Polymer-graphite composite membrane, preparation method and application thereof

A polymer film and graphite film technology, applied in the field of composite films, can solve the problems of inability to use corrosion-resistant and high-temperature resistant products, poor corrosion resistance and high temperature resistance, etc., to enhance surface adhesion, excellent corrosion resistance and high temperature resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] According to the second aspect of the present invention, the present invention provides a kind of preparation method of polymer-graphite composite membrane, comprises the steps:

[0066] (a) subjecting the polymer film to plasma treatment;

[0067] (b) Graphite film was sputtered on the plasma-treated polymer film.

[0068] In the preparation method of the polymer-graphite composite film provided by the present invention, the molecular structure of the polymer film is enlarged by first carrying out plasma treatment on the polymer film, and the surface adhesion of the polymer film surface is enhanced, and then sputtering is used to make the polymer film The graphite film is firmly attached to the surface of the polymer film to obtain a polymer-graphite composite film, which makes the polymer-graphite film not only have excellent corrosion resistance and high temperature resistance, but also have lightning protection and anti-glare functions, and also have insulation The...

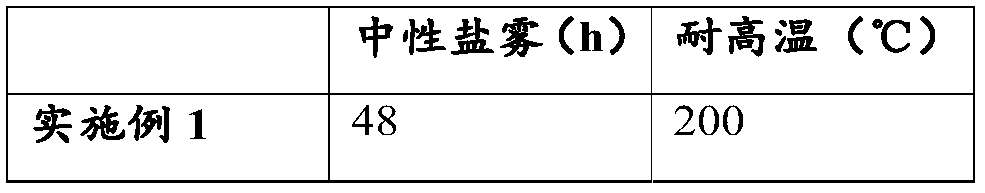

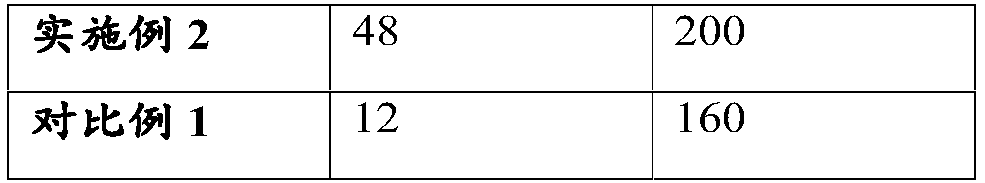

Embodiment 1

[0138] The present embodiment provides a kind of polyester-graphite composite film, and it comprises polyester film, is compounded with graphite film on polyester film, and its preparation method comprises the following steps:

[0139] (a) Preparation of graphite film-copper composite material

[0140] (a1) Carbonization, graphitization and calendering of the polyimide film were performed sequentially to prepare graphite film

[0141] The carbonization treatment includes the following steps: the first stage temperature is raised from room temperature to 300°C, and the heating time is 40 minutes; the second stage temperature is raised from 300°C to 480°C, the heating time is 45 minutes, and the temperature is raised to 480°C and then heat-insulated for 30 minutes ;The temperature in the third stage is raised from 480°C to 600°C, and the heating time is 420min; the temperature in the fourth stage is raised from 600°C to 700°C, and the heating time is 240min; 200min; the sixth s...

Embodiment 2

[0149] This embodiment provides a polyester-graphite composite film, which includes a polyester film, and the polyester film is composited with a graphite film. The difference between its preparation method and Example 1 is that the graphite film-copper composite material is as follows Prepared by steps: brush graphene slurry on copper foil, dry to obtain graphite film-copper composite material; other steps are the same as in Example 1, and will not be repeated here. Comparative example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com