diffraction diagram of the BSFSO ceramic, and the curve 2 is the XRD diffraction diagram of the pure BFO ceramic. This test result is obtained by X-ray diffractometer (X'Pert PRO, PANalytical) to the BSFSO ceramics test that embodiment 1 makes. From figure 1 It can be seen from the figure that BSFSO ceramics can form independent phases without other impurity phases.

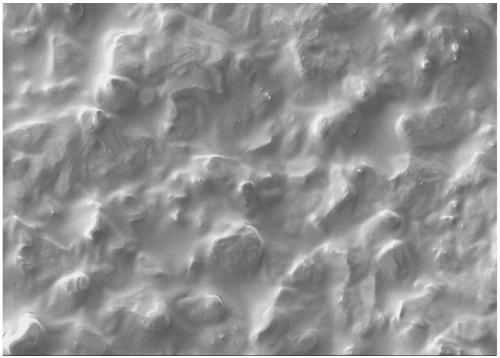

[0064] (2) SEM section characterization

[0065] see figure 2 , which is the SEM cross-sectional characterization diagram and partial enlarged diagram of the BSFSO ceramic sample. The test results are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com