A kind of high-strength and high-plastic biodegradable zn-mn-li series zinc alloy and its application

A biodegradable, zinc alloy technology, used in tissue regeneration, medical science, surgery, etc., can solve the problem of not providing zinc alloy yield strength, and achieve the effects of good cell compatibility, easy processing and excellent comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

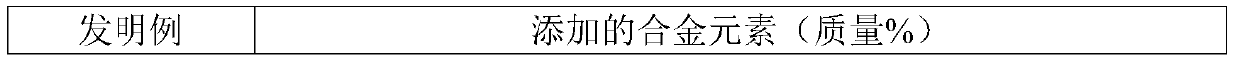

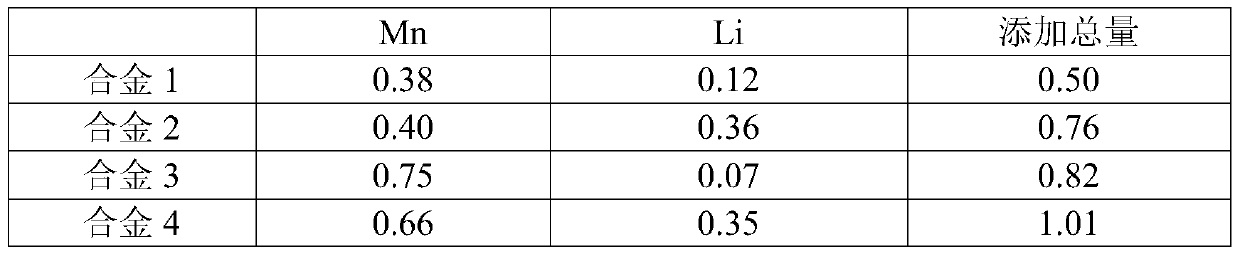

[0051] Composition, preparation and performance testing of high strength and high plasticity Zn-Mn-Li ternary zinc alloy.

[0052] The chemical compositions of the four inventive examples of the zinc alloy are shown in Table 1-1, and the balance is Zn. The preparation process of the zinc alloy is: vacuum induction smelting→homogenizing heat treatment→hot extrusion. The vacuum induction smelting uses high-purity Zn blocks and high-purity Mn and Li powders as raw materials, and the ingredients are added to the crucible according to the mass percentage, vacuumed to 5Pa and filled with argon protection, and the power is turned on, and the power is gradually increased to 5KW. After holding at 800°C for 5 minutes, pour it into a metal mold. The homogenization heat treatment is divided into two steps: first, the zinc alloy is kept at 250° C. for 2 hours, and then the furnace temperature is raised to 350° C. for 2 hours, and then air-cooled after being taken out of the furnace. The ...

Embodiment 2

[0066] Composition, preparation and performance testing of high strength and high plasticity Zn-Mn-Li-Mg quaternary alloy.

[0067] The zinc alloy contains 4 alloying elements, 3 of which are essential alloying elements: Zn, Mn and Li, and the 4th is a further added trace alloying element: Mg. The chemical compositions of the four inventive examples of the zinc alloy are shown in Table 2-1, and the balance is Zn. The preparation process of the zinc alloy is: vacuum induction smelting→homogenizing heat treatment→hot extrusion→cold rolling→intermediate heat treatment→drawing. The vacuum induction smelting uses high-purity Zn blocks and high-purity Mn, Li, Mg powders as raw materials, and the smelting is carried out according to the method provided in Example 1. Homogenizing heat treatment and hot extrusion are also carried out according to the method provided in Example 1. The cold rolling is carried out at room temperature with a deformation of 40%. The system of the interme...

Embodiment 3

[0076] Composition, preparation and performance testing of high-strength and high-plasticity Zn-Mn-Li series quinary alloys.

[0077] The zinc alloy contains 5 alloying elements, 3 of which are essential alloying elements: Zn, Mn and Li, and the 4th to 5th are further added alloying elements. The chemical compositions of the four examples of the zinc alloy are shown in Table 3-1, and the balance is Zn. The preparation process of the zinc alloy is: vacuum induction smelting→homogenizing heat treatment→hot extrusion. The vacuum induction smelting uses high-purity Zn block and high-purity Mn, Li, Mg, Cu, Ag powder as raw materials, and the preparation method is carried out according to the method provided in Example 1.

[0078] Samples were cut from the extruded rods of the zinc alloy to be tested for electrochemical corrosion, cytotoxicity and tensile mechanical properties at room temperature. The preparation and testing methods of the above samples were carried out according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com