Laser-magnetic field compound melt brazed welding method for aluminum alloy/steel

A welding method and technology of aluminum alloy, applied in welding equipment, welding/welding/cutting items, metal processing, etc., can solve the problems of uneven structure and low connection strength of the joint surface, and achieve the effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

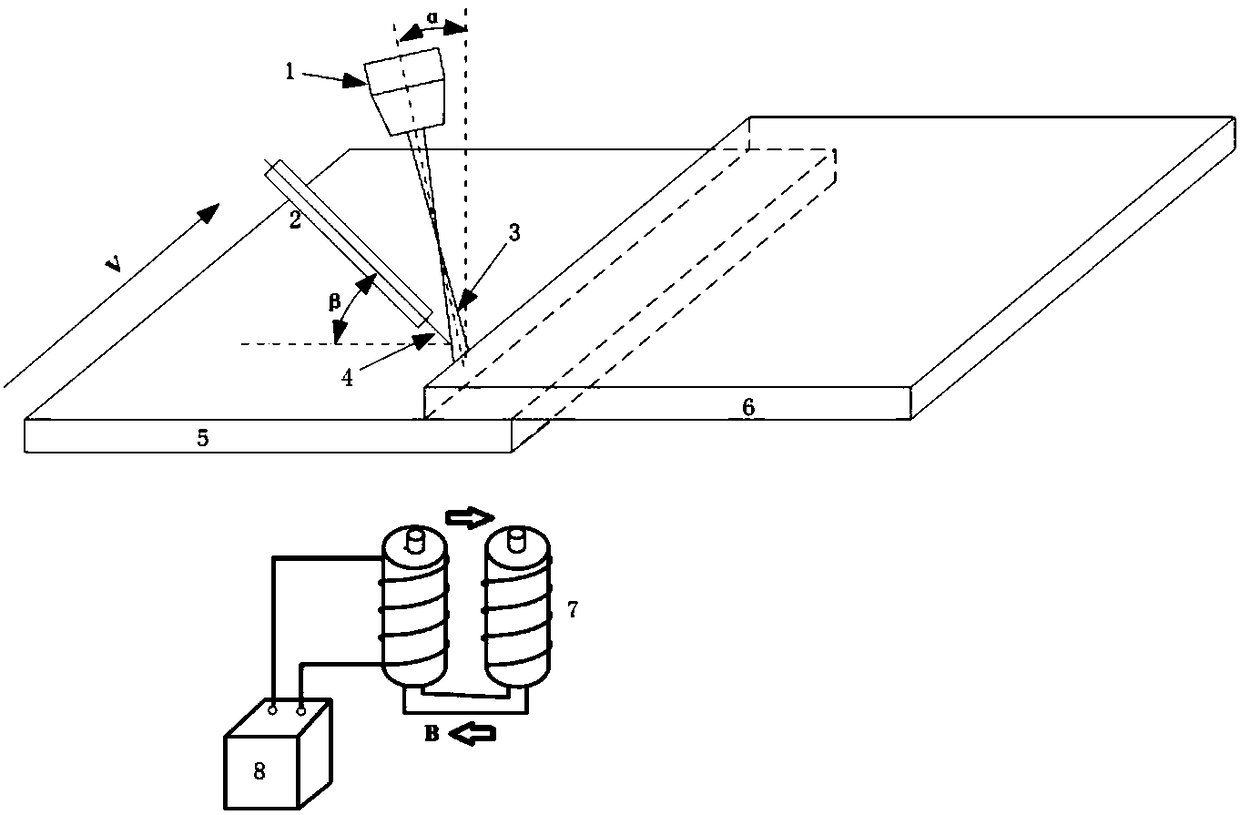

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

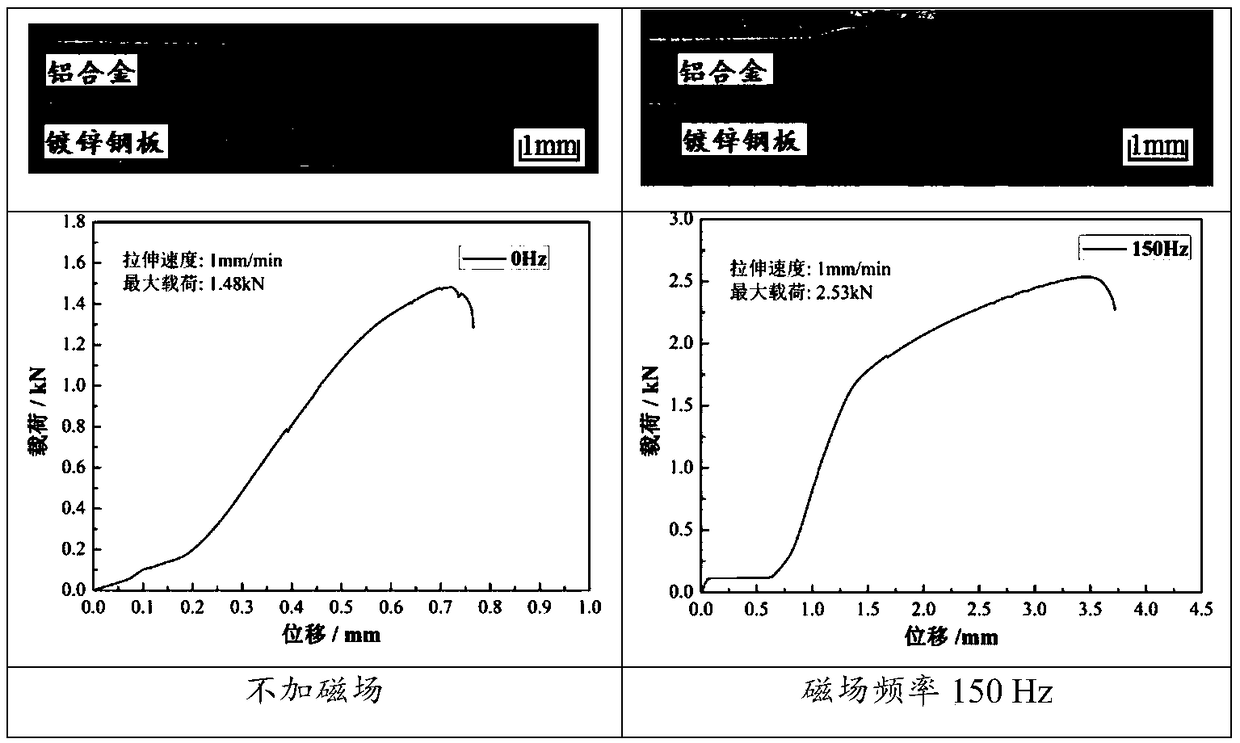

[0033] In view of the above-mentioned technical problems of aluminum alloy / steel laser welding and brazing, such as uneven structure and low connection strength of the joint surface, the present invention provides a method for aluminum alloy / steel laser-magnetic field composite welding and brazing, which includes the following steps:

[0034] S1 cleans and fixes the aluminum alloy and steel plate to be overlapped;

[0035] S2 selects the laser energy according to the required welding thickness, and selects zinc-aluminum alloy or aluminum-silicon alloy welding wire 4 as the filler metal; in the present invention, zinc-aluminum alloy is selected, and the presence of zinc can improve the spreadability and wetting of the liquid metal at the steel-aluminum interface sex.

[0036] S3 controls the wire feeding speed of the welding torch 2 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com