Method for continuous production of propylene oxide by direct oxidation of propylene with hydrogen peroxide through tubular reactors

A tubular reactor, propylene oxide technology, applied in chemistry/physics/physicochemical fixed reactors, chemical instruments and methods, organic chemistry, etc., can solve the impact of propylene oxide production, in the development stage, the amount of co-products Major problems, to achieve the effect of increasing reaction safety, reducing decomposition, improving reaction conversion rate and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with example, a kind of method that utilizes tubular reactor to directly oxidize propylene with hydrogen peroxide to continuously produce propylene oxide is described in detail.

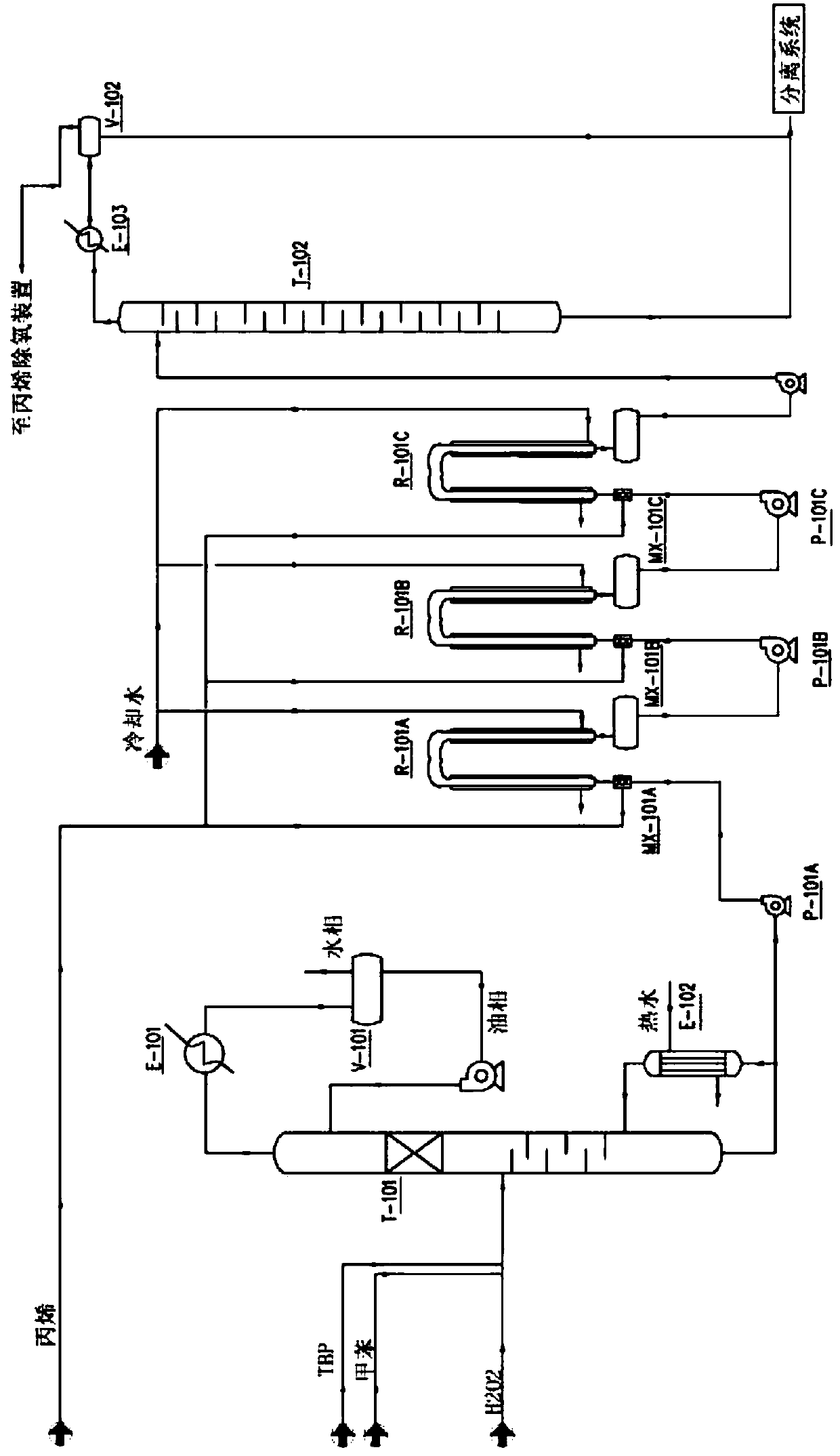

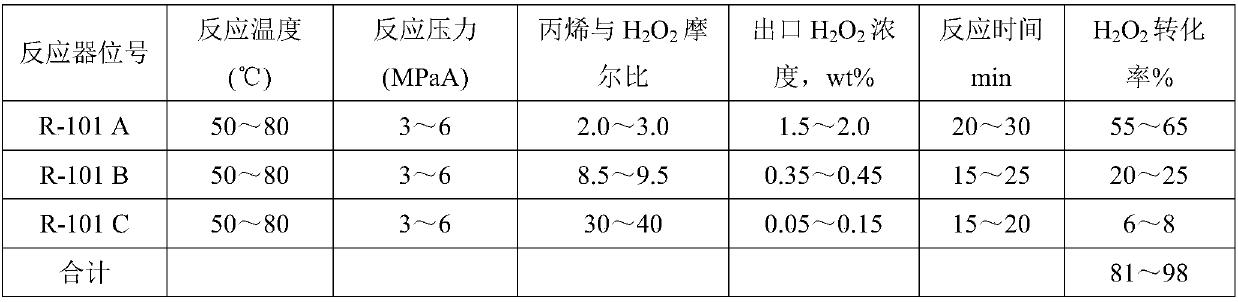

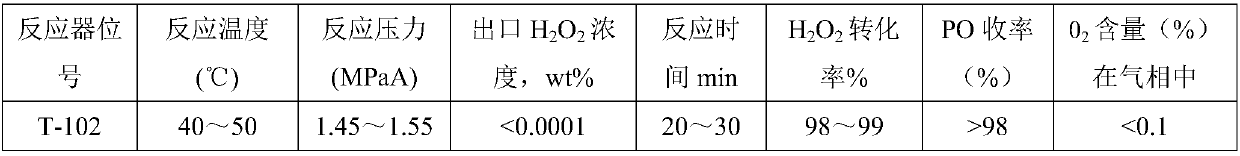

[0015] like figure 1 Shown, a kind of method that utilizes tubular reactor to make hydrogen peroxide directly oxidize propylene to continuously produce propylene oxide comprises the following steps: (1) catalyst phosphotungstic heteropolyacid quaternary ammonium salt mixes with hydrogen peroxide, organic solvent, in dehydration tower T -101 azeotropic dehydration, the top product of the dehydration tower T-101 is condensed by the dehydration tower condenser E-101 and separated by the reflux tank V-101, the water phase is discharged, and the oil phase is refluxed; (2) The bottom of the dehydration tower T-101 The dehydrated mixed liquor flows through the series of three-stage tubular reactors R-101A, R-101B, and R-101C in sequence, and each stage of tubular reactor is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com