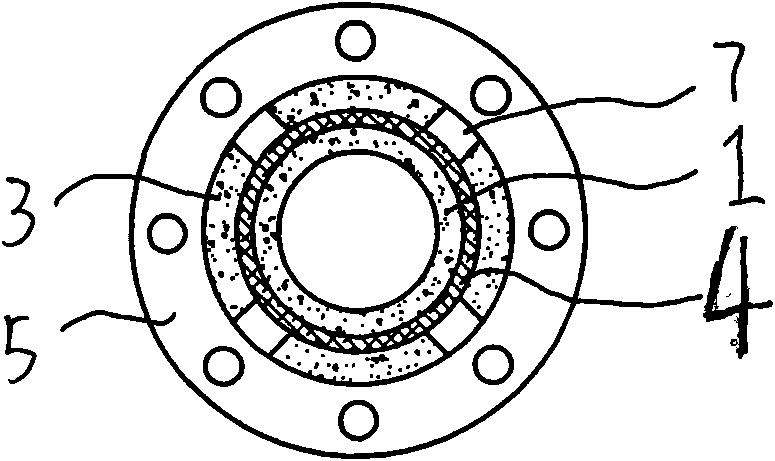

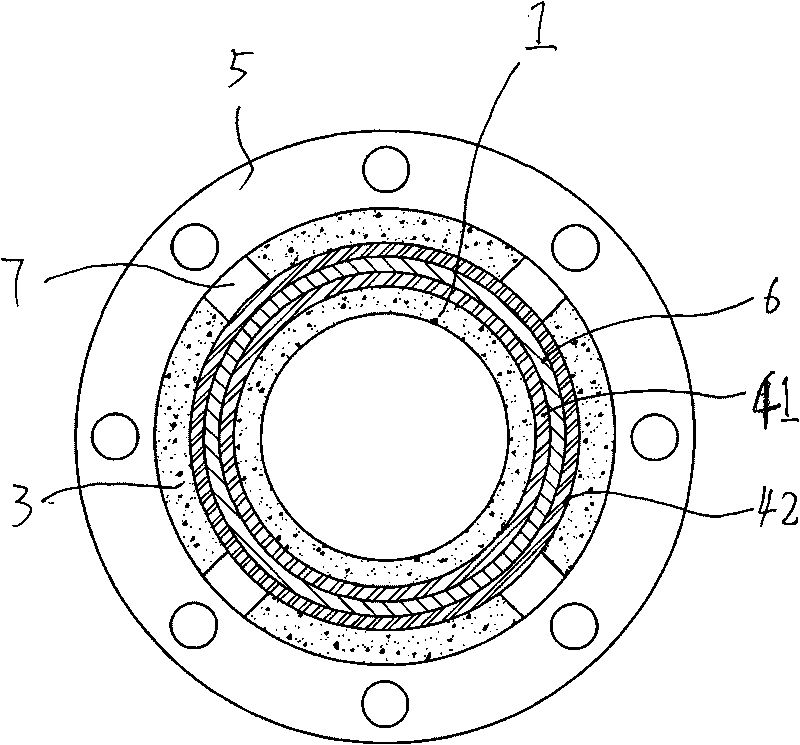

Over-pressure over-temperature environment-friendly silica gel composite pipe and preparation method thereof

A technology for composite pipes and manufacturing methods, which is applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of high cost, reduced production efficiency, and low strength, and achieve the effects of improving strength, preventing bulging, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The first step is to prepare the inner rubber layer

[0054] 1a. Extrude the original inner rubber layer

[0055] Weigh silicone rubber SR: 100 kg, fumed silica: 40 kg, vulcanizing agent bis-25DBPMH: 0.4 kg, ferric oxide: 1 kg, environmentally friendly and odorless adhesive AS-88: 5 kg, inorganic flame retardant 5 kg of aluminum hydroxide is used for mixing, and then a soft core tire mandrel is selected, and the original inner rubber layer is extruded through a silicone rubber extruder, and the temperature of the fuselage head is controlled at 20°C;

[0056] 1b. Frozen molding

[0057]Control the temperature in the freezing chamber of the freezing equipment at -35°C, and then input the extruded original inner rubber layer into the pipe sleeve located in the cooling chamber for 18 minutes to obtain the formed inner rubber layer;

[0058] The second step is to wind the reinforcement layer

[0059] Weaving and winding methods are adopted on the outside of the freeze-for...

Embodiment 2

[0069] The first step is to prepare the inner rubber layer

[0070] 1a. Extrude the original inner rubber layer

[0071] Weigh silicone rubber SR: 100 kg, fumed silica: 55 kg, vulcanizing agent bis-25DBPMH: 1 kg, ferric oxide: 5 kg, coloring agent: 5 kg, environmentally friendly and odorless adhesive AS-88: 8 kg, 8 kg of inorganic flame retardant aluminum hydroxide for mixing, then select a soft core tire mandrel, extrude the original inner rubber layer through a silicone rubber extruder, and control the temperature of the machine head at 40 °C;

[0072] 1b. Frozen molding

[0073] The temperature in the freezing chamber of the freezing equipment is controlled at -45°C, and then the extruded original inner rubber layer is input into the pipe sleeve located in the cooling chamber for 12 minutes of freezing to obtain the formed inner rubber layer;

[0074] The second step is to wind the reinforcement layer

[0075] Weaving and winding methods are adopted on the outside of the...

Embodiment 3

[0085] The first step is to prepare the inner rubber layer

[0086] 1a. Extrude the original inner rubber layer

[0087] Weigh silicone rubber SR: 100 kg, fumed silica: 45 kg, vulcanizing agent bis-25DBPMH: 0.6 kg, ferric oxide: 3 kg, coloring agent: 3 kg, environmentally friendly and odorless adhesive AS-88: 6 kg, 6 kg of inorganic flame retardant zinc borate for mixing, then select a soft core tire mandrel, extrude the original inner rubber layer through a silicone rubber extruder, and control the temperature of the machine head at 30 °C;

[0088] 1b. Frozen molding

[0089] The temperature in the freezing chamber of the freezing equipment is controlled at -40°C, and then the extruded original inner rubber layer is input into the pipe sleeve located in the cooling chamber for 16 minutes of freezing to obtain the formed inner rubber layer;

[0090] The second step is to wind the reinforcement layer

[0091] Weaving and winding methods are adopted on the outside of the free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com