Self-odor-removing nail polish and preparation method thereof

A nail polish and formula technology, applied in manicure, pedicure, pharmaceutical formulations, etc., can solve problems such as being harmful to nails and the human body, and that small molecules cannot be naturally volatilized and blocked, and achieve the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of self-cleaning flavor nail polish, comprising the following steps:

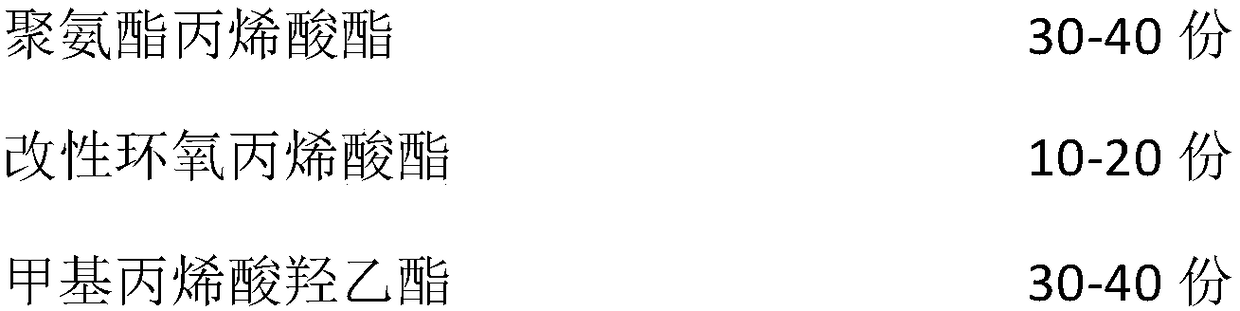

[0029] S1: Put 30 parts of urethane acrylate, 10 parts of modified epoxy acrylate and 30 parts of hydroxyethyl methacrylate into the reaction vessel according to the formula; use FS30 double-shaft frequency conversion speed regulation mixer produced by Dongguan Litengda Intelligent Equipment Co., Ltd. , stirring at a speed of 1000-1500 rpm for 15-30 minutes;

[0030] S2: Add 5 parts of nanoscale tourmaline powder and 5 parts of lanthanide cerium group rare earth; use FS30 dual-axis frequency conversion speed regulation mixer produced by Dongguan Litengda Intelligent Equipment Co., Ltd., stir at 2000-3000 rpm for 30- 60 minutes;

[0031] S3: Add 2 parts of 1-hydroxycyclohexyl phenyl ketone, 2 parts of phenylbis(2,4,6-trimethylbenzoyl) phosphine oxide, 1 part of Degussa R974 fumed silica, 0.1 part of tego920 defoamer and 0.1 part of tego450 leveling agent; stir at a speed of 1000...

Embodiment 2

[0038] A preparation method of self-cleaning flavor nail polish, comprising the following steps:

[0039] S1: Put 40 parts of urethane acrylate, 20 parts of modified epoxy acrylate and 40 parts of hydroxyethyl methacrylate into the reaction vessel according to the formula; use FS30 double-shaft frequency conversion speed regulation mixer produced by Dongguan Litengda Intelligent Equipment Co., Ltd. , stirring at a speed of 1000-1500 rpm for 15-30 minutes;

[0040] S2: Then add 15 parts of nanoscale tourmaline powder and 10 parts of lanthanide cerium group rare earth; use the FS30 dual-axis frequency conversion speed regulation mixer produced by Dongguan Litengda Intelligent Equipment Co., Ltd., and stir at 2000-3000 rpm for 30- 60 minutes;

[0041] S3: add 4 parts of 1-hydroxycyclohexyl phenyl ketone, 10 parts of phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide, 2 parts of Degussa R974 fumed silica, 1 part of tego920 defoamer and 1 part of tego450 leveling agent; stir at a...

Embodiment 3

[0049] A preparation method of self-cleaning flavor nail polish, comprising the following steps:

[0050] S1: Put 35 parts of urethane acrylate, 15 parts of modified epoxy acrylate and 35 parts of hydroxyethyl methacrylate into the reaction vessel according to the formula; use FS30 double-shaft frequency conversion speed regulation mixer produced by Dongguan Litengda Intelligent Equipment Co., Ltd. , stirring at a speed of 1000-1500 rpm for 15-30 minutes;

[0051] S2: Then add 10 parts of nanoscale tourmaline powder and 8 parts of lanthanide cerium group rare earth; use the FS30 dual-axis frequency conversion speed regulation mixer produced by Dongguan Litengda Intelligent Equipment Co., Ltd., and stir at 2000-3000 rpm for 30- 60 minutes;

[0052] S3: Add 3 parts of 1-hydroxycyclohexyl phenyl ketone, 6 parts of phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide, 1.5 parts of Degussa R974 fumed silica, 0.5 parts of tego920 defoamer and 0.5 parts of tego450 leveling agent; sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com