Bismuth titanate based perovskite phase thermosensitive ceramic composite material as well as preparation method and application thereof

A technology of perovskite phase and heat-sensitive ceramics, which is applied in the direction of non-adjustable metal resistors, resistors, electrical components, etc., can solve problems such as aging and irreversible changes in temperature resistance characteristics, and achieve high density, small grains, Grainy and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Dissolve bismuth nitrate in ethylene glycol, stir in a water bath at a constant temperature of 40°C until completely dissolved, and prepare a 0.5mol / L alkoxide solution for later use;

[0025] b. Using sodium acetate and zinc acetate with a molar percentage of Na:Zn=9:1 as raw materials, mix and dissolve in absolute ethanol, prepare a 0.5mol / L ion mixed solution, and set aside;

[0026] c. Dissolve tetrabutyl titanate in absolute ethanol to prepare a 1mol / L solution, add acetylacetone dropwise to stabilize tetrabutyl titanate, stir evenly to obtain a mixed solution, and set aside;

[0027] d, the solution obtained in step a is slowly dripped into the solution obtained in step b, after mixing evenly, add citric acid complexing agent, citric acid complexing agent and total metal ion Bi 3+ 、Na + , Zn 2+ and Ti 4+ The molar ratio is 1.5:1;

[0028] e. Slowly add the mixed solution obtained in step c to the mixed solution obtained in step d, stir while adding dropwise...

Embodiment 2

[0034] a. Dissolve bismuth nitrate in ethylene glycol, stir in a water bath at a constant temperature of 70°C until completely dissolved, and prepare a 0.5mol / L alkoxide solution for later use;

[0035] b. Using sodium acetate and zinc acetate with a molar percentage of Na:Zn=1:9 as raw materials, mix and dissolve in absolute ethanol, prepare a 0.5mol / L ion mixed solution, and set aside;

[0036] c. Dissolve tetrabutyl titanate in absolute ethanol to prepare a 1mol / L solution, add acetylacetone dropwise to stabilize tetrabutyl titanate, stir evenly to obtain a mixed solution, and set aside;

[0037] d, the solution that step a obtains is slowly added dropwise in the solution that step b obtains, after mixing uniformly, add citric acid complexing agent, citric acid complexing agent and total metal ion Bi 3+ 、Na + , Zn 2+ and Ti 4+ The molar ratio is 1.5:1;

[0038] e. Slowly add the mixed solution obtained in step c to the mixed solution obtained in step d, stir while addin...

Embodiment 3

[0044] a. Dissolve bismuth nitrate in ethylene glycol, stir in a water bath at a constant temperature of 55°C until completely dissolved, and prepare a 0.5mol / L alkoxide solution for later use;

[0045] b. Using sodium acetate and zinc acetate with a molar percentage of Na:Zn=1:1 as raw materials, mix and dissolve in absolute ethanol, prepare a 0.5mol / L ion mixed solution, and set aside;

[0046] c. Dissolve tetrabutyl titanate in absolute ethanol to prepare a 1mol / L solution, add acetylacetone dropwise to stabilize tetrabutyl titanate, stir evenly to obtain a mixed solution, and set aside;

[0047] d, the solution that step a obtains is slowly added dropwise in the solution that step b obtains, after mixing uniformly, add citric acid complexing agent, citric acid complexing agent and total metal ion Bi 3+ 、Na + , Zn 2+ and Ti 4+ The molar ratio is 1.5:1;

[0048] e. Slowly add the mixed solution obtained in step c to the mixed solution obtained in step d, stir while addin...

PUM

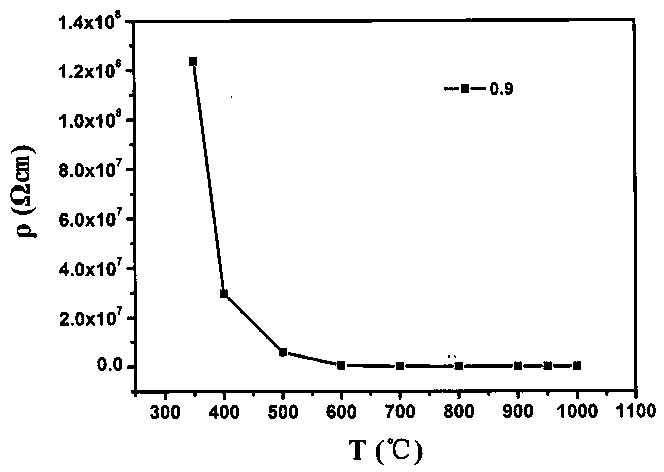

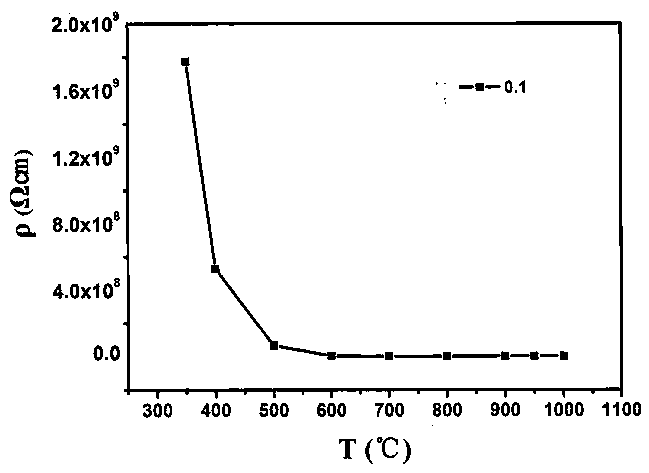

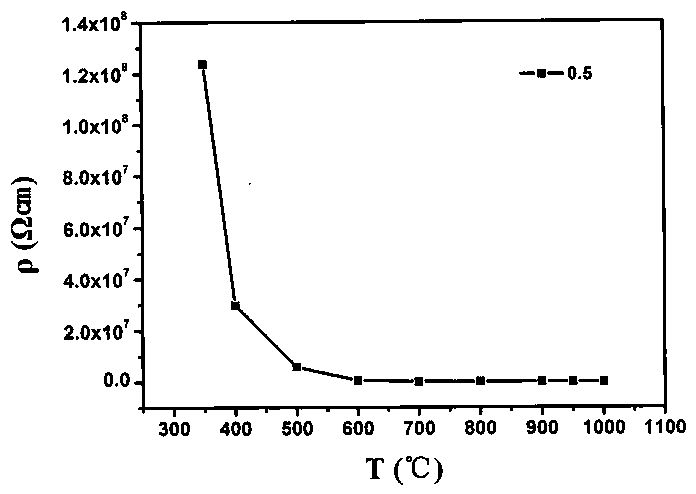

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com