A kind of bismuth titanate-based perovskite phase heat-sensitive ceramic composite material and its preparation method and use

A technology of perovskite phase and heat-sensitive ceramics, applied in circuits, resistors, resistors with negative temperature coefficients, etc., can solve problems such as aging and irreversible changes in temperature resistance characteristics, and achieve high density and small grain size , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

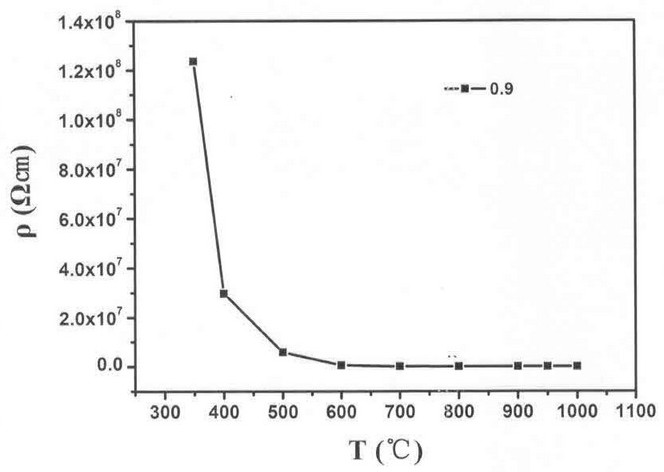

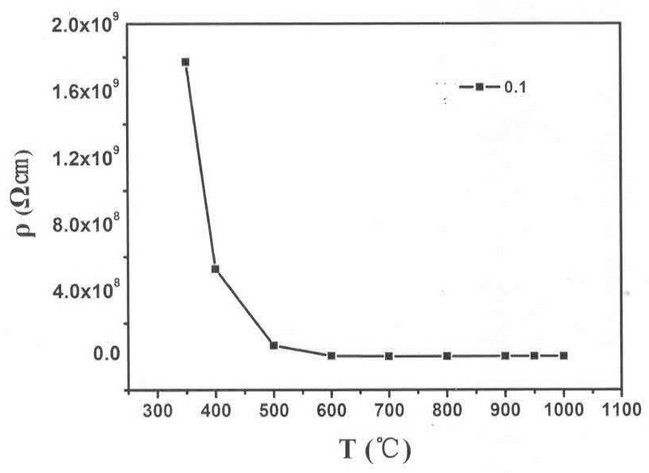

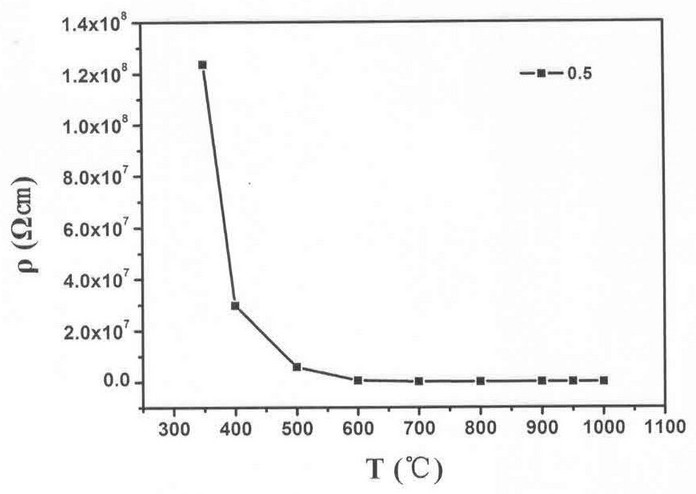

Image

Examples

Embodiment 1

[0024] a. Dissolve bismuth nitrate in ethylene glycol, stir in a water bath at a constant temperature of 40°C until completely dissolved, and prepare a 0.5mol / L alkoxide solution for later use;

[0025] b. Take sodium acetate and zinc acetate with a molar percentage of Na:Zn=9:1 as raw materials, mix and dissolve in absolute ethanol, prepare a 0.5mol / L ion mixed solution, and set aside;

[0026] c. Dissolve tetrabutyl titanate in absolute ethanol to prepare a 1mol / L solution, add acetylacetone dropwise to stabilize tetrabutyl titanate, stir evenly to obtain a mixed solution, and set aside;

[0027] d, the solution obtained in step a is slowly dripped into the solution obtained in step b, after mixing evenly, add citric acid complexing agent, citric acid complexing agent and total metal ion Bi 3+ 、Na + , Zn 2+ and Ti 4+ The molar ratio is 1.5:1;

[0028] e. Slowly add the mixed solution obtained in step c to the mixed solution obtained in step d, stir while adding dropwise,...

Embodiment 2

[0034] a. Dissolve bismuth nitrate in ethylene glycol, stir in a water bath at a constant temperature of 70°C until completely dissolved, and prepare a 0.5mol / L alkoxide solution for later use;

[0035] b. Using sodium acetate and zinc acetate with a molar percentage of Na:Zn=1:9 as raw materials, mix and dissolve in absolute ethanol, prepare a 0.5mol / L ion mixed solution, and set aside;

[0036] c. Dissolve tetrabutyl titanate in absolute ethanol to prepare a 1mol / L solution, add acetylacetone dropwise to stabilize tetrabutyl titanate, stir evenly to obtain a mixed solution, and set aside;

[0037] d, the solution that step a obtains is slowly added dropwise in the solution that step b obtains, after mixing uniformly, add citric acid complexing agent, citric acid complexing agent and total metal ion Bi 3+ 、Na + , Zn 2+ and Ti 4+ The molar ratio is 1.5:1;

[0038] e. Slowly add the mixed solution obtained in step c to the mixed solution obtained in step d, stir while addin...

Embodiment 3

[0044] a. Dissolve bismuth nitrate in ethylene glycol, stir in a water bath at a constant temperature of 55°C until completely dissolved, and prepare a 0.5mol / L alkoxide solution for later use;

[0045] b. Using sodium acetate and zinc acetate with a molar percentage of Na:Zn=1:1 as raw materials, mix and dissolve in absolute ethanol, prepare a 0.5mol / L ion mixed solution, and set aside;

[0046] c. Dissolve tetrabutyl titanate in absolute ethanol to prepare a 1mol / L solution, add acetylacetone dropwise to stabilize tetrabutyl titanate, stir evenly to obtain a mixed solution, and set aside;

[0047] d, the solution that step a obtains is slowly added dropwise in the solution that step b obtains, after mixing uniformly, add citric acid complexing agent, citric acid complexing agent and total metal ion Bi 3+ 、Na + , Zn 2+ and Ti 4+ The molar ratio is 1.5:1;

[0048] e. Slowly add the mixed solution obtained in step c to the mixed solution obtained in step d, stir while addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com