A kind of secondary corrosion texturing process on the surface of solar cells

A technology of solar cells and corrosion, which is applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of high silicon wafer thickness requirements, increased costs, complex processes, etc., and achieve uniform and stable texturing and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

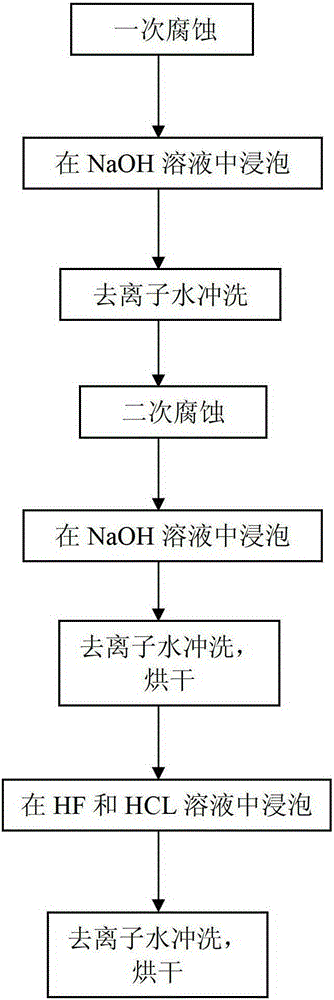

Image

Examples

Embodiment 1

[0038] A secondary corrosion texturing process on the surface of a solar cell, comprising the steps of:

[0039] Step 1: Place the wafer in HNO-rich 3 HF and HNO 3 A corrosion is carried out in the mixed solution; among them, HF and HNO 3 The ratio of the mixed solution is HF:HNO 3 =1:5, corrosion temperature: 19°C, corrosion time: 2 minutes;

[0040] Step 2: Soak the once-etched silicon wafer in NaOH solution; the concentration of NaOH solution is 0.5%, and the soaking time is 30 seconds;

[0041] Step 3: Rinse the silicon wafer soaked in step 2 with deionized water;

[0042] Step 4: Place the wafer in HF-rich HF and HNO 3 The secondary corrosion is carried out in the mixed solution; among them, HF and HNO 3 The ratio of the mixed solution is HF:HNO 3 =50:1, corrosion temperature: 19°C, corrosion time: 3 minutes.

[0043] Step 5: Soak the silicon wafer after secondary etching in NaOH solution to remove porous silicon; wherein the concentration of NaOH solution is 0.5%...

Embodiment 2

[0048] A secondary corrosion texturing process on the surface of a solar cell, comprising the steps of:

[0049] Step 1: Place the wafer in HNO-rich 3 HF and HNO 3 A corrosion is carried out in the mixed solution; among them, HF and HNO 3 The ratio of the mixed solution is HF:HNO 3 =1:3, corrosion temperature: 25°C, corrosion time: 1 minute;

[0050] Step 2: Soak the once-etched silicon wafer in NaOH solution; the concentration of NaOH solution is 1%, and the soaking time is 20 seconds;

[0051] Step 3: Rinse the silicon wafer soaked in step 2 with deionized water;

[0052] Step 4: Place the wafer in HF-rich HF and HNO 3 The secondary corrosion is carried out in the mixed solution; among them, HF and HNO 3 The ratio of the mixed solution is HF:HNO 3 =80:1, corrosion temperature: 15°C, corrosion time: 2 minutes.

[0053] Step 5: Soak the silicon wafer after secondary etching in NaOH solution to remove porous silicon; wherein the concentration of NaOH solution is 1%, and...

Embodiment 3

[0058] A secondary corrosion texturing process on the surface of a solar cell, comprising the steps of:

[0059] Step 1: Place the wafer in HNO-rich 3 HF and HNO 3 A corrosion is carried out in the mixed solution; among them, HF and HNO 3 The ratio of the mixed solution is HF:HNO 3 =1:7, corrosion temperature: 15°C, corrosion time: 4 minutes;

[0060] Step 2: Soak the once-etched silicon wafer in NaOH solution; the concentration of NaOH solution is 0.1%, and the soaking time is 50 seconds;

[0061] Step 3: Rinse the silicon wafer soaked in step 2 with deionized water;

[0062] Step 4: Place the wafer in HF-rich HF and HNO 3 The secondary corrosion is carried out in the mixed solution; among them, HF and HNO 3 The ratio of the mixed solution is HF:HNO 3 =30:1, corrosion temperature: 25°C, corrosion time: 5 minutes.

[0063] Step 5: Soak the silicon wafer after secondary etching in NaOH solution to remove porous silicon; wherein the concentration of NaOH solution is 0.1%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com