A kind of preparation method of feconicumo high entropy alloy film

A high-entropy alloy and thin-film technology, which is applied in the field of new alloy thin-film materials, can solve problems such as the difficulty in realizing the industrial application of high-entropy alloy thin films, flammability of organic solvents, and harsh storage conditions, and achieve high safety and reliability, easy operation, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

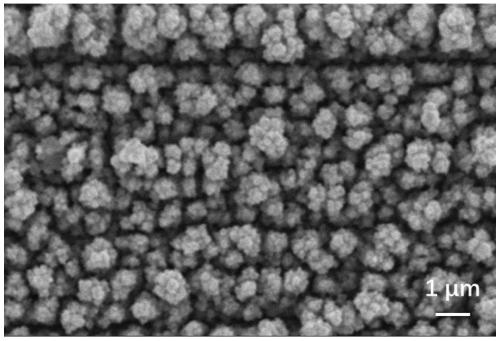

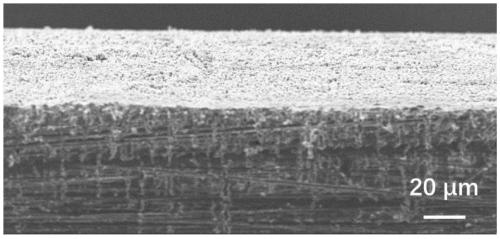

Image

Examples

Embodiment 1

[0028] The method for preparing the FeCoNiCuMo high-entropy alloy thin film of the present invention, the contents of each component in the electroplating solution used are as follows: ferrous sulfate heptahydrate 4.0g / L, cobalt chloride hexahydrate 3.0g / L, nickel chloride hexahydrate 3.0g / L, copper chloride dihydrate 1.0g / L, ammonium molybdate tetrahydrate 24.0g / L, trisodium citrate 11.0g / L, triethanolamine 2.4mL / L, glycine 0.6g / L, ethylene glycol 0.42mL / L, ascorbic acid 1.0g / L, lithium perchlorate 3.0g / L.

[0029] Concrete preparation method comprises the following steps:

[0030] Step S1, take three 150mL deionized water respectively, first dissolve 1.2mL triethanolamine in the first 150mL deionized water, then add 12g ammonium molybdate tetrahydrate and 0.5g copper chloride dihydrate, stir until dissolved, Obtain solution A;

[0031] Step S2, dissolving 0.3g of glycine, 0.21mL of ethylene glycol, 0.5g of ascorbic acid, and 1.5g of lithium perchlorate in the second port...

Embodiment 2

[0036] The method for preparing the FeCoNiCuMo high-entropy alloy thin film of the present invention, the contents of each component in the electroplating solution used are as follows: ferrous sulfate heptahydrate 4.5g / L, cobalt chloride hexahydrate 3.5g / L, nickel chloride hexahydrate 3.5g / L, copper chloride dihydrate 1.5g / L, ammonium molybdate tetrahydrate 25.0g / L, trisodium citrate 12.0g / L, triethanolamine 2.5mL / L, glycine 0.7g / L, ethylene glycol 0.44mL / L, ascorbic acid 1.1g / L, lithium perchlorate 3.5g / L.

[0037] Concrete preparation method comprises the following steps:

[0038] Step S1, take three parts of 150mL deionized water and put them in three beakers, first dissolve 1.25mL of triethanolamine in the first part of 150mL of deionized water, then add 12.5g of ammonium molybdate tetrahydrate and 0.75g of chlorine dihydrate Copper chloride was stirred until dissolved to obtain solution A;

[0039] Step S2, dissolving 0.35g of glycine, 0.22mL of ethylene glycol, 0.55g...

Embodiment 3

[0044] The method for preparing the FeCoNiCuMo high-entropy alloy film of the present invention, the contents of each component in the electroplating solution used are as follows: ferrous sulfate heptahydrate 4.2g / L, cobalt chloride hexahydrate 3.3g / L, nickel chloride hexahydrate 3.2g / L, copper chloride dihydrate 1.2g / L, ammonium molybdate tetrahydrate 24.0g / L, trisodium citrate 11.0g / L, triethanolamine 2.4mL / L, glycine 0.7g / L, ethylene glycol 0.44mL / L, ascorbic acid 1.1g / L, lithium perchlorate 3.0g / L, nano titanium dioxide 0-20g / L.

[0045] Concrete preparation method comprises the following steps:

[0046] Step S1, take three 150mL deionized water and put them in three beakers, first dissolve 1.2mL triethanolamine in the first 150mL deionized water, then add 12g ammonium molybdate tetrahydrate and 0.6g dihydrate chloride Copper, stirred until dissolved to obtain solution A;

[0047] Step S2, dissolving 0.35g of glycine, 0.22mL of ethylene glycol, 0.55g of ascorbic acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com