An integrated heat exchange structure based on battery modules

A technology of battery module and heat exchange structure, which is applied to secondary batteries, electrochemical generators, circuits, etc., can solve the problem of insufficient heat exchange between the condensation section of the heat pipe and the cooling liquid, large volume of the liquid cooling channel, and increased cooling flow. and other problems, to achieve the effect of compact structure, light system weight, and strong heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, structure of the present invention and specific embodiment are described further:

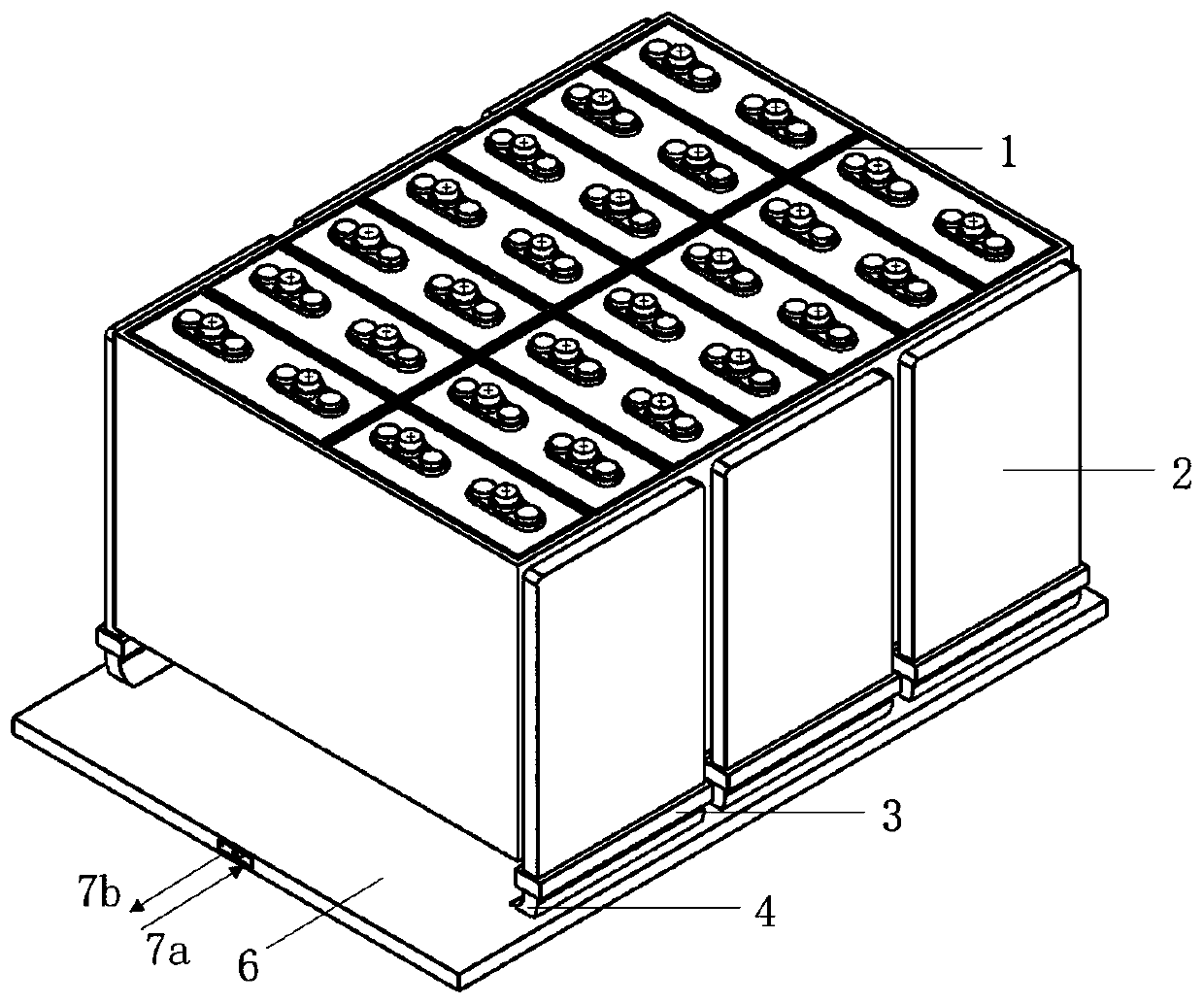

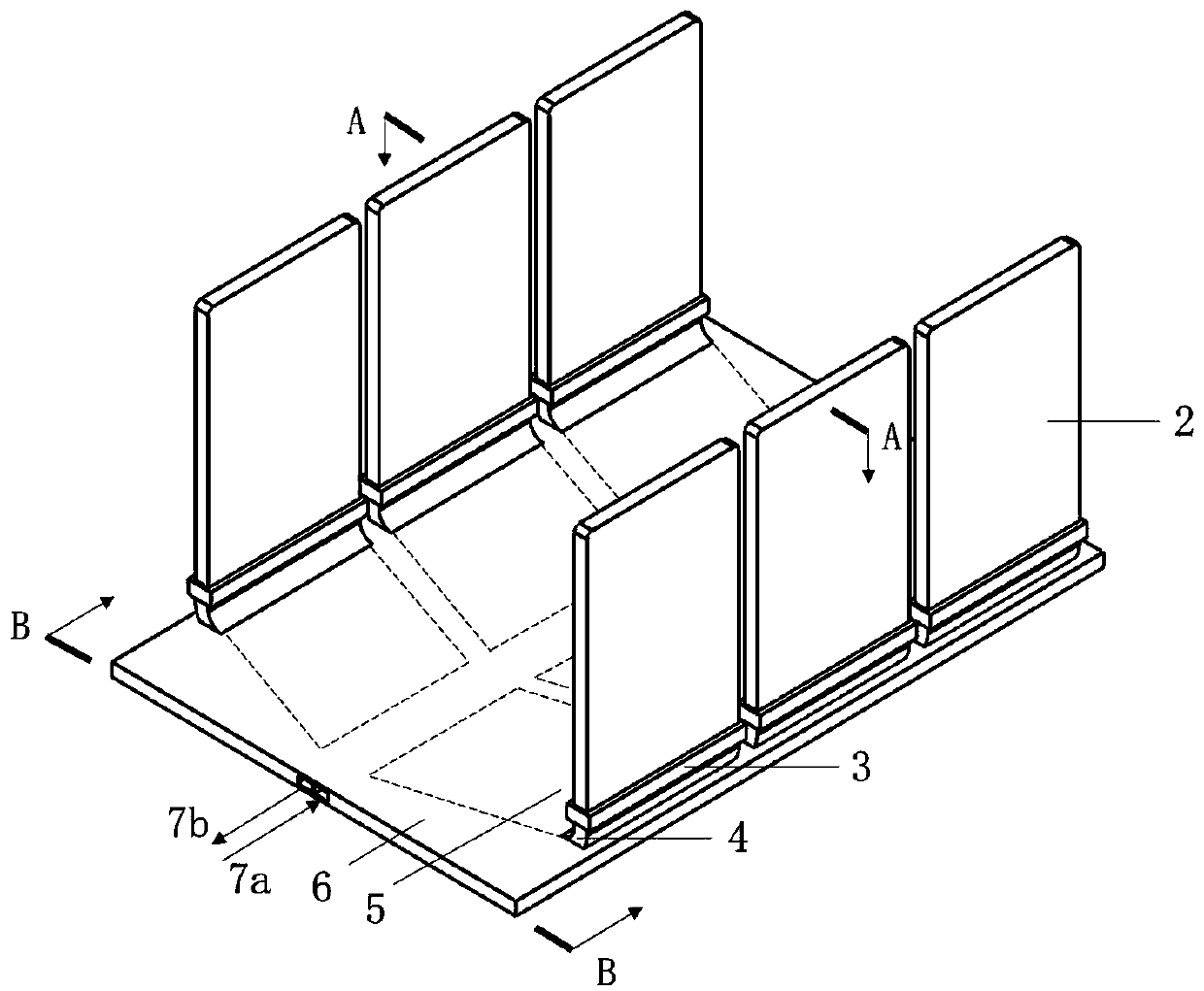

[0021] figure 1 An outline drawing of an integrated heat exchange structure based on a battery module provided by the present invention, the integrated heat exchange structure includes a cold plate 6 and at least one separate flat heat pipe, and the cold plate is arranged under the battery module 1; Each separated flat heat pipe is composed of heat pipe evaporating section 2, heat pipe bending section 4 and heat pipe condensing section 5. Its thickness is as thin as millimeters, and its material is aluminum or copper. Affected by gravity or the inclination of the heat pipe, it has the effect of micro-scale heat transfer enhancement and flat plate temperature uniformity. The separated flat heat pipe can also add a thermal insulation section between the evaporation section and the bending section to meet the long-distance heat conduction req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com