A metal semi-solid melt extrusion additive manufacturing nozzle

A technology of additive manufacturing and melt extrusion, which is applied in the field of additive manufacturing, can solve the problems of reduced mechanical properties, increased forming costs, and easy oxidation of metal materials, and achieves small solid-liquid phase temperature difference, easy control of the ratio, and solidification The effect of low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

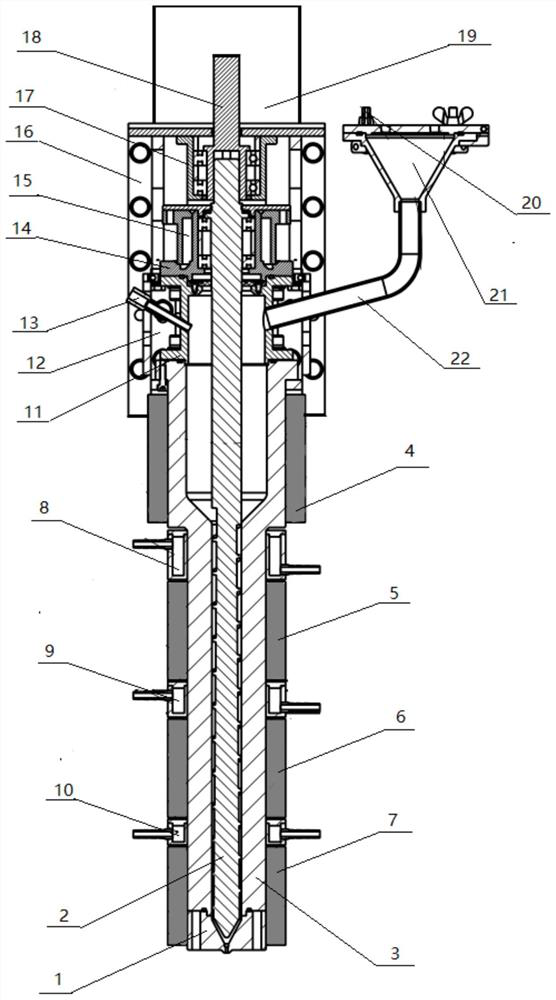

[0037] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0038] A metal semi-solid melt extrusion additive manufacturing nozzle of the present invention, such as figure 1 As shown, it includes: a cavity 3 formed by metal melting and semi-solid, a resistance heating component outside the cavity 3, an extrusion nozzle 1 connected to the lower end of the cavity 3, a support frame 11 and a feeding component located at the upper end of the cavity 3, Two bearing blocks at the upper end of the support frame 11 and two pairs of high-temperature bearings, the shaft coupling 18 in the upper bearing block 14, the speed reducer and the drive motor 19 at the upper end of the shaft coupling 18, and the water cooling ring assembly on the outside of the cavity 3, the container The stirring screw 2 in the chamber 3; the upper end of the stirring screw 2 is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com