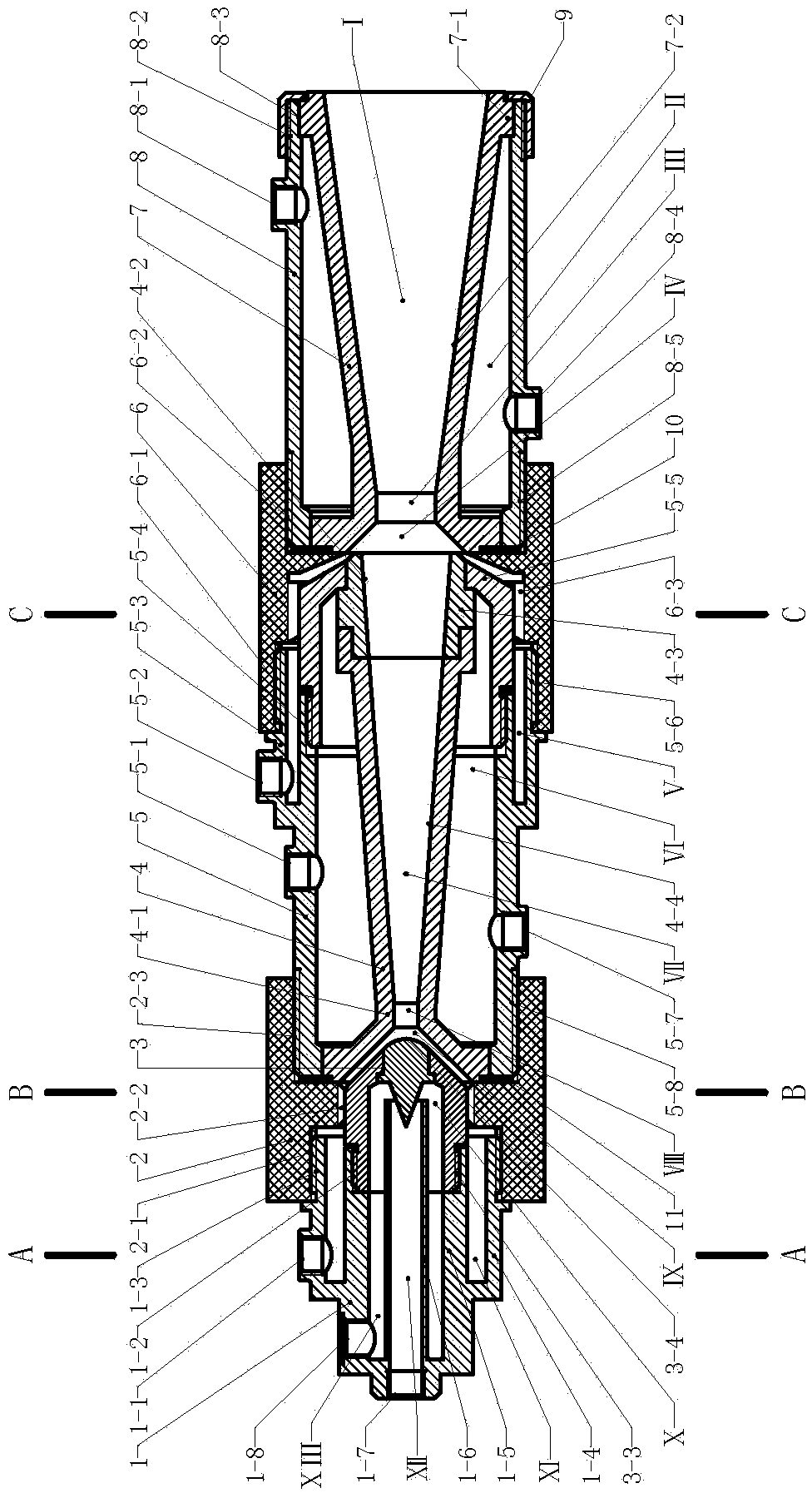

Plasma torch of double-stage nozzle structure

A plasma and two-stage nozzle technology, applied in the direction of plasma, electrical components, etc., can solve the problems of low heating efficiency and incomplete decomposition, and achieve improved heating efficiency, high processing temperature, improved heating efficiency and decomposition ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

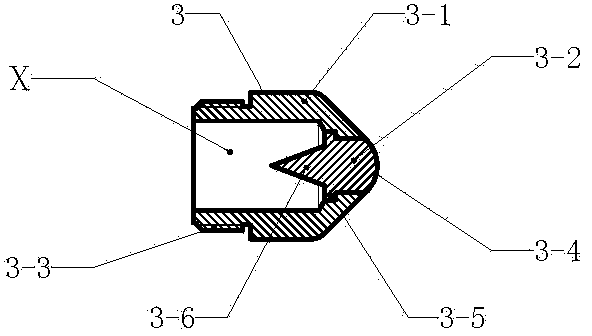

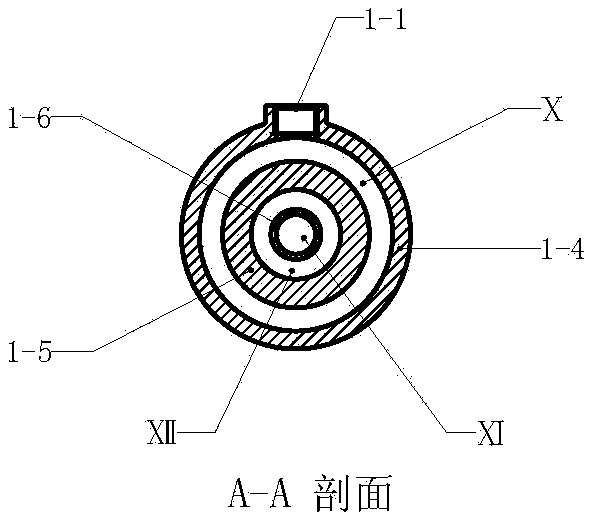

[0017] Example 1 figure 1 In the illustrated embodiment, a plasma torch with a two-stage nozzle structure consists of a back seat (1), a cathode (3), a first insulating gun frame (2), a first nozzle (4), a first tube sleeve (5), the second insulating gun frame (6), the second nozzle (7) and the second sleeve (8), wherein the rear seat (1) is a rotary structure, and the rear seat (1) rotates The front end of the body structure center has a cathode interface (1-2), and there is a cooling water circuit in the rotating body structure of the rear seat (1). 6) Extending into the cooling cavity (Ⅹ) of the cathode (3), the inner space of the guide tube (1-6) forms the cooling water supply channel (Ⅻ), and the outer space of the guide tube (1-6) forms the cooling The return water channel (ⅩⅢ), the cooling water supply channel (Ⅻ) is connected to the cooling water input port (1-7), and the cooling water return channel (ⅩⅢ) is connected to the cooling water output port (1-8). 1) Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com