Method for solid-phase photocatalytic oxidation of polycyclic aromatic hydrocarbons

A technology for photocatalytic oxidation and polycyclic aromatic hydrocarbons, which is applied in catalytic cracking, quinone oxidation preparation, cracking, etc., and can solve problems such as full load, high energy consumption, and easy carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The catalytic oxidation of embodiment 1 phenanthrene

[0094] Weigh 0.02g of phenanthrene and 0.6g of sodium bismuthate, add them to the petri dish, then add 14mL of n-hexane to the petri dish, mix the three evenly, then allow the n-hexane to volatilize naturally to obtain a solid phase mixture;

[0095] The solid-phase mixture was irradiated under an ultraviolet lamp with a wavelength of 365 nm, and heated to 80° C. for 8 hours.

Embodiment 2

[0096] The catalytic oxidation of embodiment 2 pyrene

[0097] Weigh 0.02g of pyrene and 0.8g of sodium bismuthate, add them to the petri dish, then add 20mL of ethanol to the petri dish, mix the three evenly, then allow the ethanol to evaporate naturally to obtain a solid phase mixture;

[0098] The solid-phase mixture was placed under a UV lamp with a wavelength of 365 nm, and heated to 80° C. for 8 hours.

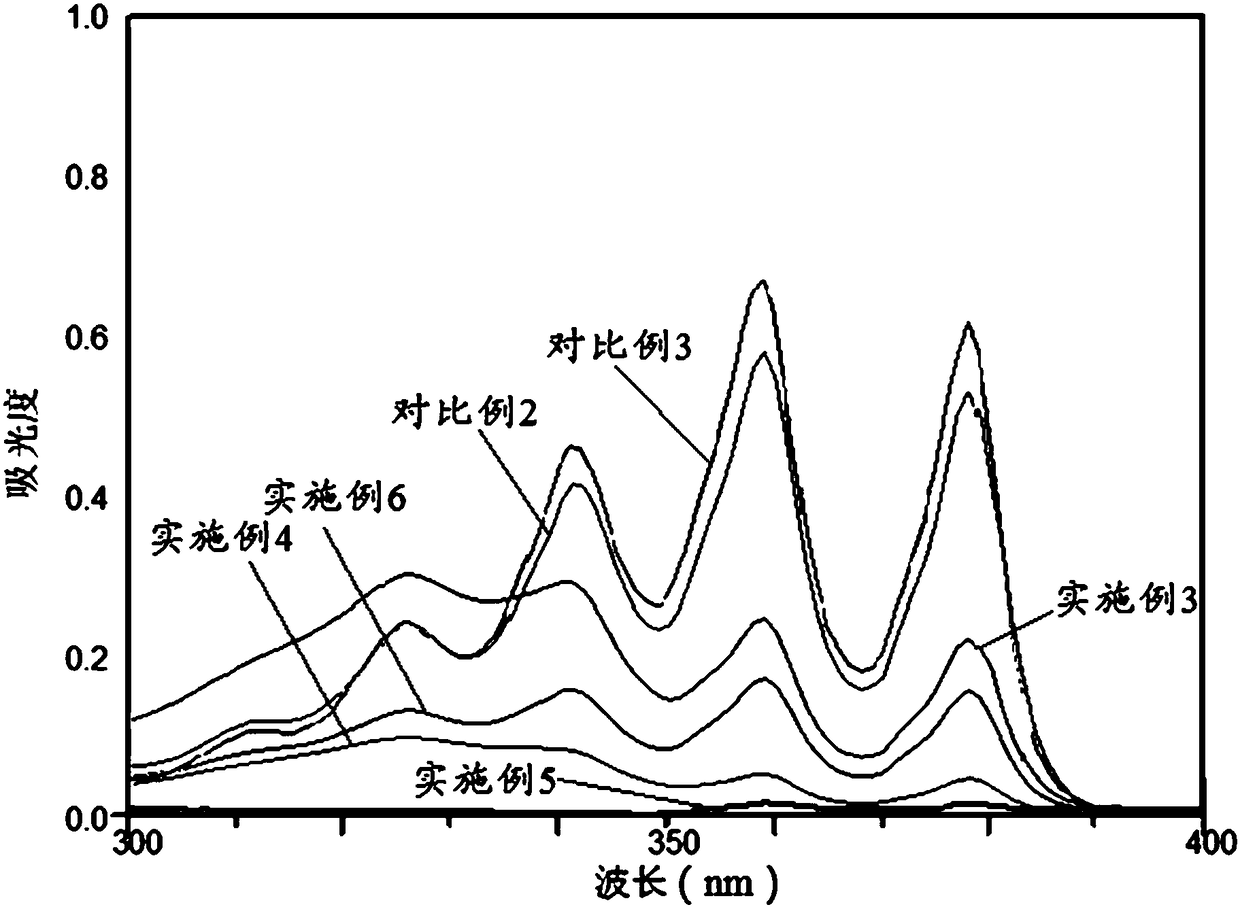

Embodiment 3

[0099] The catalytic oxidation of embodiment 3 anthracene

[0100] Weigh 0.02g of anthracene and 1g of sodium bismuthate, add them to a petri dish, then add 20mL of dichloromethane to the petri dish, mix the three evenly, then allow the dichloromethane to volatilize naturally to obtain a solid phase mixture;

[0101] The solid-phase mixture was placed under a UV lamp with a wavelength of 365 nm, and heated to 60° C. for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com