A nickel-magnesium-chromium composite oxide catalyst for hydrogen production by autothermal reforming of acetic acid

A composite oxide and autothermal reforming technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve carbon deposition and catalyst deactivation and other problems, to achieve the effect of improving catalytic activity, promoting dehydrogenation process and oxidation process, and improving reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

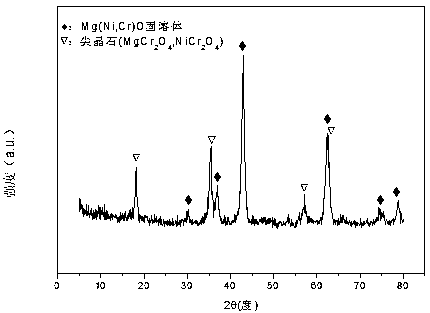

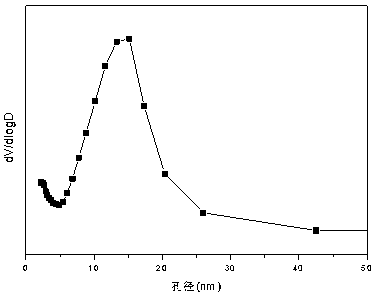

Embodiment 1

[0030] Weigh 8.903g of Cr(NO 3 ) 3 9H 2 , 11.411g of Mg (NO 3 ) 2 ·6H 2 O and 2.005g of Ni(NO 3 ) 2 .6H 2 O, add 73.60ml of deionized water to make solution #1. Accurately weigh 9.427g of NaOH and 1.610g of Na 2 CO 3 , was added to 250ml of deionized water to prepare solution #2. Subsequent steps are the same as in reference example 1, obtain a typical structure such as attached figure 1 Containing MgCr shown 2 o 4 and NiCr 2 o 4 Spinel structure and Mg-Ni-Cr-O solid solution, such as attached figure 2 The shown pore size distribution is mainly concentrated in the range of 10–20 nm for the mesoporous composite oxide CUT-NMC-201 catalyst. The weight composition of the catalyst is as follows: the nickel oxide content is 14.9%, the magnesium oxide content is 55.1%, and the chromium oxide content is 30.0%.

[0031] The catalyst CUT-NMC-201 has been tested on the activity of acetic acid autothermal reforming. When the reaction conditions are normal pressure, space...

Embodiment 2

[0033] Accurately weigh 8.566g of Cr(NO 3 ) 3 9H 2 O, 12.484g of Mg(NO 3 ) 2 ·6H 2 O and 2.336g of Ni(NO 3 ) 2 .6H 2 O, add 75.00ml of deionized water to make solution #1. Accurately weigh 9.681g of NaOH and 1.603g of Na 2 CO 3 , was added to 225ml of deionized water to prepare solution #2. Subsequent steps are the same as in reference example 1, obtain a typical structure such as attached figure 1 shown and attached figure 2 Containing MgCr shown 2 o 4 and NiCr 2 o 4 Mesoporous composite oxide catalyst CUT-MNC-301 with spinel structure and Mg-Ni-Cr-O solid solution and pore size distribution concentrated in the range of 10-20nm. The weight composition of the catalyst is as follows: the nickel oxide content is 14.9%, the magnesium oxide content is 50.1%, and the chromium oxide content is 35.0%.

[0034] The catalyst CUT-NMC-301 was investigated by the autothermal reforming activity of acetic acid. The reaction conditions were normal pressure, space velocity 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com