Glucan-glucomannan composition

A technology of glucomannan and glucan, used in food science, drug combination, plant raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

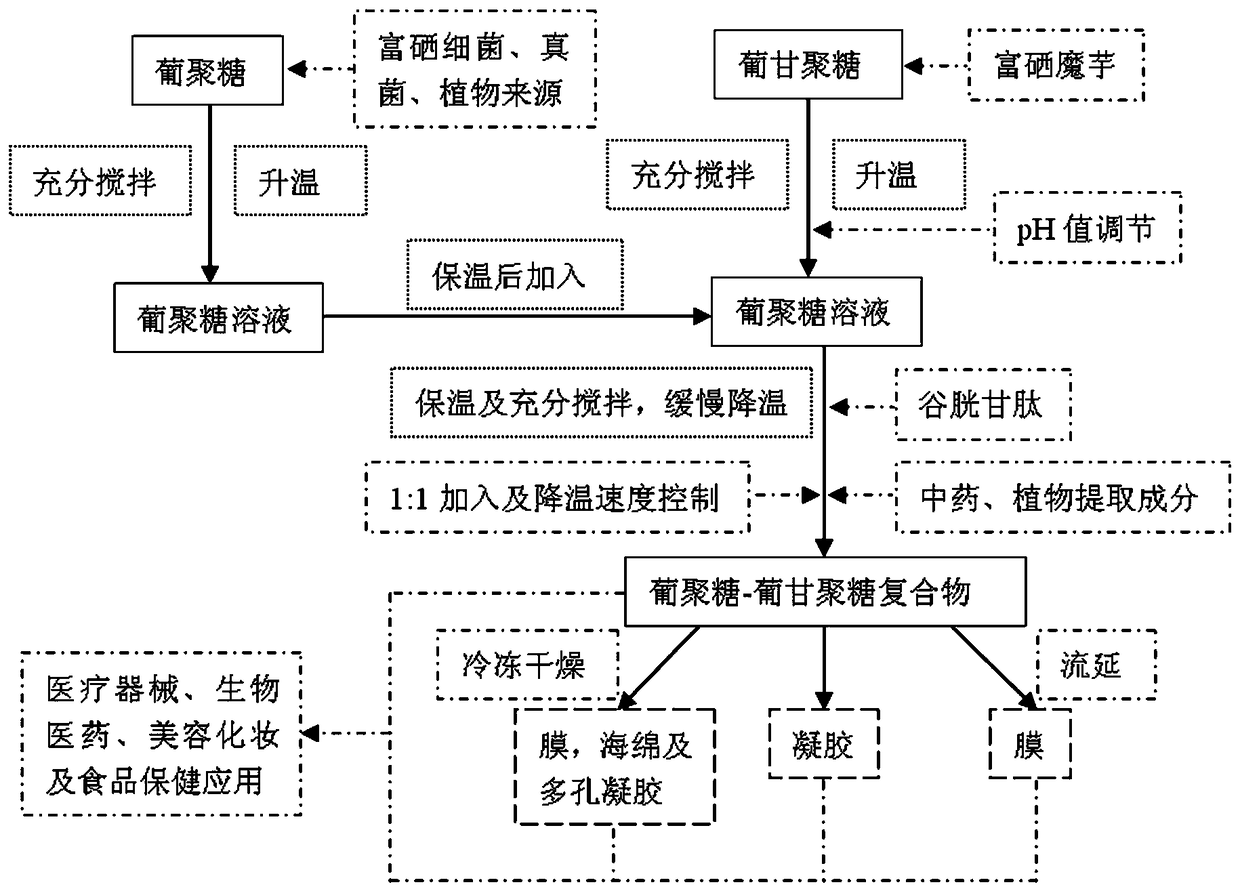

Method used

Image

Examples

Embodiment 1

[0016] The selenium-enriched glutathione-loaded glucan-glucomannan composite colloid contains 0.3% β-glucan and 0.5% glucomannan by mass. β-glucan with a molecular weight range of 10,000-100,000 Daltons was prepared as a solution with a mass percentage of 0.6%, fully stirred and heated to 37°C for 30 minutes; the molecular weight range of 10,000-100,000 Daltons based on polymer The glucomannan prepared from selenium-enriched konjac prepared a solution with a mass percentage of 1.0%, fully stirred and heated to 48°C; the prepared β-glucan solution was slowly added to the above-mentioned thermal insulation at a final ratio of 1:1. In the glucomannan solution, add reduced glutathione to make the final concentration 5 mg / mL, stir well, and keep for 30 minutes; slowly cool down to room temperature to obtain selenium-enriched glutathione dextran-glucomannan Sugar complex colloids are used for skin beauty.

Embodiment 2

[0018] The selenium-enriched glucan-glucomannan composite gel contains 3.6% β-glucan and 4.8% glucomannan by mass. 2,000,000 Daltons of bacterial-derived β-glucan (pre-sterilized) was prepared into a solution with a mass percentage of 7.2%, an appropriate amount of pre-sterilized selenium-enriched yeast powder was added to the solution, and the temperature was fully stirred and heated to 50 ° C. hour; take sterile glucomannan with a molecular weight range of 600,000-1,200,000 daltons based on the polymer to prepare a solution with a mass percentage of 9.6%, stir well, adjust the pH value to 10.5 with 0.5mol / L NaOH solution, fully Stir and heat up to 82°C; slowly add the prepared β-glucan solution to the above-mentioned glucomannan solution in a 1:1 final ratio, stir well, and adjust the pH of the system to 6.8-7.2 with PBS buffer , and the temperature is slowly lowered to room temperature at a rate of less than 1° C. per minute after being incubated for 2 hours to obtain a sel...

Embodiment 3

[0020] The dextran-glucomannan composite membrane, the preparation method includes: taking β-glucan with a molecular weight range of 10,000-2,000,000 Daltons to prepare a solution with a mass percentage of 1.0%, fully stirring and heating up to 45 ℃, incubated for 1 hour; take glucomannan with a molecular weight range of 10,000-1,200,000 Daltons based on the polymer to prepare a solution with a mass percentage of 2.0%, fully stir and heat up to 65 ℃; The prepared β-glucan solution is slowly added to the above-mentioned glucomannan solution that has been kept warm, fully stirred, and after 1 hour of incubation, the mixed system is used for casting and film forming to obtain a dextran-glucomannan composite film. For edible food inner packaging applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com