Novel thermal floor and preparation process thereof

A new type of floor technology, applied in buildings, building structures, floors, etc., can solve the problems of weak floor flatness and pressure resistance, poor performance stability and applicability, unstable heating materials, etc., and achieve good support. and fixing effect, good practicability, strength reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

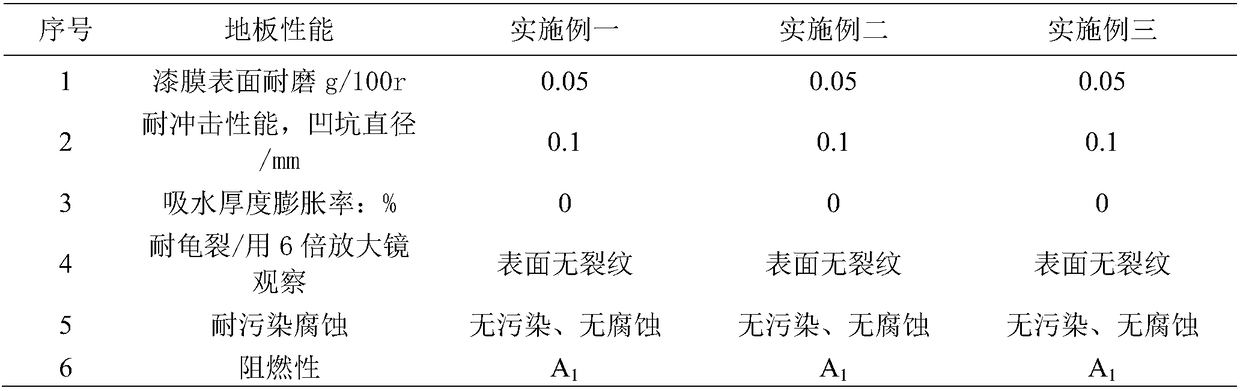

Embodiment 1

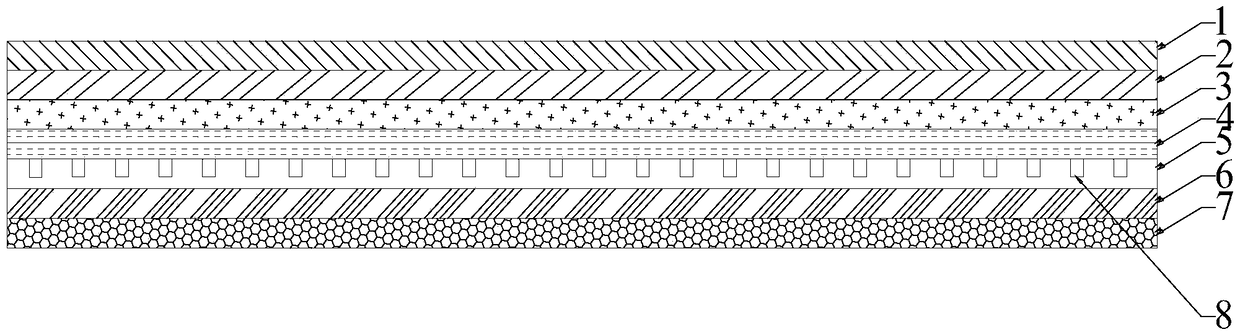

[0033] A new type of heating floor, including: UV curing layer 1, wear-resistant layer 2, printing layer 3, floor substrate 4, reflective layer 6, floor wiring layer 5, sound insulation layer 7, arranged in sequence from top to bottom,

[0034] Several grooves 8 are evenly arranged on the surface of the wiring layer 5 of the bottom board, and the grooves 8 are filled with a blend of polyvinylpyrrolidone-modified polydimethylaminoethyl methacrylate and cage polysilsesquioxane.

[0035] Further, polyvinylpyrrolidone-modified polydimethylaminoethyl methacrylate is prepared by the following method: polyvinylpyrrolidone is dissolved in water, carbon tetrachloride is added, stirred, succinimide and azobisisobutyronitrile are added, at 100 React at ℃ for 24 hours, remove carbon tetrachloride by rotary evaporation, freeze-dry, add water to dissolve, add bromoisobutyryl bromide and dimethylaminoethyl methacrylate, react in the dark at 60°C for 24 hours, add water to dissolve, and freeze...

Embodiment 2

[0048] A new type of heating floor, including: UV curing layer 1, wear-resistant layer 2, printing layer 3, floor substrate 4, reflective layer 6, floor wiring layer 5, sound insulation layer 7, arranged in sequence from top to bottom,

[0049] Wherein the raw material of the floor wiring layer 5 includes the following components by weight: 80 parts of paste polyvinyl chloride resin, 25 parts of thermoplastic polyolefin elastomer, 13 parts of polyetherimide, 12 parts of long glass fiber, and 7 parts of calcium carbonate , 0.8 parts of antioxidant DLTP, 0.8 parts of UV-531 ultraviolet absorber, 1.5 parts of calcium zinc stabilizer, 1.5 parts of fatty acid amide, 1.5 parts of methyl silicone oil, and the components and preparation process of the remaining layers are the same as in Example 1.

Embodiment 3

[0051] A new type of heating floor, including: UV curing layer 1, wear-resistant layer 2, printing layer 3, floor substrate 4, reflective layer 6, floor wiring layer 5, sound insulation layer 7, arranged in sequence from top to bottom,

[0052] Wherein the raw material of floor wiring layer 5 comprises the following components by weight:

[0053] Paste polyvinyl chloride resin 100 parts, thermoplastic polyolefin elastomer 30 parts, polyetherimide 15 parts, polyetherimide 15 parts, long glass fiber 15 parts, calcium carbonate 10 parts, antioxidant DLTP 1.5 parts , 1.5 parts of UV-531 ultraviolet absorber, 2 parts of calcium zinc stabilizer, 2 parts of fatty acid amide, 2 parts of methyl silicone oil, and the rest of the layer components and preparation process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com