Production device for thermal reaction essence

A heat-reactive essence and production device technology, which is applied in the direction of essential oil/fragrance, chemical/physical/physicochemical fixed reactors, fat production, etc., can solve the problems that are not suitable for the production of clear and transparent heat-reactive essence, and achieve an increase Fragrance strength, solve the effect of weak strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

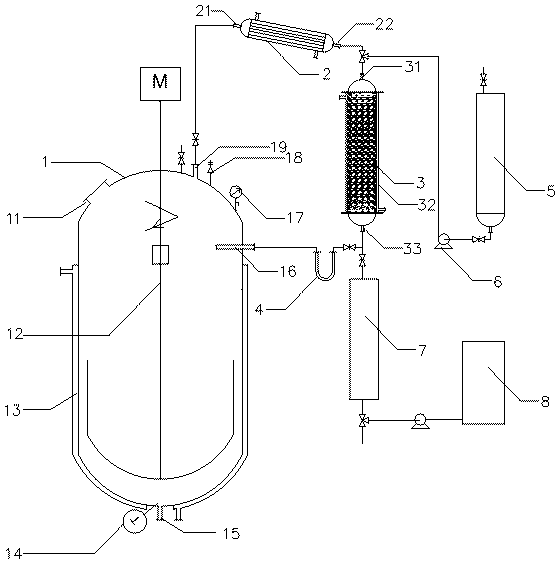

[0016] It is mainly composed of reaction kettle body 1, condenser 2, chromatography column 3, U-shaped tube 4, eluent storage tank 5, constant flow pump 6, buffer tank 7, concentrator 8 and the delivery pipelines between the components The described reactor body 1 is provided with a mixed steam outlet 19 and a return conduit 16; the described condenser 2 is provided with a steam inlet 21 and a condensate outlet 22; the described chromatographic column 3 is provided with a feed Port 31 and discharge port 33; described mixed steam outlet 19 is connected with steam inlet 21 with pipeline, and described condensate outlet 22 is connected with feed port 31 with pipeline, and described discharge port 33 and return conduit 16 U-shaped pipe 4 is connected between them, and the position of the outlet 33 on the chromatographic column 3 is higher than the position of the return conduit 16 on the reactor body 1; the eluent storage tank 5 and the chromatographic The feed port 31 on the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com