Advanced redox water treatment technology based on nitrogen-doped iron-carbon material with core-shell structure and for magnetic field recovery

A core-shell structure, advanced oxidation technology, applied in the fields of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as high energy demand, toxic metal leakage, etc., to overcome easy agglomeration and prolong use. The effect of longevity, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

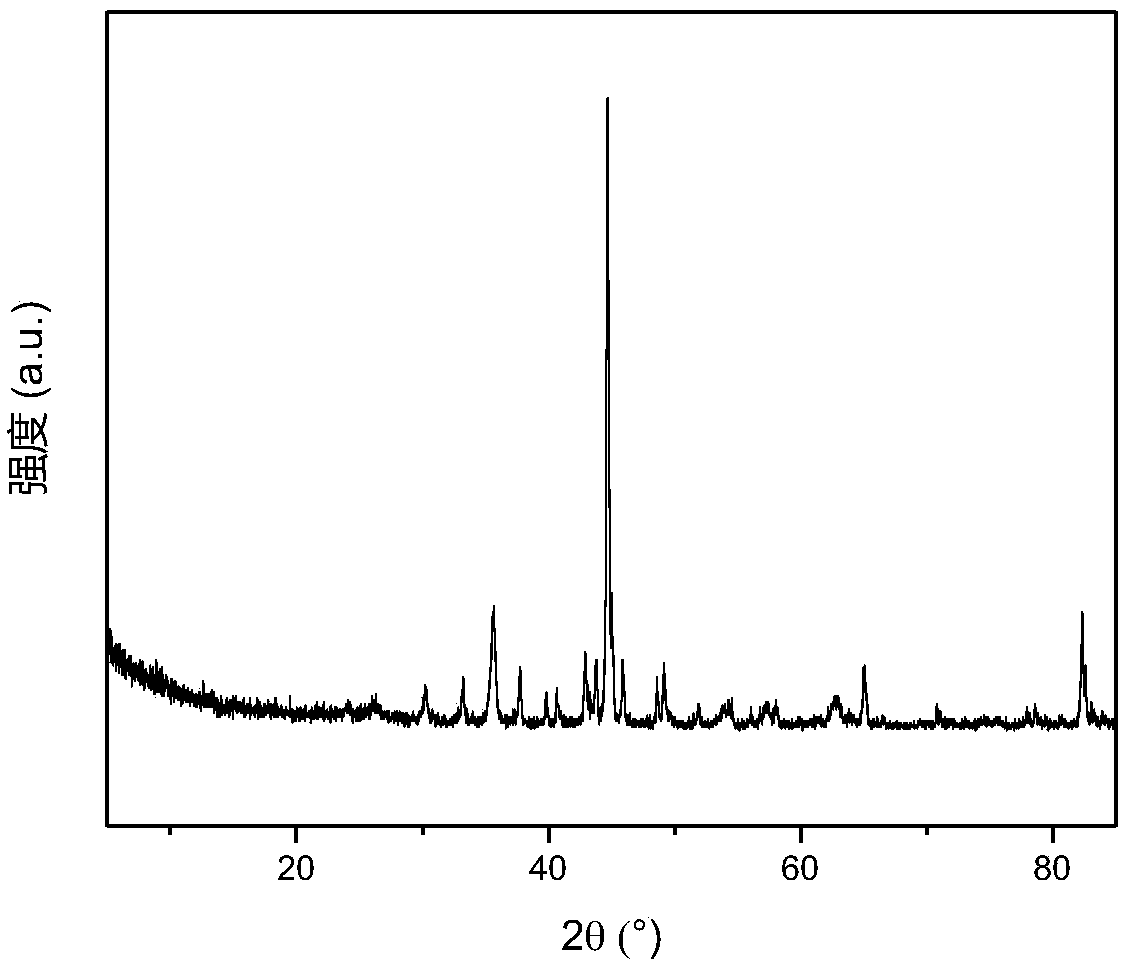

[0020] Example 1 Preparation of a nitrogen-doped iron-carbon composite material with a magnetic core-shell structure

[0021] 674mg of FeCl 3 ·6H 2 O, 452.5 mg of 2-aminoterephthalic acid (NH 2 DBC), 56mL of N,N-dimethylformamide (DMF) was added to the container, and stirred at room temperature to a transparent solution; the solution was transferred to a polytetrafluoroethylene reactor liner with a volume of 100mL. After the shell is sealed, put it in an oven and keep it at 443K for 24 hours; after slowly cooling to room temperature, the mixture is centrifuged, and the obtained crystals are washed with DMF and absolute ethanol respectively; the washed crystals are placed in a vacuum oven at 100°C to keep warm 10 hours. The dried crystals were calcined in a tube furnace in a nitrogen atmosphere, raised to 650°C at a rate of 5°C / min, kept for 3 hours, and cooled naturally to room temperature to obtain a nitrogen-doped crystal with a magnetic core-shell structure. Iron carbon...

Embodiment example 2

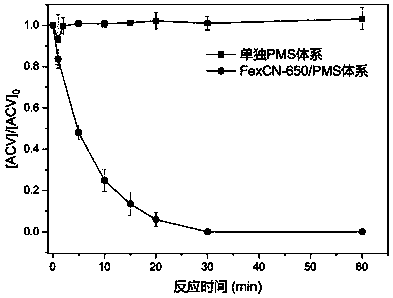

[0022] Implementation Case 2 A nitrogen-doped iron-carbon composite material with a magnetic core-shell structure activates persulfate to degrade acyclovir drug pollutants in water

[0023] The nitrogen-doped iron-carbon composite material with a magnetic core-shell structure prepared in Example 1 was used as a catalyst to activate persulfate to degrade acyclovir refractory drug pollutants in water. A 250mL beaker was used as a reactor, 200mL of reaction solution was configured, and the pH of the solution was adjusted to 7.0 with 0.1mol / L NaOH. Wherein, the dosage of catalyst is 100 mg / L, the concentration of potassium persulfate is 0.65 mmol / L, the concentration of acyclovir is 10 mg / L, and the reaction is carried out with sufficient stirring at room temperature for 1 h.

[0024] In this embodiment, the iron-carbon composite material doped with magnetic core-shell structure and nitrogen-doped activated persulfate can effectively oxidize and degrade acyclovir in water, and the...

Embodiment example 3

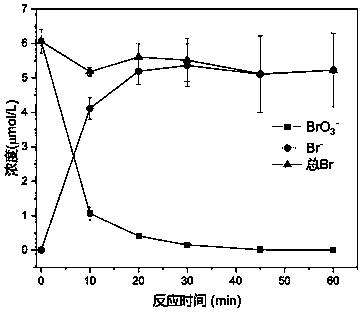

[0025] Implementation Case 3 A nitrogen-doped iron-carbon composite material with a magnetic core-shell structure reduces and removes bromate in water

[0026] The nitrogen-doped iron-carbon composite material with a magnetic core-shell structure prepared in Example 1 was used as a reducing agent to remove bromate in water, and a conical flask with a capacity of 300 mL was selected as the reactor, and then bromate with a concentration of 7.81 μmol / L BrO 3 - Add the solution into the reactor, and then add 500mg / L reducing agent into the reactor. After the addition is complete, stopper the bottle tightly, then vibrate at 200rpm at room temperature, take water samples at regular intervals and filter them through a 0.45μm filter membrane before use. Quantitative Analysis of BrO by Ion Chromatography 3 - and Br - concentration, the result is as Figure 4 . Figure 4 It shows that the nitrogen-doped iron-carbon composite material with a magnetic core-shell structure of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com