Preparation method of refractory high-entropy alloy powder

A high-entropy alloy and refractory technology, which is applied in the field of preparation of refractory high-entropy alloy powder, can solve the problems of low efficiency and long preparation cycle, and achieve the effects of low cost, avoiding long time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

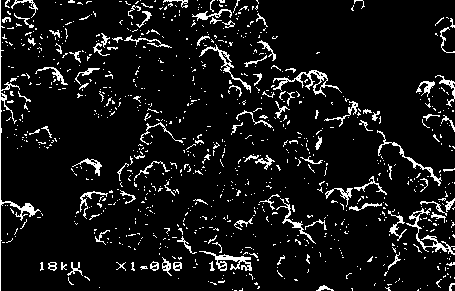

Image

Examples

Embodiment 1

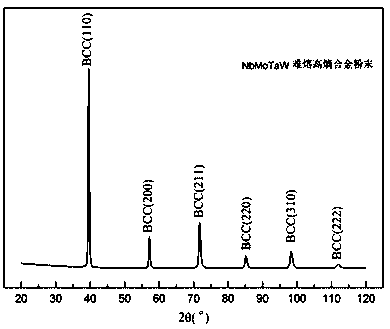

[0018] A refractory high-entropy alloy powder is composed of four high-melting refractory metals, niobium, molybdenum, tantalum and tungsten. The atomic percentage of each component is 25%, and the material is expressed as Nb 25 Mo 25 Ta 25 W 25 . The alloy powder preparation steps are as follows:

[0019] (1) Weigh four refractory metal powders of niobium, molybdenum, tantalum and tungsten according to atomic percentage. The particle size of the four powders is all less than 0.010mm, and the purity is greater than 99.5%.

[0020] (2) Ball mill and mix the proportioned powder in a high-energy ball mill for 1 hour. The ball to material ratio is 4:1.

[0021] (3) Put the mixed powder in a graphite mold, and perform pressureless sintering in a spark plasma sintering furnace. The protective atmosphere is argon, the sintering process parameters are: vacuum degree 5Pa, sintering temperature 1680°C, holding time 10min, DC pulse ratio 12:2.

[0022] (4) Crushing again with a ba...

Embodiment 2

[0025] A refractory high-entropy alloy powder is composed of titanium, niobium, molybdenum, tantalum and tungsten, five refractory metals with high melting points, and the atomic percentage of each component is 20%, and the material is expressed as Ti 20 Nb 20 Mo 20 Ta 20 W 20 . The alloy powder preparation steps are as follows:

[0026] (1) Five kinds of refractory metal powders of titanium, niobium, molybdenum, tantalum and tungsten are weighed according to atomic percentage. The particle size of the four powders of niobium, molybdenum, tantalum and tungsten are all less than 0.010mm, and the particle size of titanium powder is less than 0.076mm. The purity of metal powder is greater than 99.5%.

[0027] (2) Ball mill and mix the proportioned powder in a high-energy ball mill for 2 hours. The ball to material ratio is 4:1.

[0028] (3) Put the mixed powder in a graphite mold, and perform pressureless sintering in a spark plasma sintering furnace. The protective atmos...

Embodiment 3

[0031] A refractory high-entropy alloy powder is composed of six refractory metals with high melting point, namely chromium, titanium, niobium, molybdenum, tantalum and tungsten. The atomic percentage of each component is 16.7%, and the material is expressed as Ti 16.7 Nb 16.7 Mo 16.7 Ta 16.7 W 16.7 . The alloy powder preparation steps are as follows:

[0032] (1) Weigh five kinds of refractory metal powders of chromium, titanium, niobium, molybdenum, tantalum and tungsten according to atomic percentage. It is 0.076mm, and the purity of all metal powders is greater than 99.5%.

[0033] (2) Ball mill and mix the proportioned powder in a high-energy ball mill for 2.5 hours. The ball-to-material ratio is 5:1.

[0034] (3) Put the mixed powder in a graphite mold, and perform pressureless sintering in a spark plasma sintering furnace. The protective atmosphere is argon, the sintering process parameters are: vacuum degree 5Pa, sintering temperature 1520°C, holding time 12min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com