Metal/polymer composite powder core wire material, metal/polymer composite coating and preparation method thereof

A composite coating, polymer material technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of low mechanical properties of polymer layer, loss of barrier effect, failure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

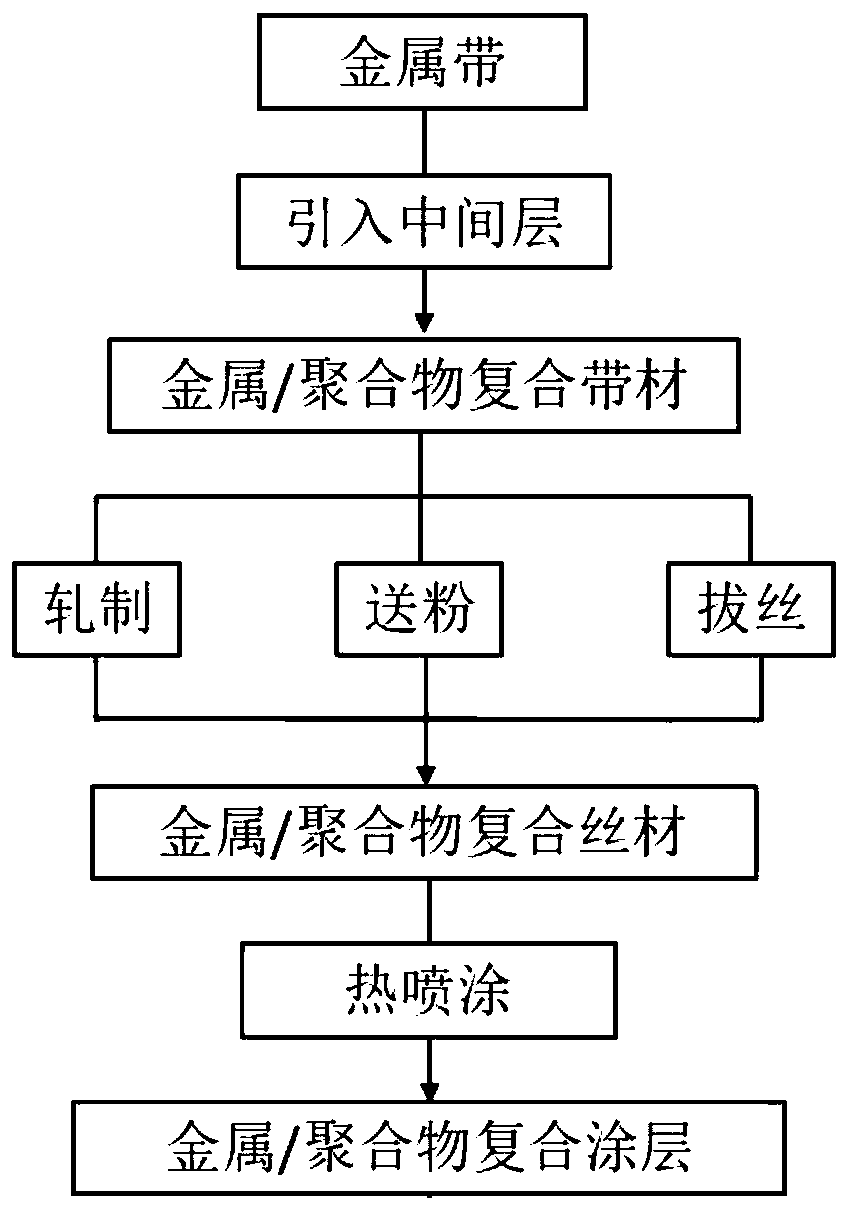

[0046] Such as figure 1 Shown, the preparation method of metal / polymer composite coating provided by the invention comprises the steps:

[0047] (1) prepare metal / polymer composite strip;

[0048] (2) prepare metal / polymer composite powder core wire material;

[0049] (3) Carry out surface degreasing and roughening treatment to the substrate;

[0050] (4) Using the metal / polymer composite powder core wire material prepared in step (2) as a spray coating material, a metal / polymer composite coating is prepared on the surface of the substrate treated in step (3) by thermal spraying.

Embodiment 1

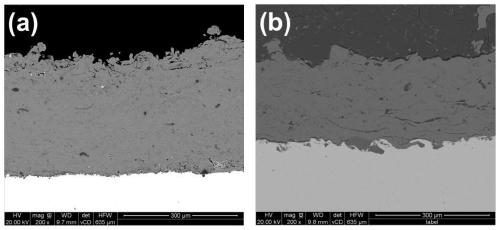

[0052] In this embodiment, the thickness of the substrate is a Q235 steel sheet of 2 mm, and the thickness of the Al / PE composite coating on the surface of the substrate is 500 μm. The specific preparation method is as follows:

[0053] 1. First, flame spray a layer of PE with a thickness of 10 μm on the 5052 aluminum alloy with a width of 7 mm and a thickness of 0.4 mm. The parameters of the flame spraying are: the supporting gas is O 2 , the pressure is 0.55MPa; the gas is acetylene, the pressure is 0.075MPa; the auxiliary gas is compressed air, the pressure is 0.8MPa, the powder feeding rate is 60g / min, the spraying distance is 250mm, the flame spray gun moving speed is 200mm / s, the number of spraying times 1 pass to obtain the Al / PE composite strip;

[0054] 2. Send the Al / PE composite strip into the roller, roll it into a groove shape, then send the PE powder into the groove, set the filling rate to 41%, close the metal strip through the roller, roll it into a circle, and...

Embodiment 2

[0061] In the present embodiment, the thickness of the matrix is 45 steel sheets of 2mm, and the stainless steel on the surface of the matrix

[0062] The thickness of the / PMMA composite coating is 500 μm, and the specific preparation method is as follows:

[0063] 1, be that width is 7mm, the thickness is the PMMA solution (20%) of 10 μ m that the stainless steel band of 0.4 mm is brushed one deck thickness, obtains stainless steel / PMMA composite strip;

[0064] 2. Feed the stainless steel / PMMA composite strip into the roll, roll it into a groove shape, then feed the PMMA powder into the groove, set the filling rate to 41%, close the metal strip through the roll, roll it into a circle, and then sequentially The diameter is gradually reduced to 1.97mm through the wire drawing dies of 2.65mm, 2.45mm, 2.20mm and 1.97mm, and the stainless steel / PMMA composite powder core wire is obtained;

[0065] 3. Sandblast the substrate with white corundum;

[0066] 4. The arc spraying p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com