Folium premna puberula dried bean curd and preparation method thereof

A technology of turtle dove leaves and dried bean curd, which is applied in the field of food processing, can solve the problems of inability to shape the material, cannot be made into dried bean curd, and the consistency of the slurry is large, and achieves the effects of good elasticity, low cost and poor emulsification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of turtle dove leaf dried bean curd, comprises following raw materials, all are weight parts;

[0049] 10 parts of soybean protein isolate, 65 parts of ice water, 5 parts of tapioca starch, 7 parts of soybean oil, 0.1 part of TG enzyme, 0.8 parts of dove leaf powder, 0.5 parts of salt, 3 parts of sugar, 0.2 parts of monosodium glutamate, 0.01 parts of I+G, B 0.02 part of base maltol, 0.3 part of chicken paste, 0.1 part of matcha essence, 0.3 part of carrageenan, 0.02 part of calcium carbonate, 0.1 part of sodium carbonate, 0.03 part of sodium iso-Vc.

[0050] Preparation:

[0051] 1) First, add soybean protein isolate to ice water at 0-8°C, chop and mix for 3 minutes at a chopping knife rotating speed of 3500r / min, add soybean oil, increase the chopping knife rotating speed to 4500r / min, and continue chopping and mixing for 2 minutes until it becomes an emulsion;

[0052] 2) Add tapioca starch, colloid, chicken paste, matcha essence, salt, sugar, monosodium glut...

Embodiment 2

[0060] A dried dove leaf bean curd, comprising the following raw materials, all in parts by weight: 10 parts of soybean protein isolate, 60 parts of ice water, 3 parts of tapioca starch, 8 parts of rapeseed oil, 0.2 part of TG enzyme, 1.0 part of dove leaf micropowder, salt 0.6 parts, 4 parts of sucrose, 0.3 parts of MSG, I+G0.02, 0.03 parts of ethyl maltol, 0.2 parts of pork paste, 0.2 parts of green tea essence, 0.3 parts of curdlan, 0.02 parts of calcium carbonate, 0.1 parts of sodium carbonate , 0.03 parts of iso-Vc sodium.

[0061] Preparation method is carried out by the method and step of embodiment 1, and difference is:

[0062] Step 2) The consistency of the slurry out of the pot is 5.5 cm.

[0063] Step 6) Stew with brine for 50 minutes, and the temperature of the stew is 80°C.

[0064] Step 7) Put the stewed blank into a dryer for drying, the drying temperature is 75° C., and the drying time is 40 minutes.

experiment example 1

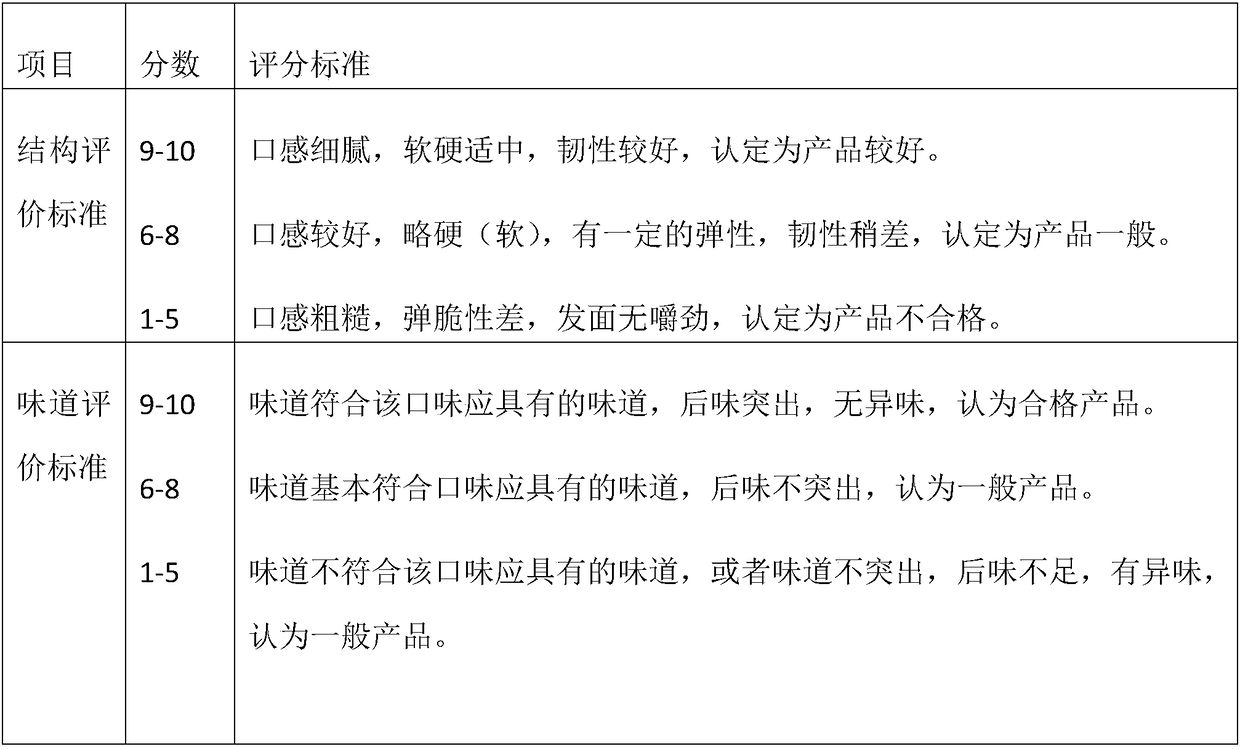

[0071] Experimental example 1: out of the pot consistency

[0072] The slurry obtained in Step 2) of Example 1-2 was compared with the slurry obtained in Step 2) of Comparative Example 1 and 2, and the results were shown in Table 1:

[0073] Table 1 Consistency comparison out of the pot

[0074]

[0075] It can be seen from the consistency comparison results in Table 1 that no inorganic salts and colloids were added in Comparative Example 1, and the water temperature used was 30°C. It has no effect on the consistency of the feed liquid, thereby illustrating that the addition of the dove leaf micro-powder is unfavorable to the consistency and texture of the slurry and affects the production of the product. The formula combined with the process of the present invention greatly reduces the consistency of the product, which is uniform and stable. forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com