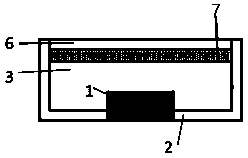

White light LED packaging structure and packaging method

A technology of LED packaging and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency and poor stability of quantum dot white LEDs, and achieve stable visual effects, narrow half-peak width, and good visual effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

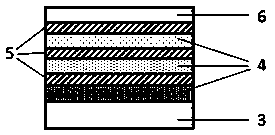

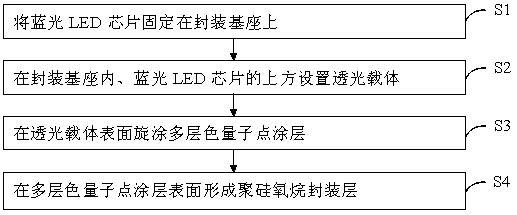

[0045] Fix the blue LED chip on the packaging base, set a light-transmitting carrier in the packaging base and above the blue LED chip; prepare multi-color quantum dots, and use the thermal injection method to synthesize cesium stearate and oleic acid cesium oleate All-inorganic perovskite quantum dots CsPb(Br x I 1-x ) 3 , in which red x=0.42, yellow x=0.6, green x=1, the synthesized quantum dots are centrifuged, using cyclohexane as solvent, solid-liquid ratio is 1:2 (ml / mg), and dispersed by ultrasonic for 10s Dissolve; spin-coat red, yellow, and green quantum dots sequentially on the transparent carrier through vertical layering, absorb 0.01ml of spin-coating on the transparent carrier respectively, the rotation speed is 800rpm, and the number of spin-coating times is 2 times. Atomic layer deposition of alumina is used for isolation and protection. Trimethylaluminum and oxygen are used as raw materials. The power of the equipment is 45W. film. Finally, polysiloxane enc...

Embodiment 2

[0047] Fix the blue LED chip on the packaging base, set a light-transmitting carrier in the packaging base and above the blue LED chip; prepare multi-color quantum dots, and use the thermal injection method to synthesize cesium stearate and oleic acid cesium oleate All-inorganic perovskite quantum dots CsPb(Br x I 1-x ) 3 , where red x=0.45, yellow x=0.58, and green x=1. The synthesized quantum dots were centrifuged, and cyclohexane was used as a solvent with a solid-liquid ratio of 1:1. They were completely dissolved by ultrasonic dispersion for 10 seconds; Layers were spin-coated with red, yellow, and green quantum dots sequentially on the transparent carrier, respectively absorbing 0.01ml of spin coating on the transparent carrier, the rotation speed was 800rpm, and the number of spin coatings was 2 times. For isolation protection, trimethylaluminum and oxygen are used as raw materials, and the power of the equipment is 45W. They are alternately fed into the reaction cham...

Embodiment 3

[0049] Fix the blue LED chip on the packaging base, and set a light-transmitting carrier in the packaging base and above the blue LED chip; prepare multi-color quantum dots and use cesium stearate and oleic acid to synthesize cesium oleate quickly Injected into a mixed solution of oleic acid, oleylamine, lead bromide (or lead iodide), and octadecene to synthesize all-inorganic perovskite quantum dots CsPb(Br x I 1-x ) 3 , where red x=0.42, yellow x=0.6, green x=1, the synthesized quantum dots were centrifuged, and cyclohexane was used as solvent with a solid-liquid ratio of 1:2, and they were completely dissolved by ultrasonic dispersion for 10s; The red, yellow, and green quantum dots were sequentially spin-coated on the transparent carrier, and 0.01ml of the spin-coating was absorbed on the transparent carrier, the rotation speed was 700rpm, and the number of spin-coating times was 3 times. For isolation protection, trimethylaluminum and oxygen are used as raw materials, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com