Concrete de-molding agent

A technology of concrete release agent and auxiliary agent, which is applied in the field of concrete, can solve the problems of reducing the strength of concrete, and achieve the effects of enhancing surface strength, increasing specific surface area, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

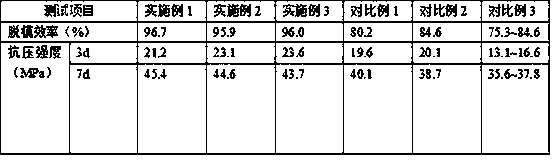

Examples

preparation example Construction

[0032] Excipients: Mix sodium citrate, potassium chloride, and sodium secondary alkyl sulfonate at a mass ratio of 5:1~2:1 to obtain the excipients. A preparation method for a cross-linked complex, comprising the steps of:

[0033] (1) Mix polyether polyol and mannitol according to the mass ratio of 4:1~2, dehydrate at 110~125°C and 0.1MPa for 2~4 hours, then cool down to 40~55°C to obtain the pretreated product, take Add diphenylmethane diisocyanate to the pretreated substance at a mass ratio of 5:1~2 and mix, react at 80~90°C for 3~5h, cool down to 40~65°C, add mixed oil with 40~60% of the pretreated substance, Mix the silane coupling agent with 10~15% of the pretreatment substance, stir at 250~350r / min for 20~40min, and let it stand for 3~6h to obtain a prepolymer for later use;

[0034](2) According to the mass ratio of 1:0.5~0.8:12~18, take carbomer, polyallylamine, and water, mix and stir in the container, let it stand at room temperature for 4~8h, at 65~80℃, at 300~450...

Embodiment 1

[0045] Auxiliary: Mix bentonite, kaolin and zeolite at a mass ratio of 5:1:1 to obtain the auxiliary.

[0046] Grinding aid: triethanolamine.

[0047] Silane coupling agent: silane coupling agent KH550.

[0048] Mixed oil: Mix castor oil, rapeseed oil, and olive oil in a mass ratio of 4:1:1 to get mixed oil.

[0049] Activation medium: in parts by mass, take 20 parts of glucose, 30 parts of peptone, 20 parts of potato, 1 part of Na 2 HPO 4 , 1 part of NaH 2 PO 4 , 20 parts of agar, 900 parts of water, and sterilized at 121°C for 15 minutes to obtain the activated medium.

[0050] Fermentation medium: in parts by mass, take 20 parts of glucose, 30 parts of peptone, 30 parts of yeast powder, 2 parts of citric acid, and 1 part of Na 2 HPO 4 , 1 part of NaH 2 PO 4 , 20 parts of agar, 900 parts of water, and sterilized at 121°C for 15 minutes to obtain the fermentation medium.

[0051] Excipients: mix sodium citrate, potassium chloride, and sodium secondary alkyl sulfonat...

Embodiment 2

[0064] Auxiliary: Mix bentonite, kaolin and zeolite at a mass ratio of 5:1:2 to obtain the auxiliary.

[0065] Grinding aid: Triisopropanolamine.

[0066] Silane coupling agent: silane coupling agent KH560.

[0067] Mixed oil: Mix castor oil, rapeseed oil and olive oil according to the mass ratio of 6:1:2 to get the mixed oil.

[0068] Activation medium: in parts by mass, take 40 parts of glucose, 55 parts of peptone, 30 parts of potato, 4 parts of Na 2 HPO 4 , 4 parts NaH 2 PO 4 , 30 parts of agar, 1000 parts of water, and sterilized at 121°C for 20 minutes to obtain the activated medium.

[0069] Fermentation medium: by mass parts, take 40 parts of glucose, 55 parts of peptone, 50 parts of yeast powder, 5 parts of citric acid, 4 parts of Na 2 HPO 4 , 4 parts NaH 2 PO 4 , 30 parts of agar, 1000 parts of water, and sterilized at 121°C for 20 minutes to obtain the fermentation medium.

[0070] Excipients: mix sodium citrate, potassium chloride, and sodium secondary al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com