Flame-retardant and antistatic EVA (ethyl vinyl acetate) foam composite material and preparation method thereof

A flame-retardant, anti-static, composite material technology, applied in the field of flame-retardant and anti-static EVA foam composite material and its preparation, can solve the problems of flammability and intensified combustion degree, achieve excellent smoke suppression effect, small compression deformation, protection effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing flame retardant and antistatic EVA foam composite material, the concrete steps are:

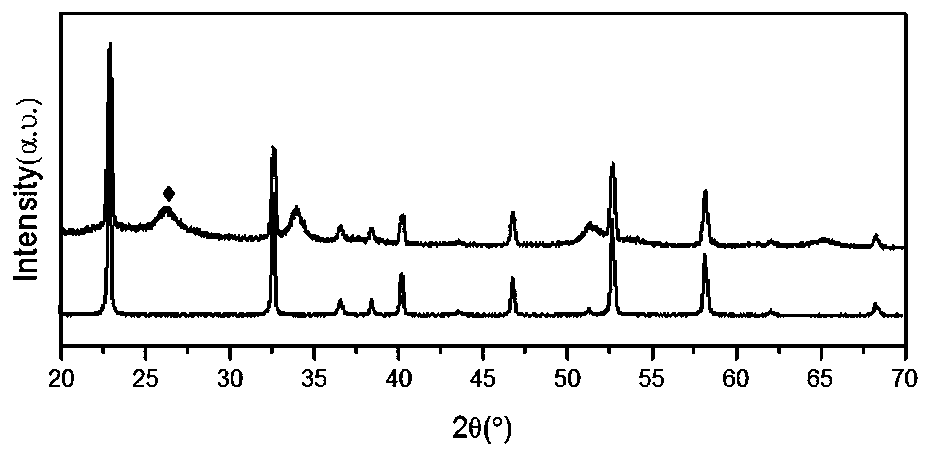

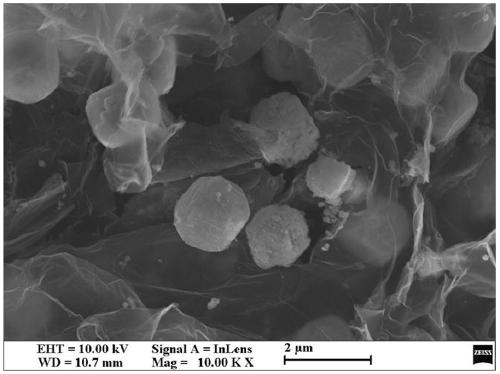

[0038] 1) Add 50 mg of graphene oxide (GO) and 15 mg of polyvinylpyrrolidone (PVP) into 50 mL of deionized water, stir for 30 min, add 50 mg of zinc hexahydroxystannate, stir evenly, and then transfer to a high-pressure reactor , the reaction was stirred at 160 °C for 6 h, suction filtered, and lyophilized;

[0039]2) Preparation of polystyrene nanosphere (PS) template: remove 20mL styrene with 5% sodium hydroxide solution to remove polymerization inhibitor, add 2mL acrylic acid to 125mL deionized water and mix evenly; then Add 0.145g of ammonium persulfate (APS) into the above mixed solution, stir vigorously, under nitrogen protection, heat to 75°C and continue to react for 24h, wash the product with deionized water and absolute ethanol and dry it, and use the dried powder Concentrated sulfuric acid was spheroidized at 45°C for 24 hours, the product was washed ...

Embodiment 2

[0047] A method for preparing flame-retardant and antistatic EVA foam composite material, the specific steps are:

[0048] 1) Add 50 mg of graphene oxide (GO) and 15 mg of polyvinylpyrrolidone (PVP) into 50 mL of deionized water, stir for 30 minutes, then add 50 mg of zinc hexahydroxystannate, stir well and then transfer to the autoclave , stirred and reacted at 160°C for 6h, filtered with suction, and freeze-dried;

[0049] 2) Preparation of polystyrene nanosphere (PS) template: remove 20mL styrene with 5% sodium hydroxide solution to remove polymerization inhibitor, add 2mL acrylic acid to 125mL deionized water and mix evenly; then Add 0.145g of ammonium persulfate (APS) into the above mixed solution, stir vigorously, under nitrogen protection, heat to 75°C and continue to react for 24h, wash the product with deionized water and absolute ethanol and dry it, and use the dried powder Concentrated sulfuric acid was spheroidized at 45°C for 24 hours, the product was washed with...

Embodiment 3

[0057] A method for preparing flame-retardant and antistatic EVA foam composite material, the specific steps are:

[0058] 1) Add 50 mg of graphene oxide (GO) and 15 mg of polyvinylpyrrolidone (PVP) into 50 mL of deionized water, stir for 30 minutes, then add 50 mg of zinc hexahydroxystannate, stir well and then transfer to the autoclave , stirred and reacted at 160°C for 6h, filtered with suction, and freeze-dried;

[0059] 2) Preparation of polystyrene nanosphere (PS) template: remove 20mL styrene with 5% sodium hydroxide solution to remove polymerization inhibitor, add 2mL acrylic acid to 125mL deionized water and mix evenly; then Add 0.145g of ammonium persulfate (APS) into the above mixed solution, stir vigorously, under nitrogen protection, heat to 75°C and continue to react for 24h, wash the product with deionized water and absolute ethanol and dry it, and use the dried powder Concentrated sulfuric acid was spheroidized at 45°C for 24 hours, the product was washed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com