Efficient low-resistance nano-fiber microscopic gradient structure filtering material and preparation method thereof

A technology of micro-nano fiber and gradient structure, applied in the direction of separation method, filtration separation, membrane filter, etc., can solve the problems of low filtration resistance, reduce the porosity of filter material, and not easy to wash, so as to increase the chance of inertial collision and improve the mechanical strength. performance, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Polyvinyl alcohol (M w =2.5×10 5 g / mol) after vacuum drying (50°C, 12h), using deionized water as a solvent, heating up to 80°C and stirring for 2h to obtain a uniform PVA solution with a mass concentration of 10%, and standing for defoaming for 4h.

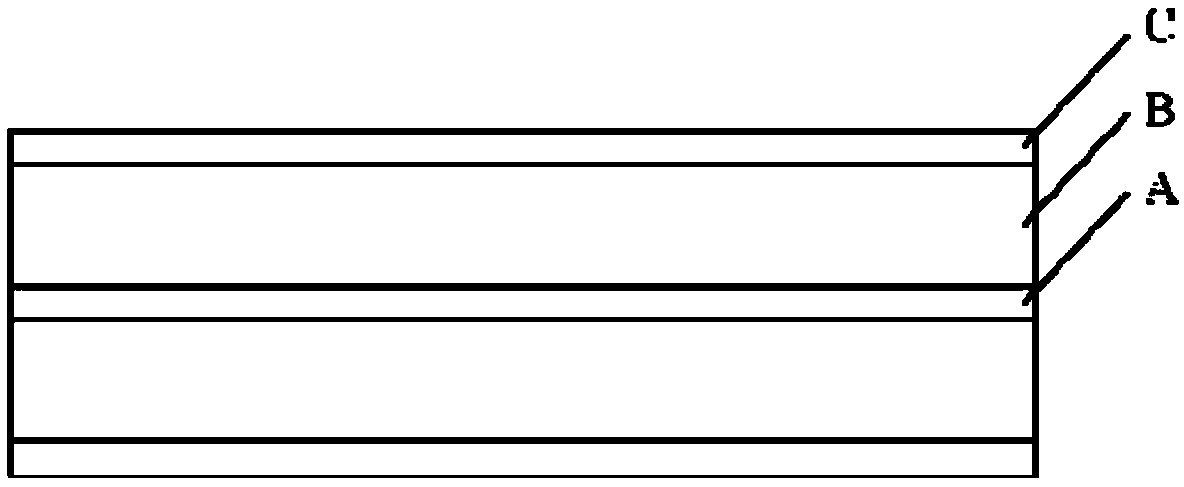

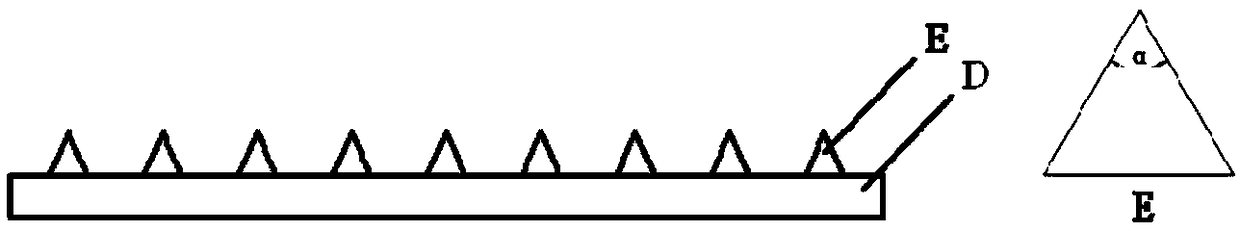

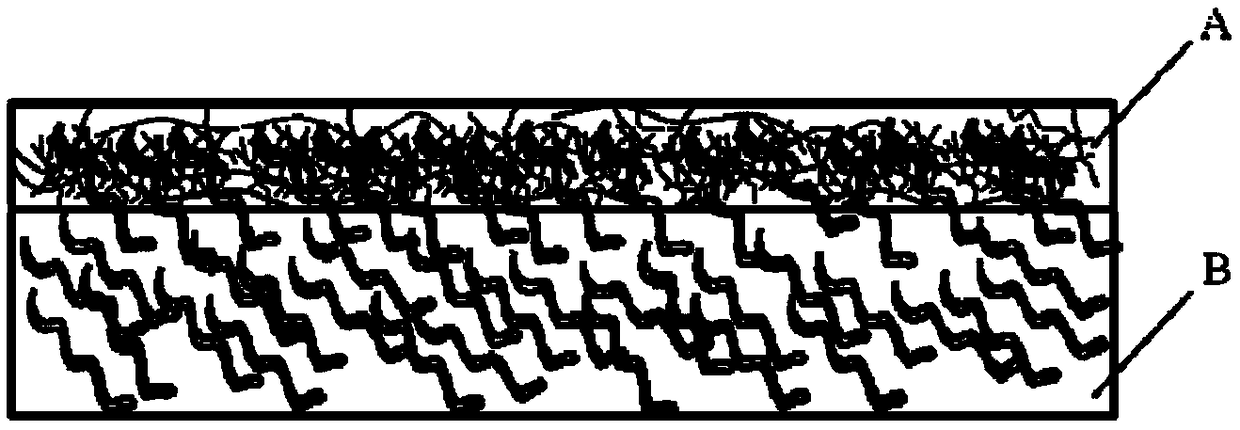

[0062] Such as Figure 1-Figure 3 As shown, the PVA solution is prepared by a needle-free free surface electrospinning method to prepare a nano-fine filter layer A, and the nano-fine filter layer A is a nano-fine filter layer with an uncharged PVA surface. When forming, the distance between the receiving plate and the solution tank is about 25cm, the voltage is about 60kV, and the rotating speed of the rotor in the solution tank that is wrapped with a wire to form a wire electrode is 70r / min. The receiving board is made of plastic, such as Figure 8 As shown, the receiving plate includes a bottom plate and a cone structure. A plurality of cone structures are evenly distributed on the bottom plate. The bottom of the cone...

Embodiment 2

[0069] Polylactic acid (M w =6.0×10 5 g / mol) after vacuum drying (60°C, 10h) for use.

[0070] Such as Figure 1-Figure 3 As shown, the PLA solution is prepared by a melt-blown electrospinning method to prepare a nano-fine filter layer A, and the nano-fine filter layer A is a nano-fine filter layer charged on the surface of PLA. During molding, the distance between the receiving plate and the melt-blown electrostatic spinneret is about 20 cm, the voltage is about 60 kV, and the PLA melt is melt-blown electrospun at a flow rate of 0.3 cc / min. The material of the receiving plate is a stainless steel belt, with a receiving surface structure such as Figure 9 As shown, the receiving surface includes a bottom plate and a cone structure. Multiple cone structures are evenly distributed on the bottom plate. The bottom of the cone structure is a square, the side length F of the square is 1.41mm, and the distribution density of the cone structures is 60. / cm 2 , the height of the t...

Embodiment 3

[0075] Polycaprolactone (M w =1.2×10 6 g / mol) after vacuum drying (50°C, 8h), using dimethylacetamide as a solvent, heating up to 60°C and stirring for 2h to obtain a uniform PCL solution with a mass concentration of 15%, and standing for defoaming for 3h.

[0076] Such as Figure 1-Figure 3 As shown, the PCL solution is prepared by a double-needle electrospinning method to prepare a nano-fine filter layer A, and the nano-fine filter layer A is a charged nano-fine filter layer on the surface of PCL. When forming, the distance between the receiving plate and the needle is about 12cm, the voltage is about 15kV, and the PCL solution is electrospun at a flow rate of 0.5mL / h. The material of the receiving plate is silicon wafer, the receiving plate has a grid diameter of 0.04mm and a density of 80 pieces / cm 2 , a circular grid with a height of 0.02mm. The obtained nano fine filter layer A has a grid structure, and the PCL surface is charged, such as figure 2 As shown, there i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com