Determination method for detecting chromium element in fish feed product by fusion-plasma spectral method

A technology of plasma spectroscopy and fish feed, applied in the field of analysis and determination of chromium in fish feed samples, can solve the problems of incomplete chromium oxidation, cumbersome, time-consuming, etc., and achieve high accuracy, simple operation steps, and complete sample decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

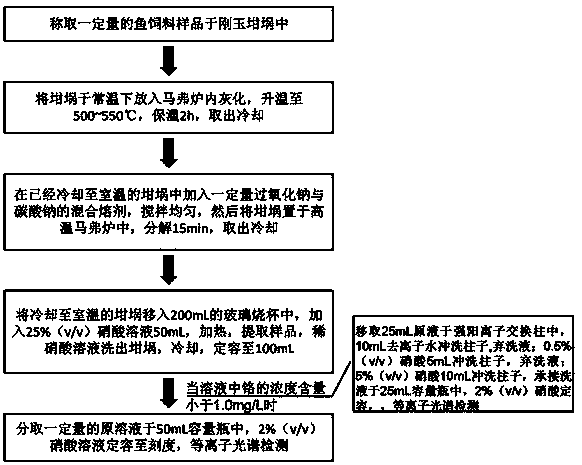

[0030] Such as figure 1 Shown, the steps of the present invention are as follows:

[0031] Weigh 1.000-5.000g of the fish feed sample to be tested in a corundum crucible, put the crucible in a muffle furnace at room temperature for ashing, raise the temperature to 500-550°C, keep it warm for at least 2 hours, and take it out to cool;

[0032] Add 3-4g of mixed flux of sodium peroxide and sodium carbonate to the crucible that has been cooled to room temperature, stir well, then place the crucible in a muffle furnace at 700-750°C, decompose for 15 minutes, take it out and cool;

[0033] Move the crucible cooled to room temperature into a 200mL glass beaker, add 25% ( v / v ) nitric acid solution 50mL, then put the beaker on the electric heating plate, extract the sample, 2% ( v / v ) Wash out the crucible with nitric acid solution, cool it down, and set the volume in a 100mL volumetric flask;

[0034] Take 5.00mL of the solution after constant volume, put it in a 50.0mL volumetr...

Embodiment 2

[0041] The steps of the present invention are as follows:

[0042] Weigh 1.000-5.000g of the fish feed sample to be tested in a corundum crucible, put the crucible in a muffle furnace at room temperature for ashing, raise the temperature to 500-550°C, keep it warm for at least 2 hours, and take it out to cool;

[0043] Add 3-4g of mixed flux of sodium peroxide and sodium carbonate to the crucible that has been cooled to room temperature, stir well, then place the crucible in a muffle furnace at 750°C, decompose for 15 minutes, take it out and cool;

[0044] Move the crucible cooled to room temperature into a 200mL glass beaker, add 25% ( v / v) nitric acid solution 50mL, then put the beaker on the electric heating plate, extract the sample, 2% ( v / v ) Wash out the crucible with nitric acid solution, cool it down, and set the volume in a 100mL volumetric flask;

[0045] Take 5.00mL of the solution after constant volume, put it in a 50.0mL volumetric flask, add 2% ( v / v ) Nitri...

Embodiment 3

[0052] The steps of the present invention are as follows:

[0053] Weigh 1.000-5.000g of the fish feed sample to be tested in a corundum crucible, put the crucible in a muffle furnace at room temperature for ashing, raise the temperature to 500-550°C, keep it warm for at least 2 hours, and take it out to cool;

[0054] Add 3-4g of mixed flux of sodium peroxide and sodium carbonate to the crucible that has been cooled to room temperature, stir well, then place the crucible in a muffle furnace at 700-750°C, decompose for 15 minutes, take it out and cool;

[0055] Move the crucible cooled to room temperature into a 200mL glass beaker, add 25% ( v / v ) nitric acid solution 50mL, then put the beaker on the electric heating plate, extract the sample, 2% ( v / v ) Wash out the crucible with nitric acid solution, cool it down, and set the volume in a 100mL volumetric flask;

[0056] Pipette 25mL sample solution, blank solution, and chromium standard series solution into the strong cati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com