Quantum dot with high blue light absorption rate and preparation method of quantum dot

A quantum dot and absorptivity technology, applied in the field of quantum dots and their preparation, can solve the problems of increased manufacturing cost of backlight module thickness control difficulty, low blue light absorption rate, increased thickness, etc., and achieves reduced energy consumption and high blue light absorption rate. , the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

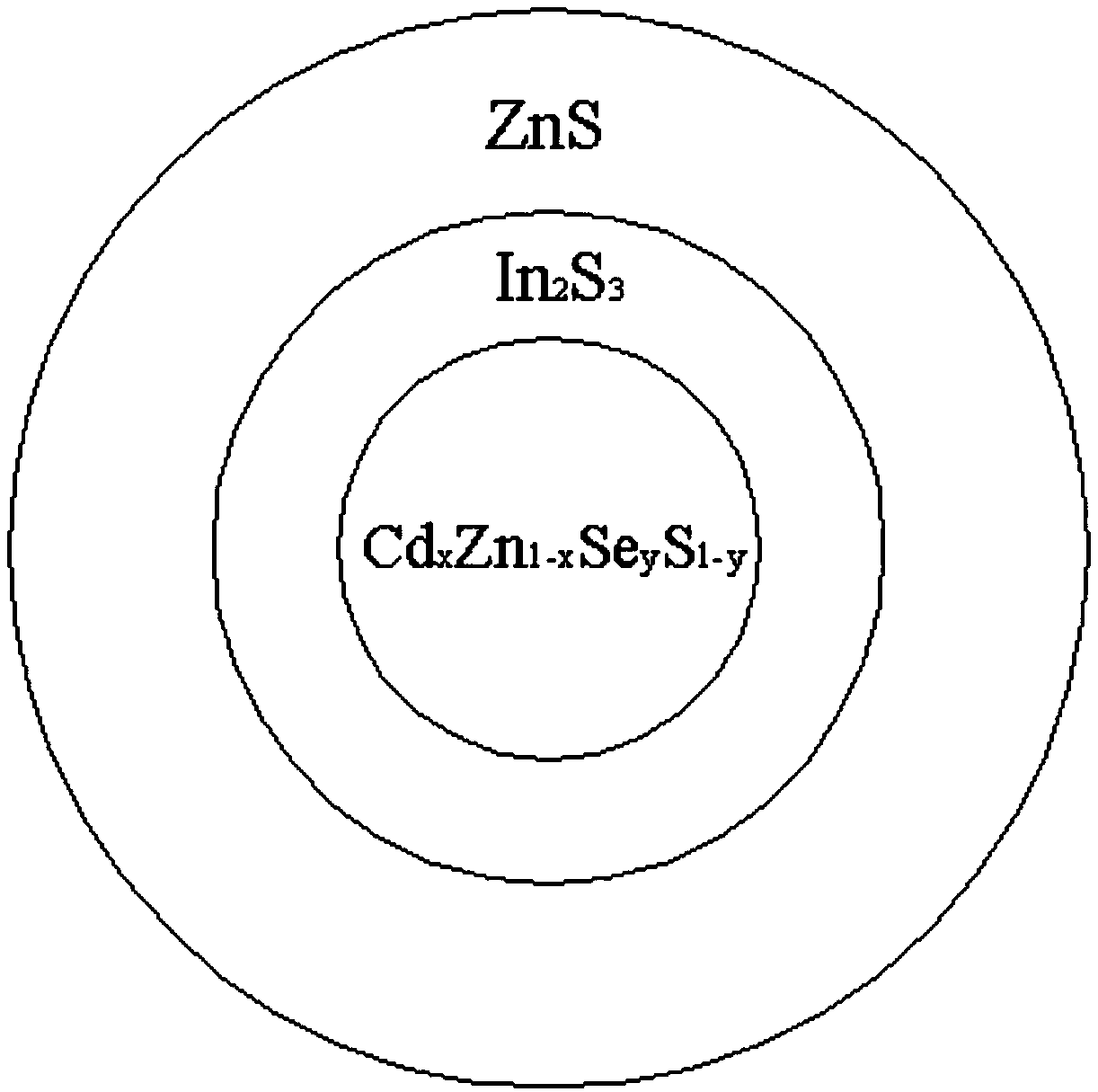

[0031] The embodiment of the present invention also provides a preparation method of quantum dots with high blue light absorption rate, including:

[0032] providing a core composed of CdZnSeS;

[0033] The core is coated with a first shell layer and a second shell layer in sequence, and the material of the first shell layer is In 2 S 3 , the material of the second shell layer is ZnS.

[0034] In some embodiments, the following steps are included:

[0035] (1) Preparation of CdZnSeS core;

[0036] (2) React the mixed reaction system containing CdZnSeS core, indium source and sulfur source at 240-300°C, and grow In on the core 2 S 3 Shell;

[0037] (3) in 2 S 3 After the growth of the shell layer, the precursor containing zinc source and sulfur source is added to the mixed reaction system, and In is grown on the surface. 2 S 3 The ZnS shell is grown on the core of the shell to obtain CdZnSeS / In 2 S 3 / Reaction solution of quantum dots with ZnS structure.

[0038] W...

Embodiment 1

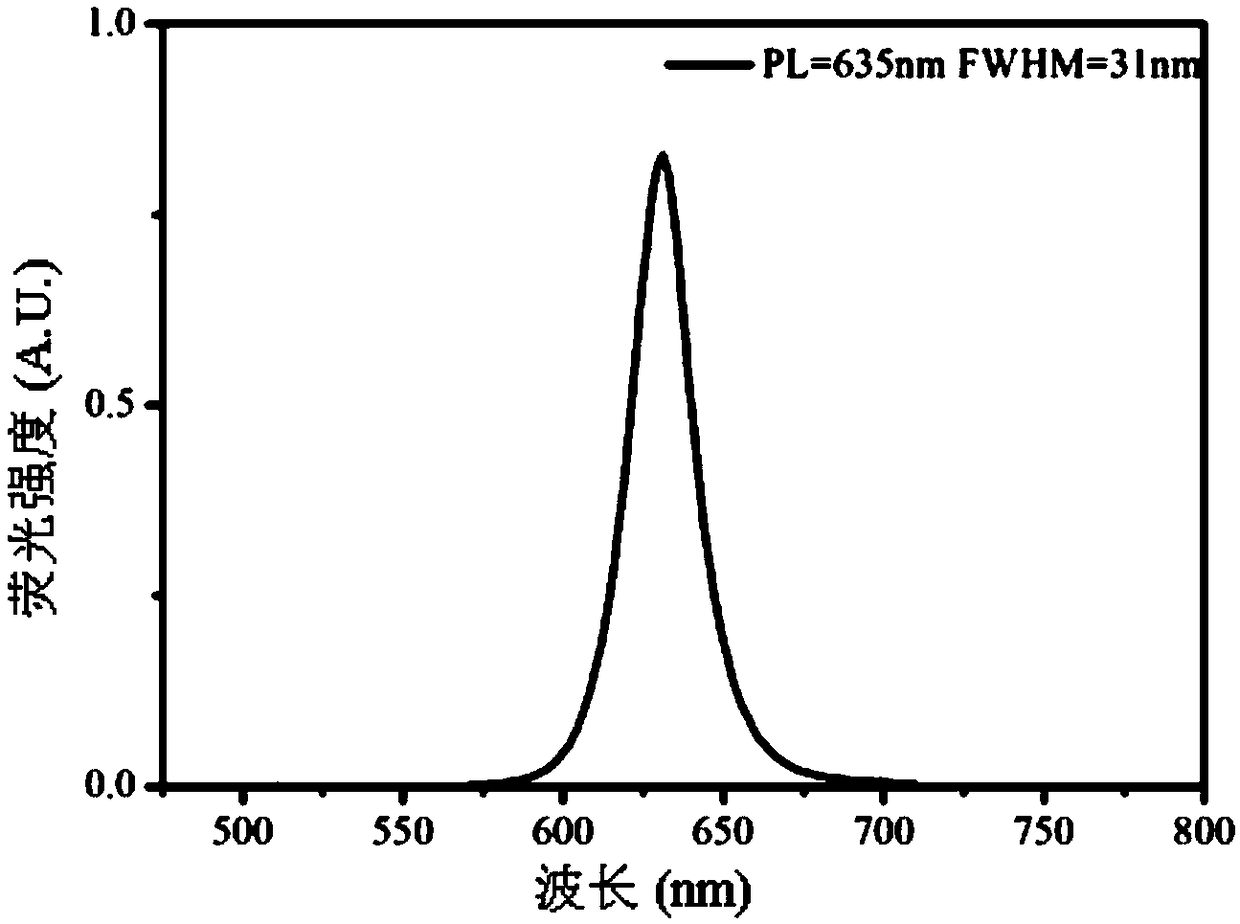

[0100] Red CdZnSeS / In 2 S 3 / ZnS synthesis: take 5ml Cd(OA) 2 with 30ml Zn(OA) 2 , 20ml of 1-octadecene, 10ml of oleic acid, 0.5g of trioctyl phosphine oxide were placed in a 250ml four-neck flask, vacuumed at 100°C until there were no bubbles, filled with argon, heated to 290°C, and injected quickly after reaching the temperature 2.2ml TBP / Se and TBP / S mixture, keep warm for a period of time, adjust the keep time according to the emission wavelength of the product, cool down the reaction system to 260°C after reaching the required wavelength, add 5ml 0.2M TBP / S dropwise with a syringe pump In and 6.7ml 0.3M S / OLAM precursor, react for 90min, and wrap In 2 S 3 Finally, raise the reaction temperature to 280°C, add 20ml of zinc stearate solution and 15ml of S / OLAM precursor dropwise with a syringe pump, add ethanol to purify after the reaction is completed, and disperse the obtained quantum dots into organic solvents such as chloroform .

[0101] The emission spectrum of t...

Embodiment 2

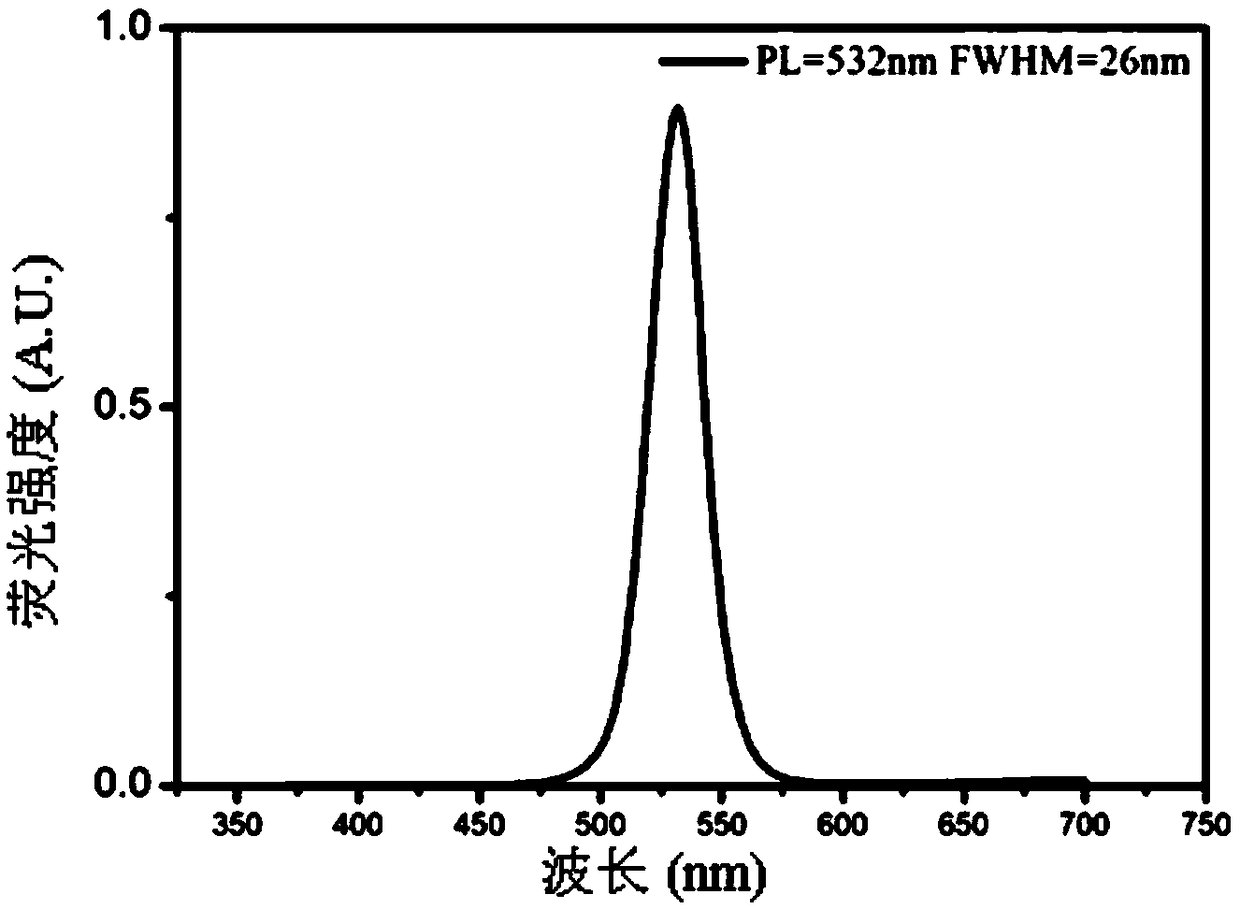

[0103] Green CdZnSeS / In 2 S 3 / ZnS synthesis: take 5ml Cd(OA) 2 with 32ml Zn(OA) 2 , 15ml of 1-octadecene, 10ml of oleic acid, and 0.8g of trioctyl phosphine oxide were placed in a 250ml four-neck flask, vacuumed at 100°C until there were no bubbles, filled with argon, heated to 300°C, and injected quickly after reaching the temperature 3.5ml TBP / Se and TBP / S mixed solution, keep warm for a period of time, the keep time should be adjusted according to the emission wavelength of the product, after reaching the required wavelength, adjust the temperature of the reaction system to 300°C, and add 8m1 0.2M TBP dropwise with a syringe pump / In and 3.6ml 1M TBP / S, react for 5min, wrap In 2 S 3 Finally, raise the reaction temperature to 280°C, and add 20ml of zinc chloride-oleylamine solution and 18ml of S / OLAM solution dropwise with a syringe pump. After the reaction is completed, add ethanol for purification, and the obtained quantum dots are dispersed in organic solvents such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com