Method for preparing regenerated cellulose short fiber by carbamate method

A technology of carbamate and regenerated cellulose, which is applied to artificial filaments made of cellulose derivatives, fiber chemical characteristics, spinning solution preparation, etc., which can solve complex process technology, increased manufacturing costs, and low fiber strength and other problems, to achieve the effect of reasonable process connection, high production rate and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

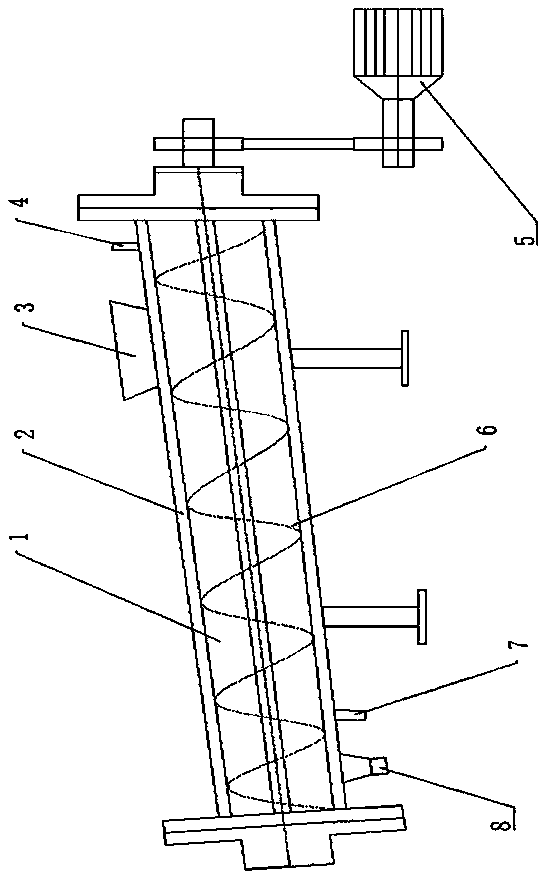

Image

Examples

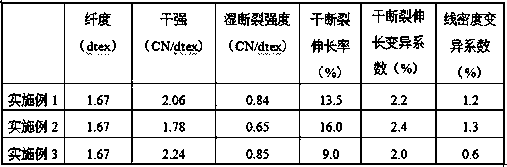

Embodiment 1

[0062] a. Put six batches of cotton pulp and bamboo pulp with an average degree of polymerization of 430 and a methylcellulose content of 98% in a ratio of 8:2 into the urea solution for impregnation. The urea concentration is 30.4g / L, the immersion time is 1.5h, the immersion temperature is 20°C, and the concentration of porridge is 4.5% during immersion. Squeeze and pulverize the soaked porridge solution to obtain cellulose powder with a urea content of 1.77%.

[0063] b. The pulverized cellulose is first pre-dried in a fluidized bed, and then transported and dried in a hot air pipeline to reduce the water content to about 5%, and then use an activation machine to circulate hot air at 190±2°C A rapid activation reaction of 50 min was carried out to obtain cellulose carbamate.

[0064] c. Stir and mix evenly the cellulose carbamate with a -5.2°C solvent compounded with 73.5g / L sodium hydroxide and 15.5g / L zinc oxide. Then, the mixture is placed in a low temperature environm...

Embodiment 2

[0069] a. The impregnation raw material is 7 batches of cotton pulp and wood pulp mixed in a ratio of 7:3. The average methylcellulose content of the pulp is 96%, and the average degree of polymerization is 380. The concentration of the impregnated urea solution is 15.2g / L, the impregnated time is 3h, the impregnated temperature is 24°C, and the urea content in the crushed material is 0.88%.

[0070] b. After the pulverized cellulose wet material goes through two steps of fluidized bed drying and hot air pipeline drying, the moisture content will be 3.51% from 51% after pressing, and then it will be dried under hot air circulation at 180±2℃ for a period of time. 60min high temperature rapid activation.

[0071] c. The activated cellulose carbamate is added to a mixed solvent with a certain concentration of sodium hydroxide and zinc oxide. The concentrations of sodium hydroxide and zinc oxide are 70.9g / L and 17.6g / L respectively, and the temperature is - 4.1°C. The solution w...

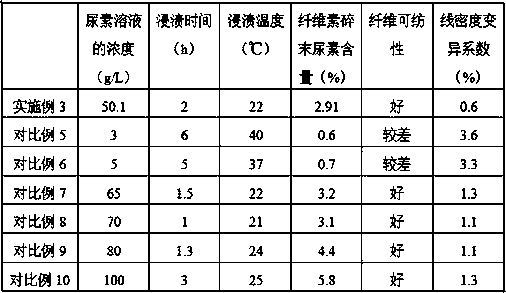

Embodiment 3

[0076] a. Put five batches of cotton pulp and hemp pulp with an average degree of polymerization of 660 and a methylcellulose content of 94% into the urea solution at a ratio of 9:1 for impregnation. The urea concentration is 50.1g / L, the immersion time is 2h, the immersion temperature is 22°C, and the concentration of porridge is 4.5% during immersion. Squeeze and pulverize the soaked porridge solution to obtain cellulose powder with a urea content of 2.91%.

[0077] b. The pulverized cellulose is first pre-dried in a fluidized bed, and then transported and dried in a hot air pipeline to reduce the water content to about 1%, and then use an activation machine to circulate hot air at 160±2°C A rapid activation reaction of 1.5h was carried out to obtain cellulose carbamate.

[0078] c. Stir and mix evenly the cellulose carbamate with a -6.8°C solvent compounded with 65.8g / L sodium hydroxide and 18.5g / L zinc oxide. Then the mixture is placed in a low-temperature environment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com