Method for preparing immobilized lipase by using porous nano-gold as carrier, and application of immobilized lipase

A technology of porous nano-gold and fat immobilization, applied in biochemical equipment and methods, immobilized on or in inorganic carriers, enzymes, etc., can solve the problems of poor stability of free enzymes, difficult separation of products, and inability to recycle, etc. High reuse efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method for immobilizing lipase with porous nano-gold as a carrier, comprising the following steps:

[0034] 1. Preparation of porous gold nanomaterials

[0035] (1) Cut a gold-silver alloy material with a gold-silver atomic ratio of 48:52 into a 1cm×1cm square sample, weighing 5 mg. The sample was placed in concentrated nitric acid with a mass concentration of 68%, and corroded at room temperature for 24 hours. Wash the sample five times with ultrapure water until neutral, and dry the sample in a vacuum freeze dryer.

[0036] (2) Put the above sample into the annealing furnace, set the temperature at 200°C, and start timing for two hours after the temperature rises to the preset temperature. The annealing furnace was closed, and the porous nano-gold (NPG) material was obtained after natural cooling.

[0037] Under the above process conditions, a nanoporous material with a three-dimensional continuous structure can be prepared. Such as figure 1 shown. ...

Embodiment 2

[0049] A preparation method for immobilizing lipase with porous nano-gold as a carrier, comprising the following steps:

[0050] 1. Preparation of porous gold nanomaterials

[0051] (1) Cut a gold-silver alloy material with a gold-silver atomic ratio of 48:52 into a 1cm×1cm square sample, weighing 5mg. The sample was placed in concentrated nitric acid with a mass concentration of 70%, and corroded at room temperature for 24 hours. Wash the sample 6 times with ultrapure water until neutral, and put it into a vacuum freeze dryer to dry the sample.

[0052] (2) Put the above sample into the annealing furnace, set the temperature at 250°C, and start timing for two hours after the temperature rises to the preset temperature. The annealing furnace was closed, and the porous nano-gold (NPG) material was obtained after natural cooling.

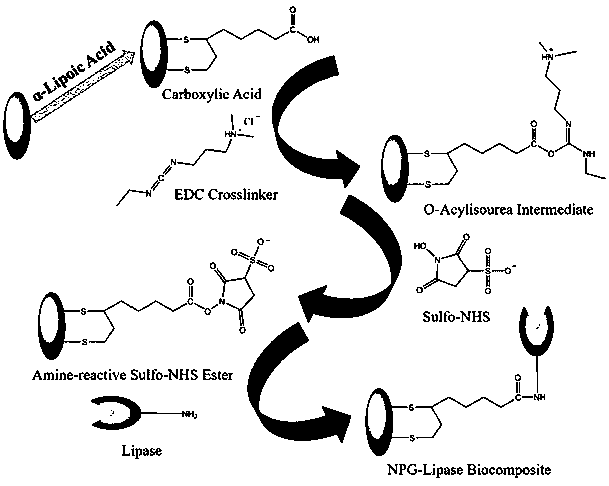

[0053] 2. Covalently linked lipase with gold nanomaterials

[0054] (1) Dissolve α-lipoic acid solid in absolute ethanol solution to prepare 10ml...

Embodiment 3

[0061] A preparation method for immobilizing lipase with porous nano-gold as a carrier, comprising the following steps:

[0062] 1. Preparation of porous gold nanomaterials

[0063] (1) Cut a gold-silver alloy material with a gold-silver atomic ratio of 50:50 into a 1cm×1cm square sample, weighing 5mg. The sample was placed in concentrated nitric acid with a mass concentration of 75%, and corroded at room temperature for 16 hours. Wash the sample five times with ultrapure water until neutral, and dry the sample in a vacuum freeze dryer.

[0064] (2) Put the above sample into the annealing furnace, set the temperature at 300°C, and start timing for 1.5 hours after the temperature rises to the preset temperature. The annealing furnace was closed, and the porous nano-gold (NPG) material was obtained after natural cooling.

[0065] Under the above process conditions, a nanoporous material with a three-dimensional continuous structure can be prepared. Such as figure 1 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com