Silica/lignin porous carbon composite material, preparation method thereof and application in lithium ion battery anode material

A technology of silica and composite materials, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc. The electrode structure is destroyed and the active material is difficult to form the SEI film, etc., to achieve a good application prospect, suppress the volume expansion, and enhance the volume expansion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

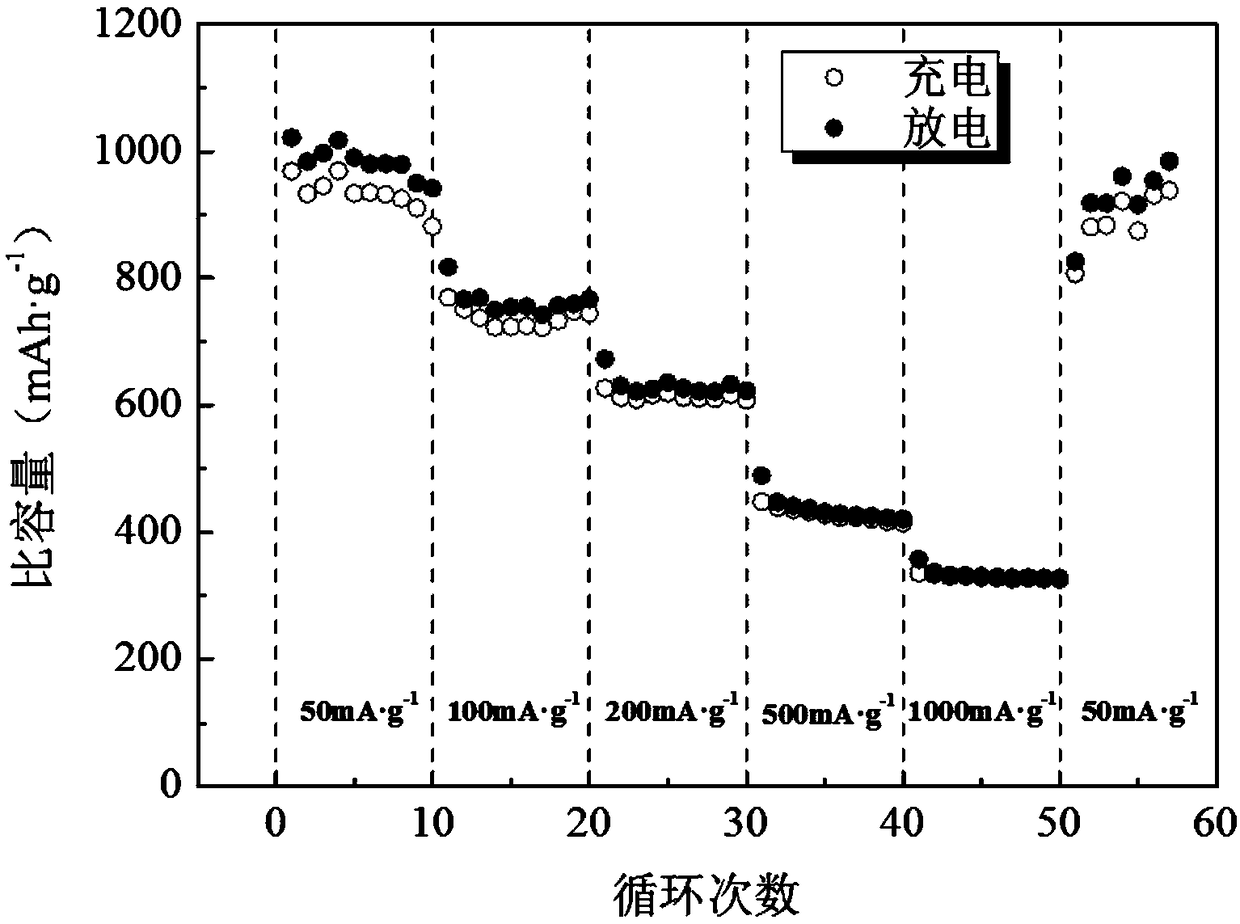

[0055] Take 1g of alkali lignin solid powder and 0.01g of dodecanol and mix it into 200mL of absolute ethanol to dissolve; add 0.25g of nano-silica (particle size 10nm) and mix evenly; 200 mL of water was added at a high speed, the precipitate was separated by centrifugation, and the silica / lignin mixture was obtained after drying.

[0056] Take 1g of the silica / lignin mixture and place it in a hydrothermal reaction kettle, add 100mL of water with pH=2, mix well, heat to 120°C, react for 1h, filter and separate to obtain a precipitate, dry it and place it in a nitrogen atmosphere to raise the temperature Keep at 600°C for 2 hours to prepare the silica / lignin-carbon composite material, then place it in 1mol / L hydrofluoric acid and stir for 4 hours, then wash with deionized water, filter and spray dry to obtain the two Silica / lignin porous carbon composites.

Embodiment 2

[0058]Take 0.5g of alkali lignin and 0.5g of enzymolytic lignin solid powder and mix them with 0.1g of n-butanol and add to 50mL of absolute ethanol to dissolve; add 1.0g of nano silicon dioxide (particle size 100nm) and mix evenly, stir 500mL of water was added at a rate of 30mL / min, the precipitate was separated by centrifugation, and the silica / lignin mixture was obtained after infrared drying.

[0059] Take 1g of the silica / lignin mixture and place it in a hydrothermal reaction kettle, add 10mL of water with pH=4, mix well, heat to 200°C, react for 3h, filter and dry the precipitate, and then place it in a nitrogen atmosphere to raise the temperature Keep at 900°C for 2 hours to obtain a silica / lignin carbon composite material, then place it in 0.5mol / L hydrofluoric acid and stir for 24 hours, then wash with deionized water, filter and dry to obtain the two Silica / lignin porous carbon composites.

Embodiment 3

[0061] Take 5g of enzymolytic lignin solid powder and 0.05g of ethylene glycol, mix it with 250mL of absolute ethanol and dissolve it; add 5g of nano-silicon dioxide (particle size 30nm) and mix evenly, and stir at 10mL / min Add 750 mL of water at a high rate, centrifuge to separate the precipitate, and dry to obtain a silica / lignin mixture.

[0062] Take 5g of the silica / lignin mixture and place it in a hydrothermal reaction kettle, add 50mL of water with pH = 3, mix well, heat to 160°C, react for 1h, filter and dry the precipitate, and then place it in a nitrogen atmosphere to raise the temperature Keep at 700°C for 2 hours to obtain a silica / lignin carbon composite material; then place it in 1mol / L hydrofluoric acid and stir for 4 hours, then wash with deionized water, filter and dry to obtain carbon dioxide Silicon / lignin porous carbon composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com