High-temperature-resistant and multi-principal-phase high-abundance rare-earth permanent magnet material and preparation method thereof

A rare earth permanent magnet, multi-main phase technology, applied in the fields of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of insignificant improvement in magnetic performance, loss of price advantage, increase in raw material cost, etc. Demagnetization ability, lower temperature coefficient of coercivity, lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

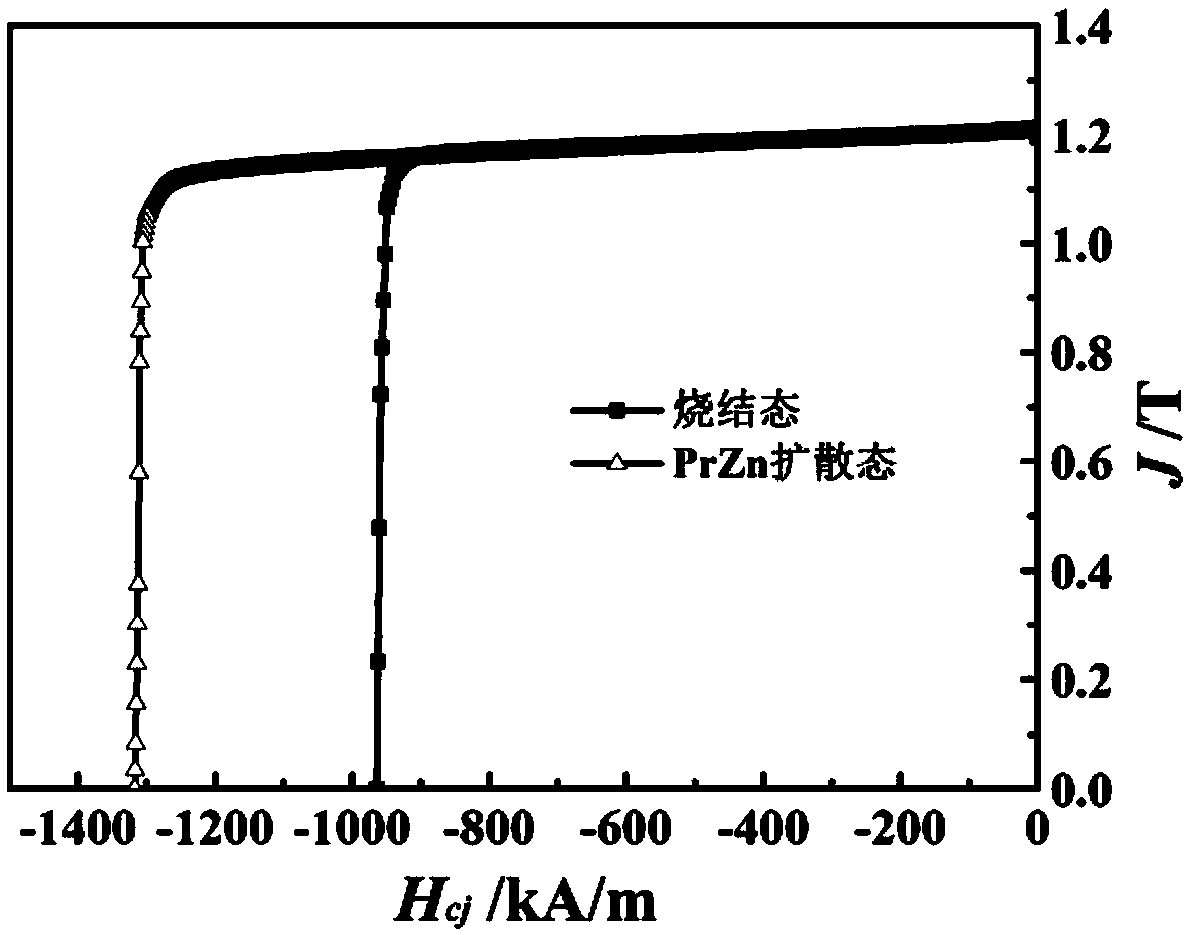

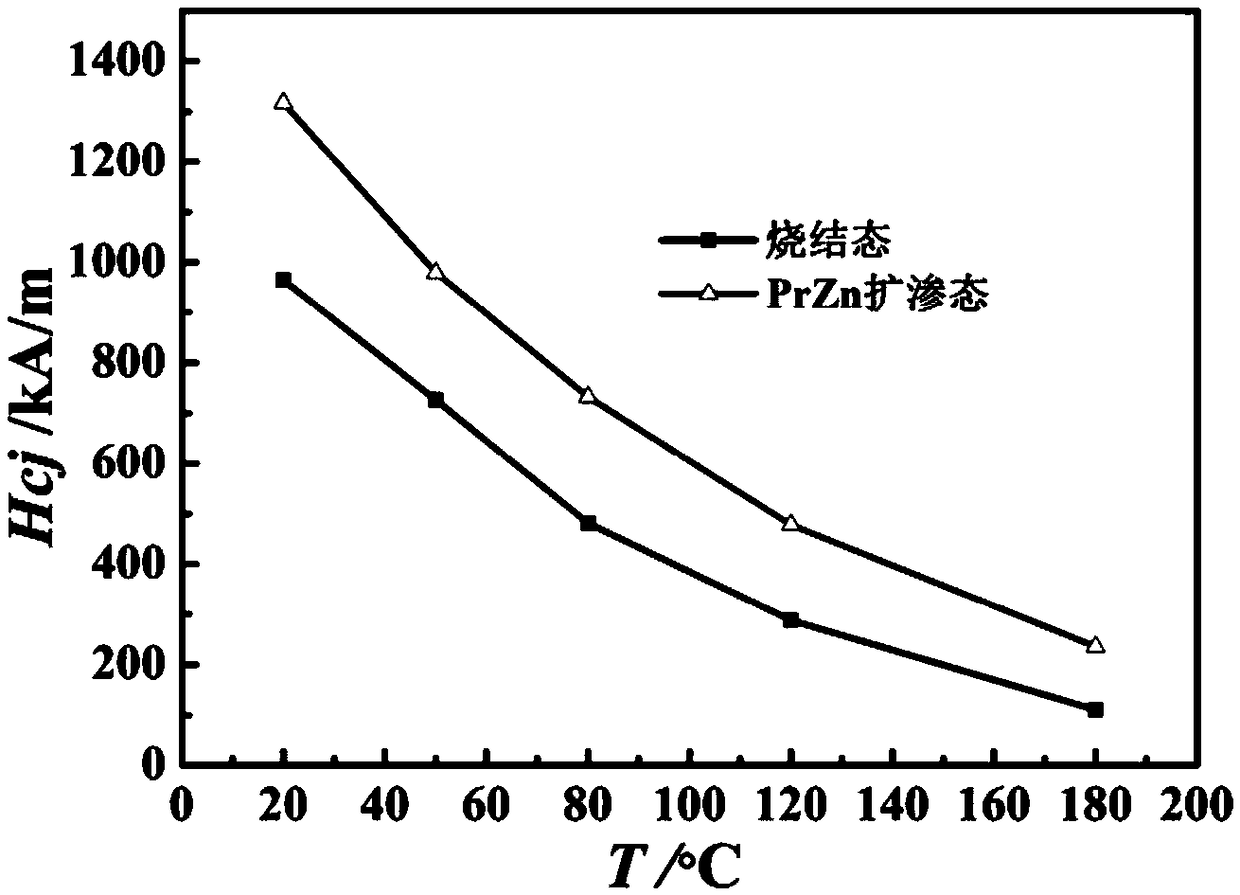

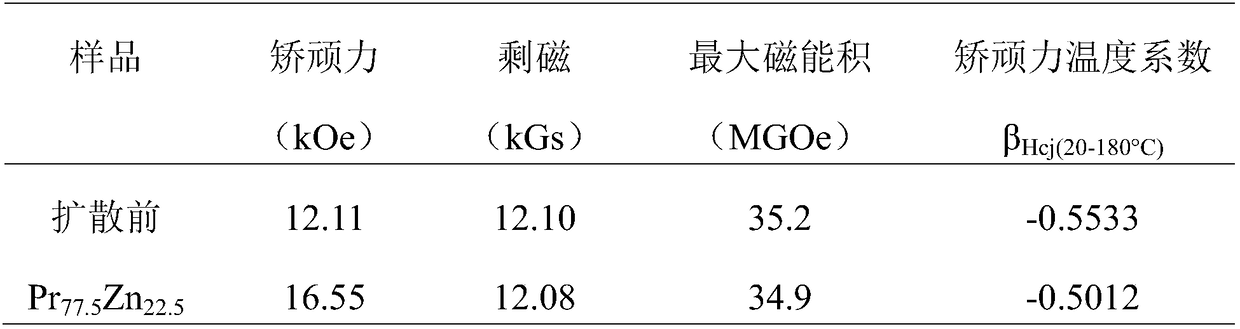

[0043] The N35 sintered cerium-iron-boron permanent magnet (cerium accounts for 30% of the total rare earth content) prepared by the multi-main phase process is machined into 10×10×5mm 3 For samples of different sizes, the surface of the sample was polished and polished, washed with alkali, deionized water, and alcohol ultrasonic vibration for more than 20 minutes, and dried for use; commercially available or self-made Pr 77.5 Zn 22.5 Alloy circular target, the diffusion source material is deposited on the surface of the sample by high temperature magnetron sputtering technology, the specific parameters are: sputtering power is 150W, sputtering pressure is 1.0Pa, background vacuum is better than 3×10 -3 Pa, argon gas flow rate 40sccm, substrate stage temperature 600°C, sputtering time 3h; the sample after high temperature deposition was vacuum heat treated at 500°C for 2h, and the coercive force was significantly improved after air cooling to room temperature. Cerium iron bor...

Embodiment 2

[0047] The N38 sintered cerium-iron-boron permanent magnet (cerium accounts for 20% of the total rare earth content) prepared by the multi-main phase process is machined into 10×10×5mm 3 For samples of different sizes, the surface of the sample was polished and polished, washed with alkali, deionized water, and alcohol ultrasonic vibration for more than 20 minutes, and dried for use; commercially available or self-made Pr 70 Cu 15 Ga 15 Alloy circular target, the diffusion source material is deposited on the surface of the sample by high temperature magnetron sputtering technology, the specific parameters are: sputtering power 120W, sputtering pressure 0.9Pa, background vacuum degree is better than 3×10 -3 Pa, argon gas flow rate 40sccm, substrate stage temperature 500°C, sputtering time 4h; the sample after high temperature deposition was vacuum heat treated at tempering temperature 520°C for 4h, and the coercive force was significantly improved after air cooling to room tem...

Embodiment 3

[0051] The N28 sintered cerium-iron-boron permanent magnet (cerium accounts for 50% of the total rare earth content) prepared by the multi-main phase process is machined into 10×10×5mm 3 For samples of different sizes, the surface of the sample was polished and polished, washed with alkali, deionized water, and alcohol ultrasonic vibration for more than 20 minutes, and dried for use; the prepared ingredients were Ho 70 Cu 30 The alloy raw material is put into a vacuum arc melting furnace or an induction melting furnace, and is repeatedly smelted 5 times under the protection of an inert gas, so that the ingot is fully alloyed, and an alloy ingot is obtained after cooling; the obtained alloy ingot is roughly crushed and placed into the quartz tube of the vacuum quenching furnace, and under the protection of the argon atmosphere, the melt is rapidly quenched under the condition of a roll speed of 8m / s to obtain the required rapid quenching strip; the obtained rapid quenching stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com