An Immobilized Enzyme-Based Method for Rapid Evaluation of Cyclooxygenase 2 Activity Inhibition by a Marine Natural Product

A natural product, cyclooxygenase technology, applied in the field of rapid screening of COX-2 enzyme inhibitors and rapid screening of COX-2 inhibitors in natural products, can solve the cumbersome operation, repeated separation of compounds and time-consuming preparation and evaluation methods The problem of low efficiency of discovery of force and active substances, etc., to achieve the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Surface Amino Modification of SiO 2 Preparation of microspheres

[0056] (1) Activation of silica gel: Take 2.0 g of silica gel and boil it with 5% HCl for 45 minutes to remove organic matter adsorbed on the surface, then wash it with ultrapure water, and dry it at 80°C for 24 hours.

[0057] (2) Amino modified SiO 2 Preparation of microspheres (APS-Si): 0.50 g of activated SiO 2 The carrier was placed in 20 mL of toluene solution containing 5% silylating agent APS, and refluxed at 90°C for 24 hours. SiO bonded with APS 2 Wash with acetone several times to remove the unreacted silylating agent, volatilize excess acetone at room temperature, dry in an oven at 110°C for 6 hours, and store for future use.

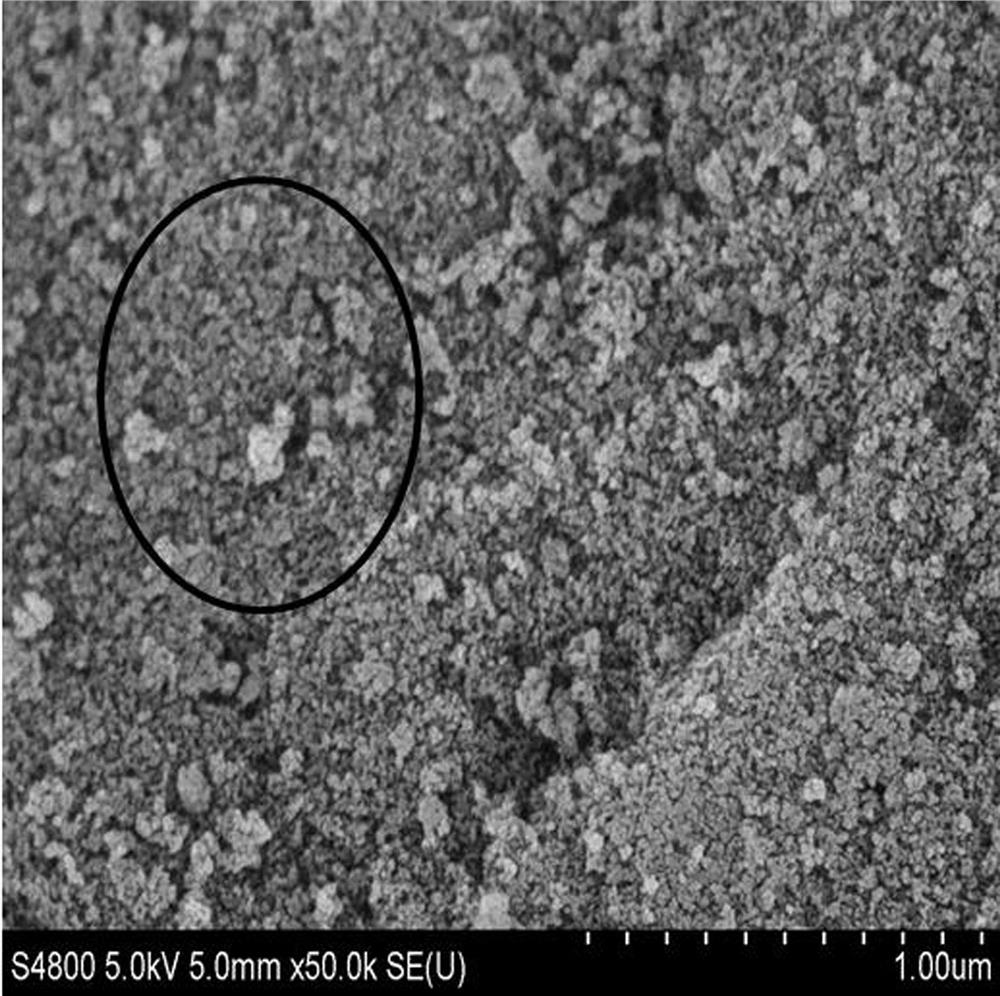

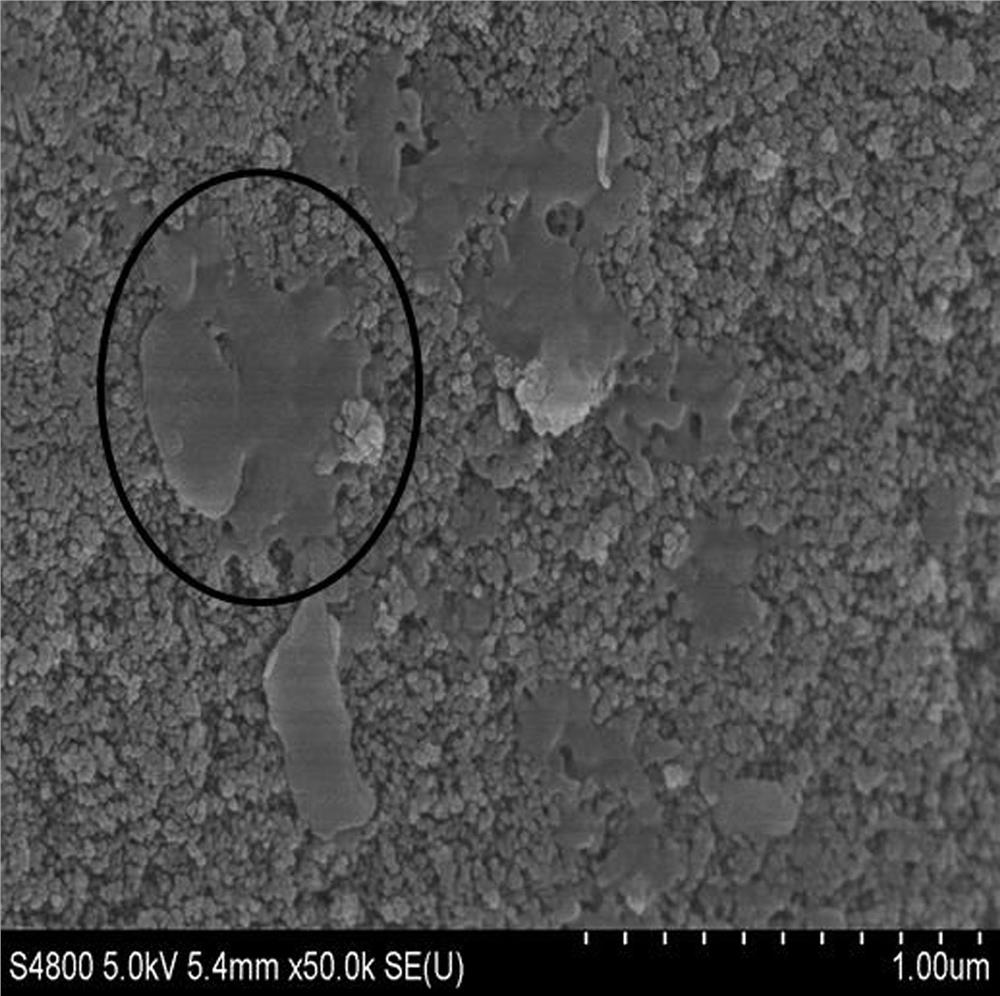

[0058] (3) Take a small amount of activated SiO 2 , APS-Si powder is adhered to the sample holder, which is then placed in an ion sputtering apparatus for gold plating. After the gold plating is completed, it is transferred to the FESEM sample cell, and ...

Embodiment 2

[0059] The preparation of the APS-Si immobilized COX-2 enzyme of embodiment 2 surface amino groups

[0060] (1) Prepare surface amino-modified APS-Si according to Example 1.

[0061] (2) Preparation of PBS: weigh 4.56gK 2 HPO 4 Dissolve in 200mL ultra-pure water as liquid A, weigh 2.72g KH 2 PO 4 Dissolve in 200mL ultrapure water to form B solution. Mix A and B at a volume ratio of 80.2:19.8 to obtain a PBS buffer solution with a concentration of 0.1mol / L and a pH of 7.4.

[0062] (3) Precisely weigh 0.050g APS-Si and place it in 2.0mL PBS buffer solution to make it fully swell, then add 10µL GA solution with a concentration of 50% (w / w), shake at a constant temperature at 28°C for 6h, and then use Wash with ultrapure water until there is no GA in the cleaning solution, and filter until dry. Add 1mL PBS buffer and 20U COX-2 solution (20µL) to the cross-linked silica gel carrier, shake and fix at 20°C for 24h, after the reaction is completed, wash with 3.5% NaCl solution, ...

Embodiment 3

[0064] Example 3 Determination of immobilized COX-2 enzyme and free enzyme activity.

[0065] (1) Preparation of levoephrine solution: Weigh a certain amount of levoephrine into a brown volumetric flask, add Tris-HCl and dissolve with a small amount of HCl, and finally add Tris-HCl to the scale to make the final concentration 40mmol / L.

[0066] Preparation of heme solution: Weigh a certain amount of heme and place it in a brown volumetric flask, add DMSO to prepare a heme solution with a concentration of 1 mmol / L, and dilute it to 100 μmol / L with Tris-HCl.

[0067] (2) Take 200 µL of immobilized COX-2 enzyme solution, add 2 µL of heme and 10 µL of levoephrine, mix well, and incubate at room temperature (20°C) for 2 min. Afterwards, 20 µL of AA was added to the buffer to make the final concentration 2 mg / L, and reacted in a metal bath at 37 °C for 30 min. After the reaction, the solution was centrifuged for 75sec (1.2×10 4 rpm), take the supernatant and let it stand at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com