Oily water treatment equipment

A kind of water treatment equipment and oil-water separation technology, which is applied in the field of water treatment, can solve the problems of ineffective treatment of emulsified oil, ineffective treatment of emulsified oil, weak impact load resistance, etc., to achieve treatment residence time, reduce equipment operation risk, Improve the effect of shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

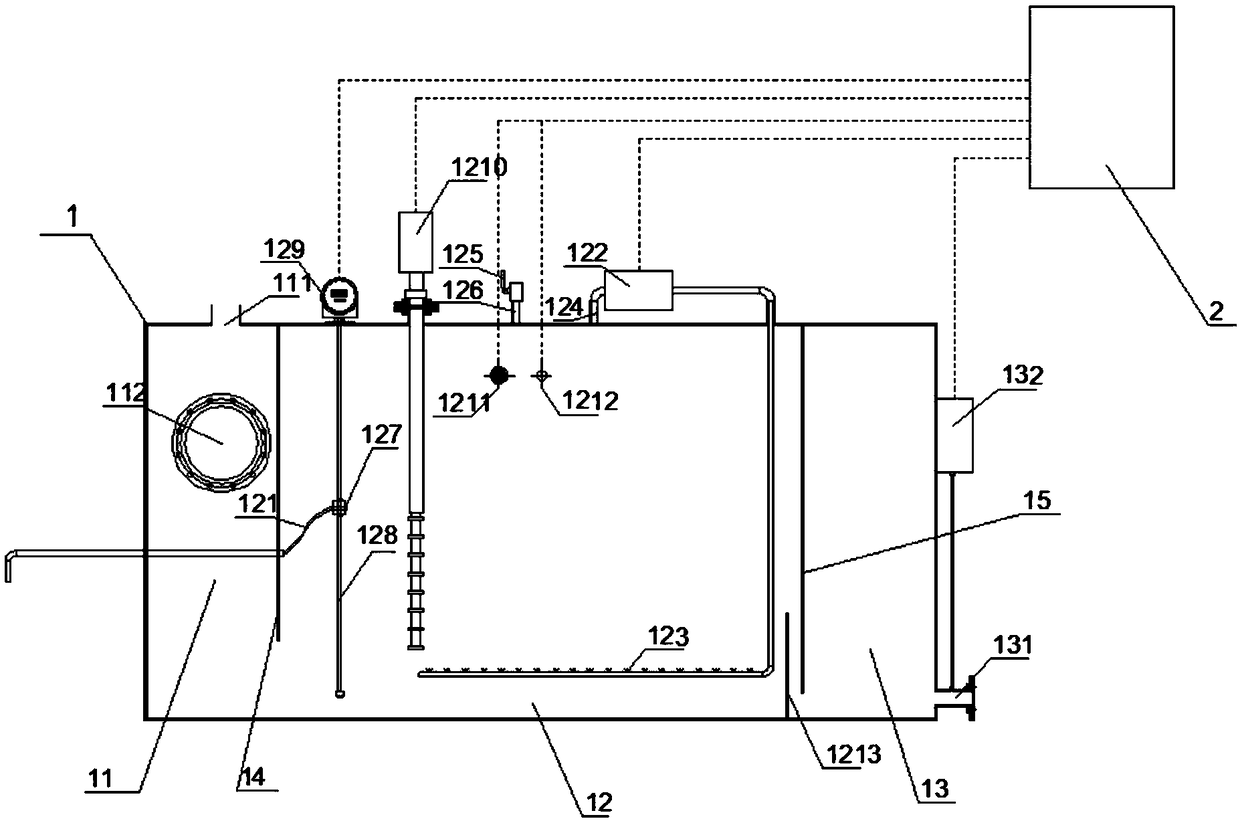

[0043] This embodiment provides an oil-containing water treatment equipment, which can be used for the oil-water separation of catering wastewater after slag removal treatment; it can also be directly used for the oil-water treatment of industrial wastewater containing no or less solids.

[0044] Such as figure 1 As shown, the oily sewage treatment equipment includes an oil-water separation tank 1, which includes a diversion tank 11, an enhanced separation tank 12, and a drainage tank 13, which are independent of each other and communicate with the lower part in sequence; the upper part of the diversion tank 11 is provided with an inlet The water outlet 111; the enhanced separation bin 12 is provided with an oil discharge pipe 121; the lower part of the drainage bin 13 is provided with a water outlet pipe 131.

[0045] When working, the oily sewage enters the diversion tank 11 from the water inlet 111, flows from top to bottom under the diversion effect of the diversion tank 11 and ...

Embodiment 2

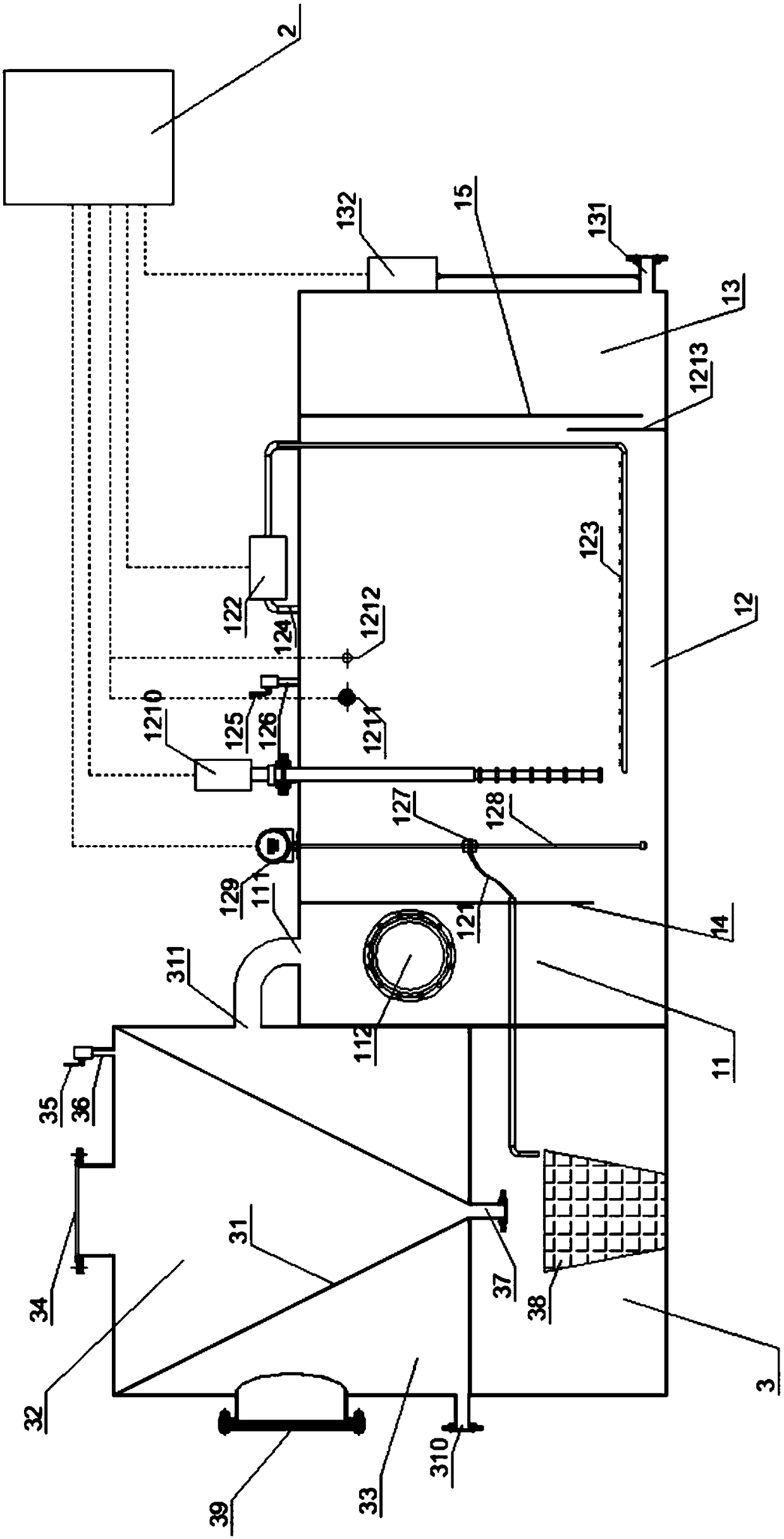

[0061] The oily sewage treatment equipment of this embodiment, on the basis of embodiment 1, has multiple pre-treatment steps in the process, and adds a solid-liquid separation bin to the physical structure, which is mainly used to treat wastewater containing solids. Such as slag removal and oil separation treatment of catering wastewater.

[0062] Specific as figure 2 As shown, the water outlet 311 of the solid-liquid separation bin 3 is in communication with the water inlet 111 of the diversion bin 11, and the water outlet 311 of the solid-liquid separation bin 3 is higher than the water inlet 111 of the diversion bin 11. Through the above arrangement, firstly, the moisture in the separated solid impurities can be reduced by gravity flow; secondly, the solid impurities can be discharged by gravity flow.

[0063] Specifically, the solid-liquid separation bin 3 includes an upper and lower part, the upper part is divided into an inner and an outer chamber by a solid-liquid separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com