Antibacterial non-woven fabric and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

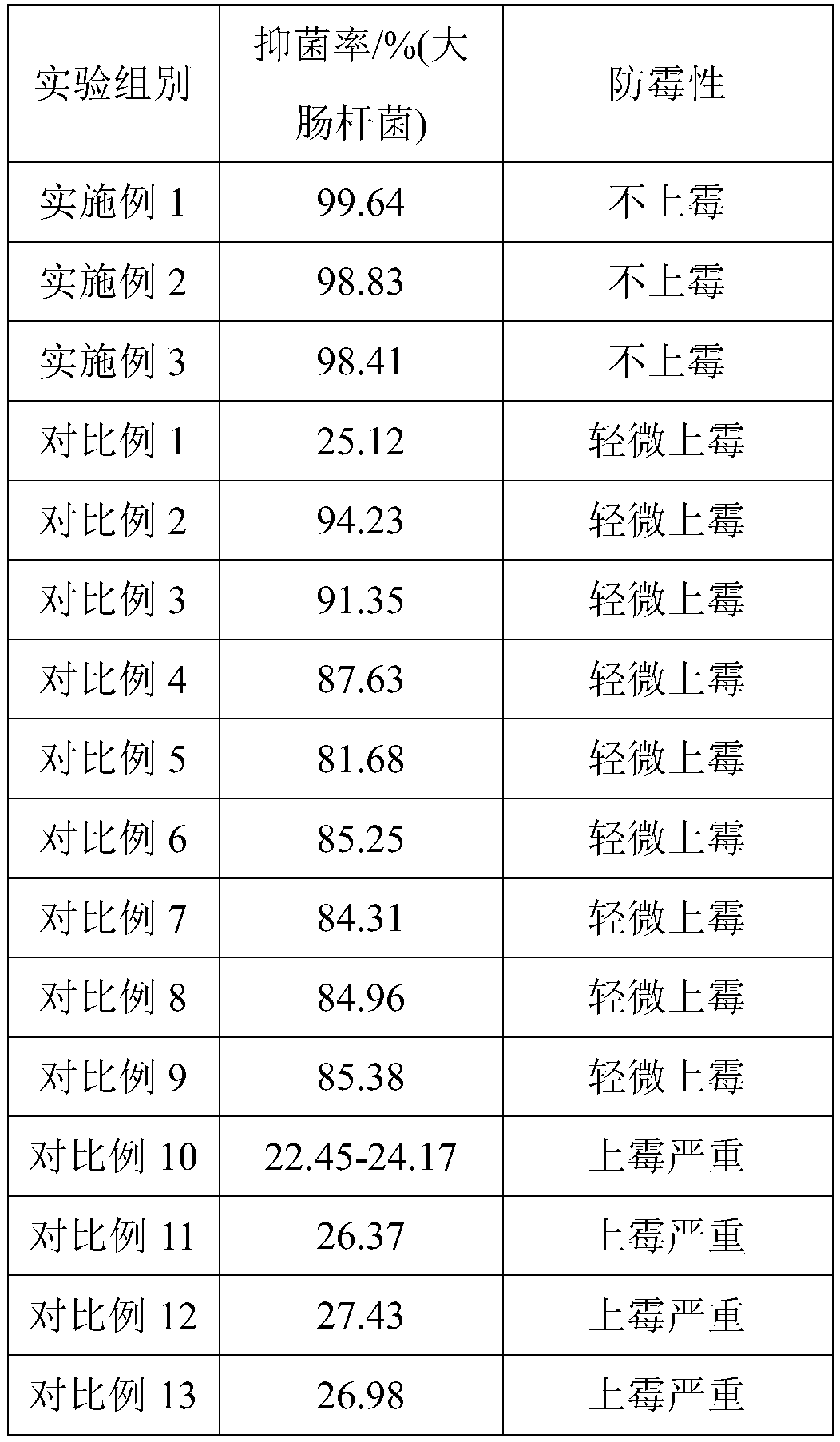

Examples

preparation example Construction

[0027] The preparation method of described antibacterial nonwoven fabric, comprises the following steps:

[0028] S1. Mix polypropylene, nano-silver ion, n-butanol, polyvinylpyrrolidone, ethoxylated alkylamide, n-butanol, polyvinylpyrrolidone and ethoxylated alkylamine, and then add nano-silver Mix the ions evenly, heat up to 60-70°C, keep warm for 1-2h, stir at 650-850r / min for 1-2h, cool to room temperature to obtain the base material;

[0029] S2. Heat the base material to 52-58°C, then add nano-zinc borate, palygorskite, bamboo fiber, inorganic germanium powder and polyethylene terephthalate and mix evenly, heat up to 60-70°C, and keep warm for 1 -3h, keep stirring during the heat preservation process, then add anti-mildew modified filler, anti-bacterial modified additive and silane coupling agent KH-570 and mix evenly, continue to heat up to 80-90°C, at 650-850r / min Stir and disperse for 1-2 minutes to obtain the modified material;

[0030] S3, winding the bamboo fiber ...

Embodiment 1

[0036] An antibacterial non-woven fabric, in parts by weight, comprising the following raw materials: 12 parts of glass fibers, 20 parts of polypropylene, 6 parts of graphene, 4.5 parts of copper oxide, 2.5 parts of nano-silver ions, 4 parts of n-butanol, poly 4 parts of vinylpyrrolidone, 2.5 parts of ethoxylated alkyl acid amine, 11 parts of nano-zinc borate, 3.5 parts of palygorskite, 6 parts of bamboo fiber, 2 parts of inorganic germanium powder, 5 parts of polyethylene terephthalate , 20 parts of anti-mildew modified filler, 15 parts of antibacterial modified auxiliary agent, 2 parts of silane coupling agent KH-570.

[0037] The antibacterial modified auxiliary agent is prepared according to the following process: by weight, 30 parts of montmorillonite, 4.5 parts of hydroxyethyl cellulose, 6 parts of attapulgite and 4.5 parts of mass fraction are mixed with 28% sodium chloride solution Evenly, heat up to 70°C, keep warm for 15min, then stir at 750r / min for 1.5h, filter and...

Embodiment 2

[0047] An antibacterial non-woven fabric, in parts by weight, comprising the following raw materials: 8 parts of glass fiber, 25 parts of polypropylene, 4 parts of graphene, 6 parts of copper oxide, 1 part of nano-silver ion, 5 parts of n-butanol, poly 2 parts of vinylpyrrolidone, 4 parts of ethoxylated alkyl acid amine, 8 parts of nano zinc borate, 5 parts of palygorskite, 4 parts of bamboo fiber, 3 parts of inorganic germanium powder, 4 parts of polyethylene terephthalate , 25 parts of anti-mildew modified filler, 10 parts of antibacterial modified additive, 3 parts of silane coupling agent KH-570.

[0048] The antibacterial modified auxiliary agent is prepared according to the following process: by weight, 20 parts of montmorillonite, 6 parts of hydroxyethyl cellulose, 4 parts of attapulgite and 6 parts of sodium chloride solution with a mass fraction of 18% are mixed Evenly, heat up to 80°C, keep it warm for 10min, then stir at 850r / min for 1h, filter and dehydrate, dry at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com