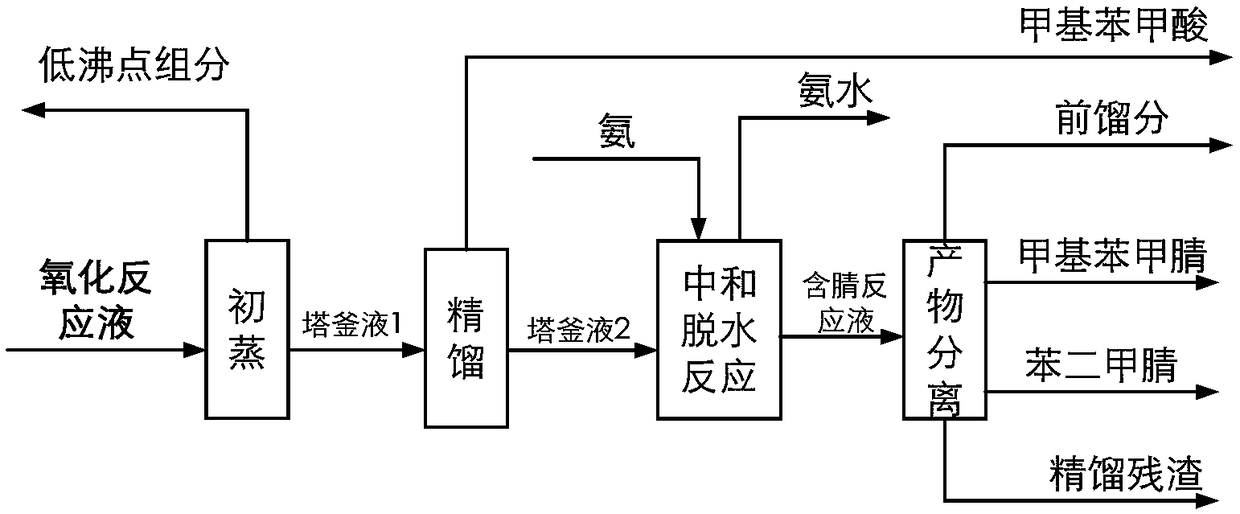

Method for coproducing methylbenzoic acid, methyl benzonitrie and phthalonitrile

A technology of methyl benzoic acid and methyl benzonitrile, which is applied in chemical instruments and methods, purification/separation of carboxylic acid nitrile, preparation of carboxylate, etc. The problem of low yield and other problems can be avoided, and the effect of avoiding rectification residue, reducing the amount of three wastes and improving the yield is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

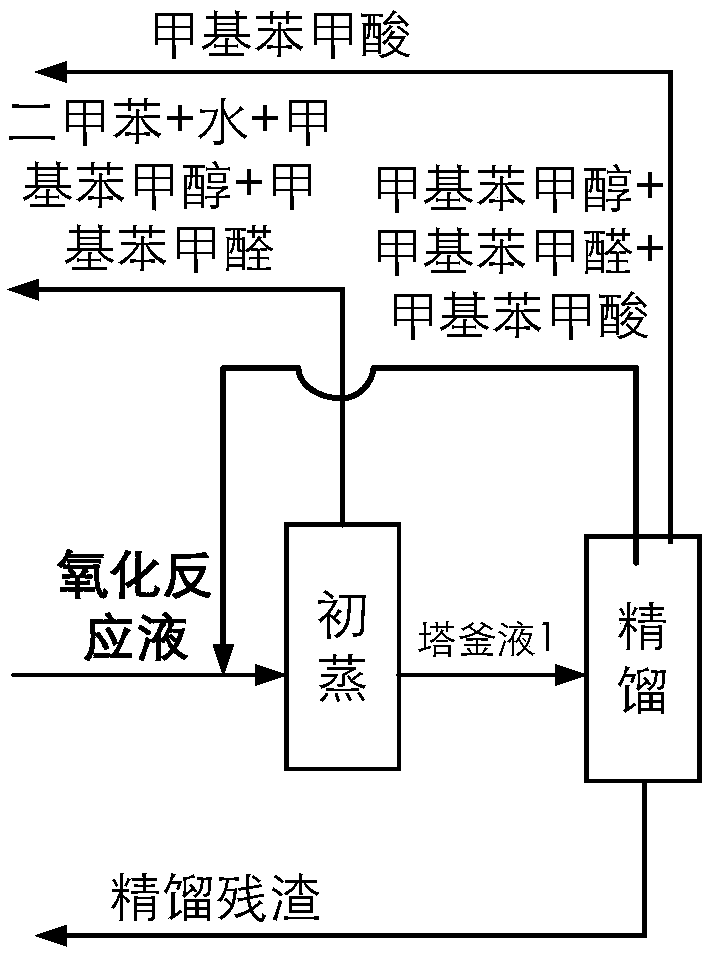

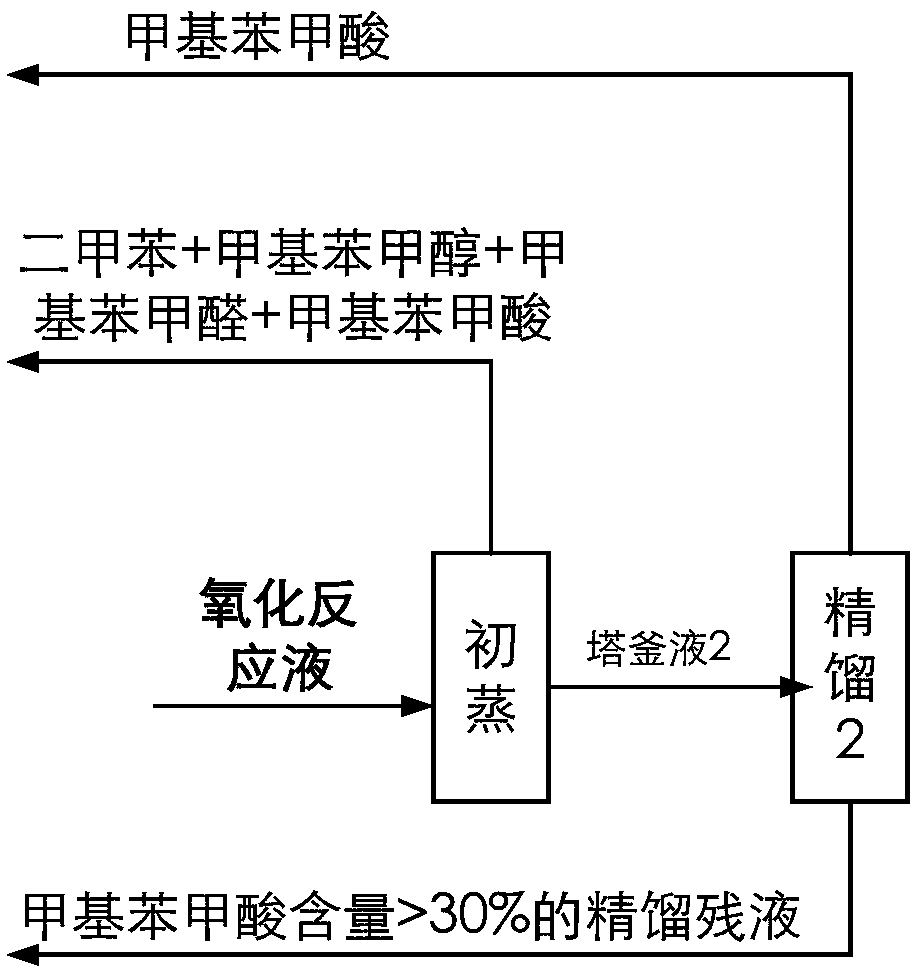

Method used

Image

Examples

Embodiment 1

[0101] The catalyst that dissolves in the fresh p-xylene that adds in the oxidation reactor is cobalt naphthenate, metal phthalocyanine (R with general formula (IV) structure 1 =CH 3 CH 2 , R 2 =H, M=Mn), the metalloporphyrin (R 1 = R 2 = H, R 3 =CH 3 , M=Cu) mixture, the total concentration is 75ppm, the reaction temperature is 180°C, the reaction pressure is 2MPa, the oxygen-containing gas is the oxygen-enriched air of 24% oxygen concentration, the residence time of the reactants in the oxidation reactor is adjusted to make the The conversion rate of xylene was 42%, and the oxidation reaction solution was obtained. At this time, the mass percentage of each component in the reaction solution obtained by HPLC analysis is listed in Table 1. In the initial distillation tower, the boiling point in the oxidation reaction liquid is lower than all components of p-methylbenzyl alcohol for rectification separation, and when the p-methylbenzyl alcohol content reaches 0.06wt% in t...

Embodiment 2

[0104] The catalyst dissolved in fresh p-xylene fed to the oxidation reactor was MnO 2 And cobalt acetylacetonate, total concentration is 350ppm, and reaction temperature is 150 ℃, and reaction pressure is 1MPa, oxygen-containing gas concentration 21%, operation process is identical with embodiment 1, and difference is that the conversion rate control of p-xylene is 50% , the mass percent content of p-methylbenzyl alcohol in the initial distillation tower still liquid is controlled to be 0.07%. The mass percent composition of each component that HPLC analysis obtains in the reaction solution is listed in Table 1, and the quality, composition and the content of methylbenzoic acid in the first distillation column tower bottom liquid that obtains are listed in the table 2.

[0105] Add the liquid from the above-mentioned initial distillation tower to the rectification tower for rectification, and obtain 889.4 g of p-toluic acid product with a purity of 99.0% at the top of the to...

Embodiment 3

[0107] Add the catalyst dissolved in the fresh p-xylene in the oxidation reactor to be N-hydroxyphthalimide, cobalt isooctanoate, metal phthalocyanine (R with general formula (IV) structure 1 =OH,R 2 =H, M=Ru) and metalloporphyrins (R 1 = R 3 = H, R 2 =OH,M 1 = M 2 =Mn) mixture, the total concentration is 10000ppm, the reaction temperature is 116 ° C, the reaction pressure is 0.2MPa, the oxygen-containing gas is pure oxygen, the operation process is the same as in Example 1, and the difference is that the conversion rate of p-xylene is controlled as 60%, and the mass percent content of p-methylbenzyl alcohol in the initial distillation tower bottom liquid is controlled to be 0.10%. The mass percent composition of each component that HPLC analysis obtains in the reaction solution is listed in Table 1, and the quality, composition and the content of methylbenzoic acid in the first distillation column tower bottom liquid that obtains are listed in the table 2.

[0108] Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com