Cadmium telluride quantum dots and preparation method thereof

A technology of cadmium telluride quantum dots and cadmium salts, which is applied in the direction of binary selenium/telluride compounds, metal selenide/telluride, nanotechnology, etc., which can solve the problems of good fluorescence performance, difficult merger and preparation time of cadmium telluride quantum dots, etc. problem, to achieve the effect of high fluorescence quantum yield, easy control of reaction conditions, and increase of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

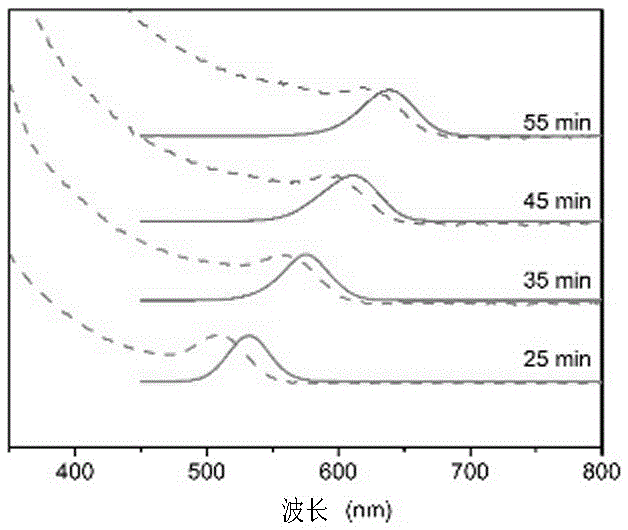

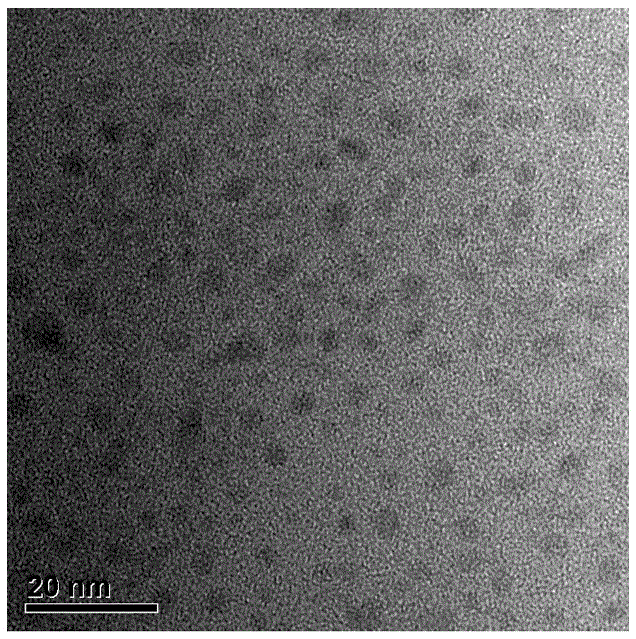

[0028] The invention provides a preparation method of cadmium telluride quantum dots, comprising the following steps: A) mixing tellurium simple substance, borohydride and water under anaerobic conditions, and reacting to obtain a tellurium precursor solution; B) mixing mercapto Compound, soluble cadmium salt, water and alkaline medium are mixed, react to obtain cadmium precursor solution; C) under anaerobic environment and stirring condition, step A) the tellurium precursor solution obtained and step B) the cadmium precursor obtained The solutions are mixed and reacted to obtain a cadmium telluride precursor solution; D) adding the cadmium telluride precursor solution obtained in step C) into a reaction kettle for reaction to obtain cadmium telluride quantum dots.

[0029] In the present invention, the tellurium element is preferably tellurium powder, and the borohydride is one or more of sodium borohydride or potassium borohydride, preferably sodium borohydride. The above-me...

Embodiment 1

[0038] A) Measure 50.8mg of tellurium powder and 37.8mg of sodium borohydride, put them into a 25ml double-necked flask respectively, seal the bottle mouth with an inversion stopper, remove the air in the double-necked flask and fill it with nitrogen protection, inject 10ml of Ultrapure water was heated at 60°C for 20 minutes to obtain a sodium telluride hydride solution.

[0039]B) Measure 45.7mg of cadmium chloride into a flask, add 100mL of water to dissolve, add 17.5μL of thioglycolic acid with a concentration of 2.4mol / mL under stirring, and then add sodium hydroxide solution dropwise to adjust the pH to 9 to obtain a cadmium precursor solution.

[0040] C) Take 1 mL of sodium telluride hydride solution, inject it into 100 mL of cadmium precursor solution under the protection of vigorous stirring and nitrogen flow, and obtain the cadmium telluride precursor solution. Wherein, the molar ratio of Cd / Te / mercaptoacetic acid contained in the system is 1:0.2:1.2.

[0041] D) ...

Embodiment 2

[0045] A) Measure 50.8mg of tellurium powder and 37.8mg of sodium borohydride, put them into a 25ml two-necked flask respectively, seal the bottle mouth with an inversion stopper, remove the air in the two-necked flask and fill it with nitrogen protection, inject 10ml of Ultrapure water was heated at 70°C for 30 minutes to obtain a sodium telluride hydride solution.

[0046] B) Measure 45.7 mg of cadmium chloride and transfer it to a flask, add 100 mL of water to dissolve, add 16 μL of thioglycolic acid with a concentration of 2.4 mol / mL under stirring, and then add 1 M potassium hydroxide solution dropwise to adjust the pH to 8 to obtain a cadmium precursor solution.

[0047] C) Take 2.5 mL of sodium hydride telluride solution, inject it into 100 mL of cadmium precursor solution under the protection of vigorous stirring and nitrogen flow, and obtain the cadmium telluride precursor solution. Wherein, the molar ratio of Cd / Te / mercaptoacetic acid contained in the system is 1:0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com