Face-care mask liquid for old people

A facial mask liquid, technology for the elderly, applied in the field of facial care mask liquid for the elderly, to achieve the effects of increasing self-healing ability, film-forming performance, water retention performance, and active performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

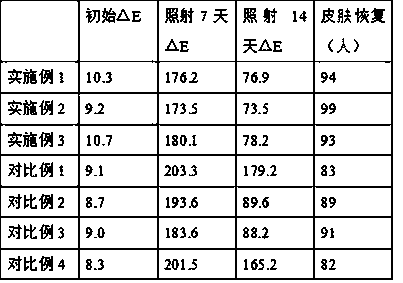

Examples

preparation example Construction

[0021] The preparation of the film-forming mixture is as follows: mix polyglutamic acid and water uniformly in a mass ratio of 6 to 9:20, put them into a reactor, add bromoethane, Maleic acid with 13-15% polyglutamic acid mass and 2-5% polyglutamic acid tetrabutyl titanate, use nitrogen protection, preheat at 60-70°C for 40min, then add polyglutamic acid mass 50-65% triacontanol, heated to 160-170°C, stirred for 8 hours, collected the reaction mixture, evaporated to recover ethyl bromide, filtered, and collected the filtrate to obtain the film-forming mixture.

[0022] The repairing agent is prepared as follows: in parts by weight, 30 to 50 parts of edible fly maggots, 13 to 16 parts of lemons, 11 to 13 parts of gentian, 9 to 12 parts of Baiji, 8 to 10 parts of white poria cocos, 6 ~13 parts of Rosa roxburghii, put into a mill and grind at 400r / min for 30min, collect the ground material, mix and ferment the ground material and lactic acid bacteria powder at a mass ratio of 8~1...

Embodiment 1

[0028] The emulsifier is sodium stearoyl lactylate mixed in a mass ratio of 1:3.

[0029] The dispersant is vinyl bis stearamide.

[0030] The moisturizing agent is formed by mixing aloe vera gel and trimethylglycine at a mass ratio of 7:1.

[0031] The preparation of the film-forming mixture is as follows: mix polyglutamic acid and water evenly in a mass ratio of 6:20, put them into a reactor, add bromoethane and polyglutamic acid with 2% of the mass of polyglutamic acid to the reactor. 13% by mass of maleic acid and 2% by mass of polyglutamic acid tetrabutyl titanate, under nitrogen protection, preheated at 60°C for 40 minutes, then added triacontanol with 50% by mass of polyglutamic acid, and heated up to Stir and react at 160°C for 8 hours, collect the reaction mixture, evaporate and recover ethyl bromide, filter, and collect the filtrate to obtain the film-forming mixture.

[0032] The preparation of the repairing agent is as follows: in parts by weight, take 30 parts o...

Embodiment 2

[0036] The emulsifier is made by mixing sodium stearoyl lactylate and monoglyceride laurate at a mass ratio of 1:4.

[0037] The dispersant is oxidized polyethylene wax.

[0038] The moisturizing agent is formed by mixing aloe vera gel and trimethylglycine at a mass ratio of 7:1.

[0039] The preparation of the film-forming mixture is as follows: mix polyglutamic acid and water evenly in a mass ratio of 8:20, put them into a reactor, add bromoethane and polyglutamic acid with 4% polyglutamic acid mass to the reactor. 14% by mass of maleic acid and 3% by mass of polyglutamic acid tetrabutyl titanate, under nitrogen protection, preheated at 65°C for 40 minutes, then added triacontanol with 58% by mass of polyglutamic acid, and heated up to Stir and react at 165°C for 8 hours, collect the reaction mixture, evaporate and recover ethyl bromide, filter, and collect the filtrate to obtain the film-forming mixture.

[0040]The preparation of the repairing agent is as follows: in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com