A dual-initiation curing system for improving printing layer texture and its preparation method

A printing layer and system technology, applied in the field of 3D printing, can solve problems such as uneven exposure within the layer, and achieve the effect of solving uneven curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

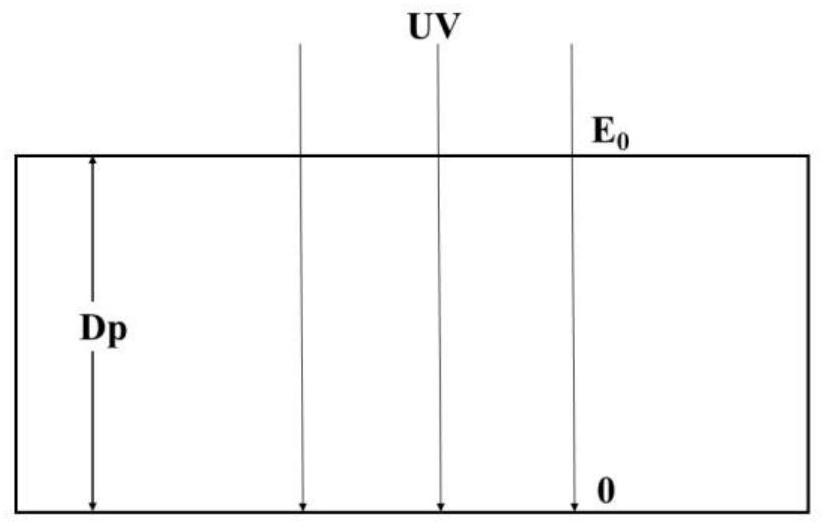

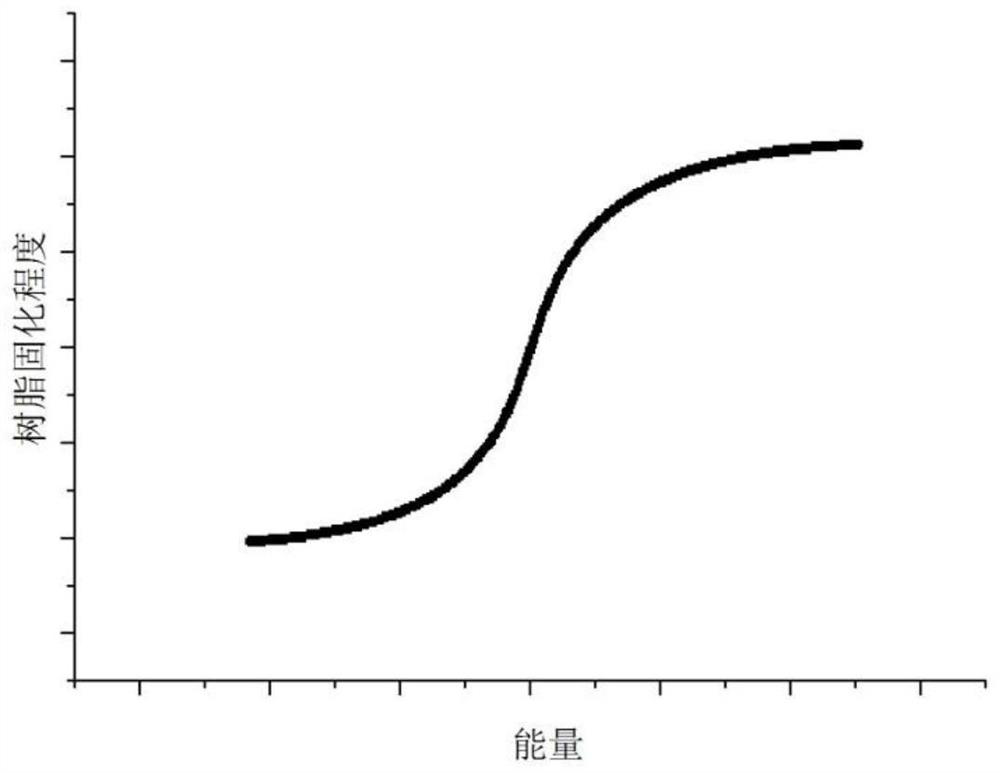

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] By weight percentage, active oligomer urethane acrylate 25%, polyester acrylate 20%, polyethylene glycol diacrylate 20%, reactive diluent acryloyl morpholine 15%, acrylate isopropyl ester 10%, light Initiator phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 3%, leveling agent acrylate compound 2%, defoamer polyethylene glycol 400 2%, light absorber 2,4 - Mix 1% dihydroxybenzophenone and 2% thermal initiator dibenzoyl peroxide, stir at a medium speed of 500 rpm for 5 hours, and then stir at a high speed of 1200 rpm for 0.5 hour to obtain a uniform photocuring system.

[0033] Design a three-dimensional solid model through modeling software, use the slicing software to slice the model according to the designed curing layer thickness, import the sliced files into the control software of the light-curing rapid prototyping machine, and place the light-curing system in the SLA light Under the curing rapid prototyping machine, the wavelength is 355nm for point-by-point expos...

Embodiment 2

[0035]Percentage by weight, reactive oligomer urethane acrylate 20%, polyester acrylate 25%, polyethylene glycol diacrylate 20%, reactive diluent acryloyl morpholine 10%, isopropyl acrylate 15%, photoinitiated Agent 2,4,6-trimethylbenzoyl ethyl phosphonate 3%, leveling agent polyether modified dimethyl siloxane solution 2%, defoamer modified polydimethyl siloxane 2 %, light absorber 2-hydroxy-4-n-octyloxybenzophenone 1%, thermal initiator azobisisobutyronitrile 2%, mix at medium speed 800 rpm for 15 hours, then high speed 1200 rpm Stir for 1 h to obtain a uniform photocuring system.

[0036] Design a three-dimensional solid model through modeling software, use slicing software to slice the model according to the designed curing layer thickness, import the sliced files into the control software of the light-curing rapid prototyping machine, and place the light-curing system in the DLP light Under the curing rapid prototyping machine, the wavelength is 365nm for point-by-poin...

Embodiment 3

[0038] Percentage by weight, reactive oligomer urethane acrylate 20%, polyester acrylate 20%, polyethylene glycol diacrylate 25%, reactive diluent acryloyl morpholine 12%, isopropyl acrylate 13%, photoinitiated Agent diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide 3%, leveling agent polyester modified dimethyl siloxane solution 2%, defoamer aliphatic amide 2%, light Absorbent 2-(2ˊ-hydroxy-5ˊ-methylphenyl)benzotriazole 1%, thermal initiator azobisisoheptanonitrile 2%, mixed at medium speed 1000 rpm / min for 10h, then high speed 1500 rpm / min and stirred for 0.7h to obtain a uniform photocuring system.

[0039] Design a three-dimensional solid model through modeling software, use the slicing software to slice the model according to the designed curing layer thickness, import the sliced files into the control software of the light-curing rapid prototyping machine, and place the light-curing system in the SLA light Under the curing rapid prototyping machine, the wavelength is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com