Steel adhesive for adhesion of steel materials of coal economizer and preparation method of steel adhesive

A technology for bonding steel glue and economizer, applied in the field of steel bonding glue, can solve the problems of insufficient bonding force and poor high temperature resistance performance of steel bonding glue, and achieve excellent bonding performance, high humidity resistance, and excellent high temperature resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

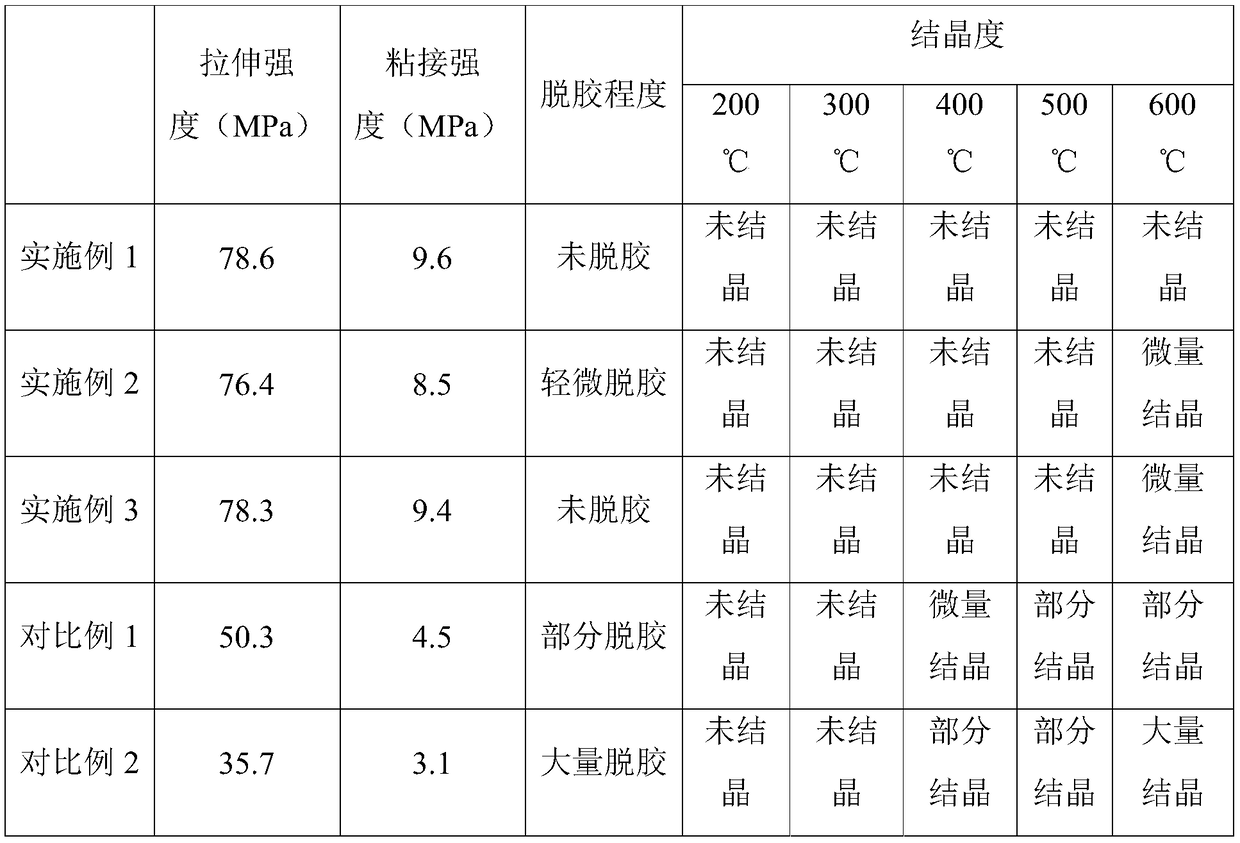

Examples

Embodiment 1

[0026] A steel glue for bonding economizer steel, comprising the following components in parts by weight:

[0027] 55 parts of polyimide, 70 parts of epoxy resin, 50 parts of isopropyl acetate, 28 parts of siloxane, 18 parts of nano-silica, 14 parts of glycerin, 4 parts of phenol oil, 6 parts of polysulfone, azobis 8 parts of isoheptanonitrile, 8 parts of bishydroxyphthalimide, 15 parts of silane coupling agent KH-550 and 5 parts of antioxidant 168.

[0028] The preparation method of above-mentioned glue for sticking steel comprises the following steps:

[0029] (1) Stir and mix epoxy resin and nano-silica according to the formula to form mixed solution A; then mix isopropyl acetate and siloxane to form mixed solution B; mix mixed solution A and mixed solution B at 135°C Stir and mix, then add azobisisoheptanonitrile, continue to stir and react for 4h;

[0030] (2) Mix polyimide, glycerin, phenol oil, antioxidant 168 and polysulfone, then add to the product obtained in step ...

Embodiment 2

[0032] A steel glue for bonding economizer steel, comprising the following components in parts by weight:

[0033] 50 parts of polyimide, 80 parts of epoxy resin, 60 parts of isopropyl acetate, 20 parts of siloxane, 10 parts of nano silicon dioxide, 10 parts of glycerin, 5 parts of phenol oil, 5 parts of polyether, azobis 5 parts of isoheptanonitrile, 5 parts of bishydroxyphthalimide, 10 parts of aluminate and 5 parts of antioxidant 164.

[0034] The preparation method of above-mentioned glue for sticking steel comprises the following steps:

[0035] (1) Stir and mix epoxy resin and nano-silica according to the formula to form mixed solution A; then mix isopropyl acetate and siloxane to form mixed solution B; mix mixed solution A and mixed solution B at 120°C Stir and mix, then add azobisisoheptanonitrile, continue to stir and react for 3h;

[0036] (2) Mix polyimide, glycerin, phenol oil, antioxidant 164 and polyether, then add in the product obtained in step (1), then add ...

Embodiment 3

[0038] A steel glue for bonding economizer steel, comprising the following components in parts by weight:

[0039] 56 parts of polyimide, 80 parts of epoxy resin, 60 parts of isopropyl acetate, 28 parts of siloxane, 20 parts of nano silicon dioxide, 20 parts of glycerin, 10 parts of polysulfone, 15 parts of azobisisoheptanonitrile , 10 parts of bishydroxyphthalimide, 15 parts of ethylene-methyl acrylate and 10 parts of antioxidant CA.

[0040] The preparation method of above-mentioned glue for sticking steel comprises the following steps:

[0041] (1) Stir and mix epoxy resin and nano-silica according to the formula to form mixed solution A; then mix isopropyl acetate and siloxane to form mixed solution B; mix mixed solution A and mixed solution B at 150°C Stir and mix, then add azobisisoheptanonitrile, continue to stir and react for 5h;

[0042] (2) Mix polyimide, glycerin, anti-oxidant CA and polysulfone, then add to the product obtained in step (1), then add bishydroxypht...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com