Surface-modified bone meal and preparation method thereof

A surface modification and bone powder technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of bone cell adhesion and inductive reduction, and achieve the effects of good mechanical properties, tight adhesion, and normal growth shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

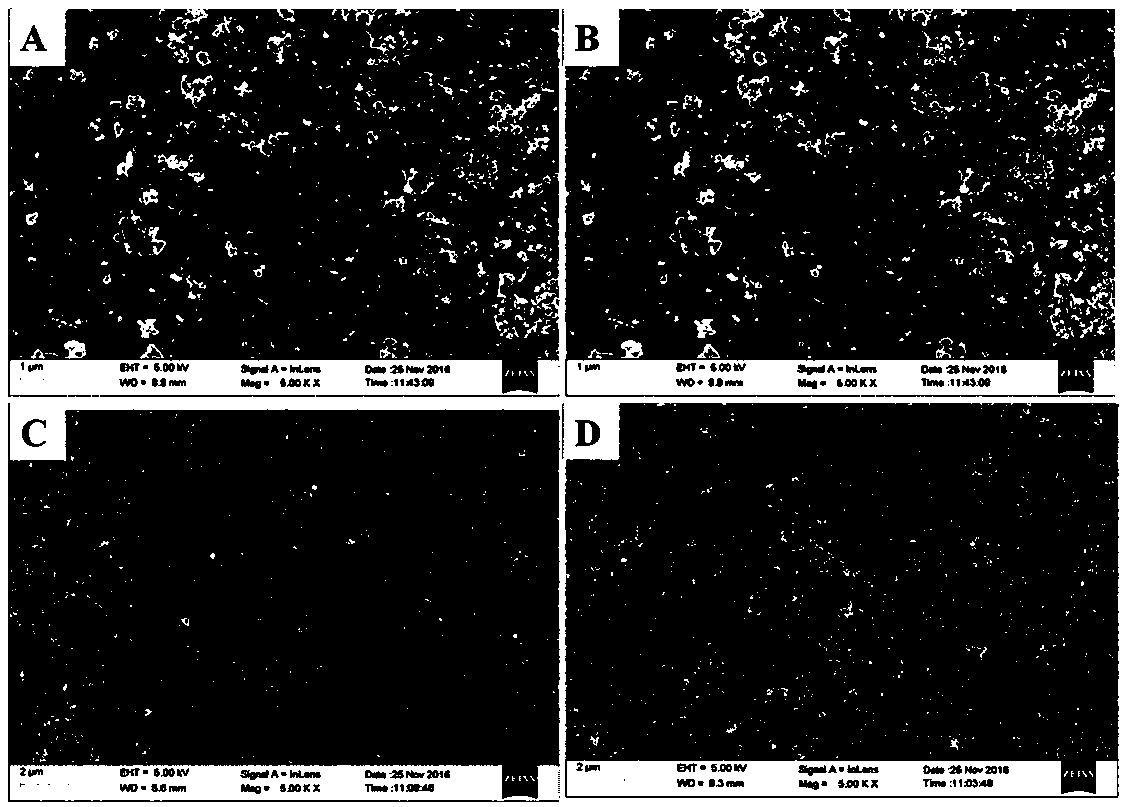

[0034] The preparation method of the involved surface modified bone meal specifically comprises the following steps:

[0035] Natural bovine cancellous bone is calcined and pulverized to obtain porous hydroxyapatite particles after pretreatment, with a particle size of 0.1-2.0 mm and a pore size of 50 nm-150 μm. The surface of the particles is modified by adsorbing medical biomacromolecules , to obtain surface-modified bone meal.

[0036] in:

[0037] The pretreatment of natural bovine cancellous bone is realized by the following steps:

[0038] Take the cancellous bone part of the bovine bone (metaphysis of femur of one-year-old bovine) and cut it into 2cm×2cm×2cm bone pieces. Bone marrow, cartilage and other tissues on the bone block are dry. After immersing the above bone fragments in NaOH solution with a concentration of 0.5 M for 6 h, 30% H 2 o 2 The solution was soaked for 6h, washed with ultrapure water and PBS (pH between 6.0-7.0), and dried. Most of the organic ...

Embodiment 1

[0048] Pre-treatment of calcined bones: select one-year-old bovine femur metaphysis, cut into 2 cm×2 cm×2 cm bone pieces, wash with ultrapure water, put them in a pot and boil them repeatedly for 8 times, during the boiling process Remove bone marrow, cartilage and other tissues on the bone block, and dry. After immersing the above bone in 0.5 M NaOH for 6 h, use 30% H 2 o 2 Soak for 6h, wash with ultrapure water and PBS (pH between 6.0-7.0), and dry. Most of the organic matter in the bone block was removed by the above steps.

Embodiment 2

[0050] Preparation of calcined bone powder and adsorption of medical biomacromolecules: put the prepared bovine bone into a muffle furnace for high-temperature calcination. The calcination process is calcination at 700°C for 4 hours, secondary calcination at 700°C for 3 hours, and washing with PBS until the pH value is 6.5-7.5, pulverize the bone particles with a particle size of 0.1-0.25 mm, place the bone particles in 20 mg / mL sodium hyaluronate solution for negative pressure adsorption for 2 hours, and dry at 37 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com