Method for making welding pad

A manufacturing process and conductive layer technology, applied in the field of making self-aligned pads, which can solve problems such as short circuits and out-diffusion of copper atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

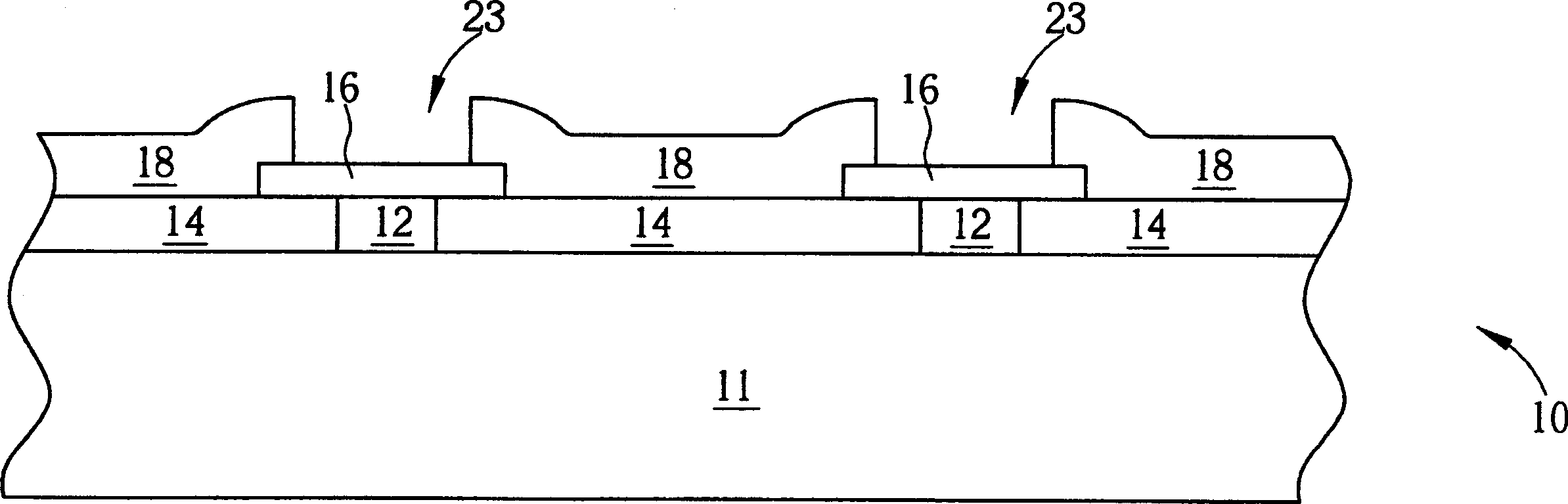

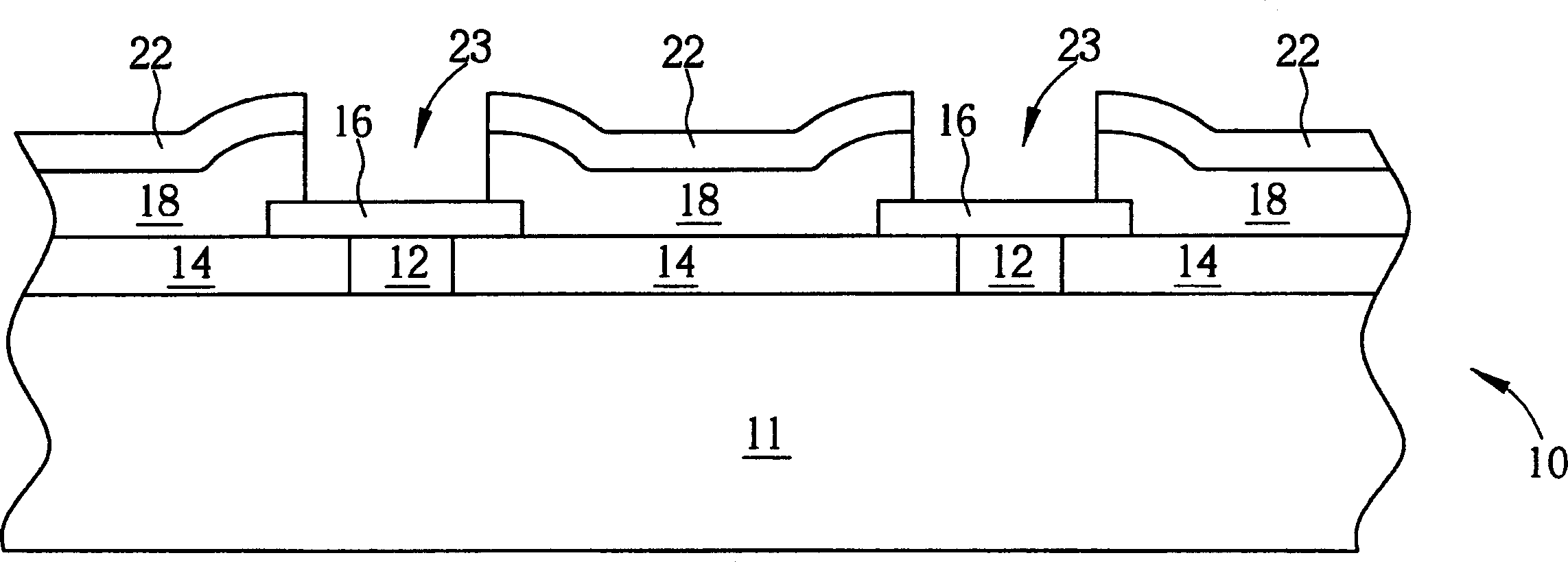

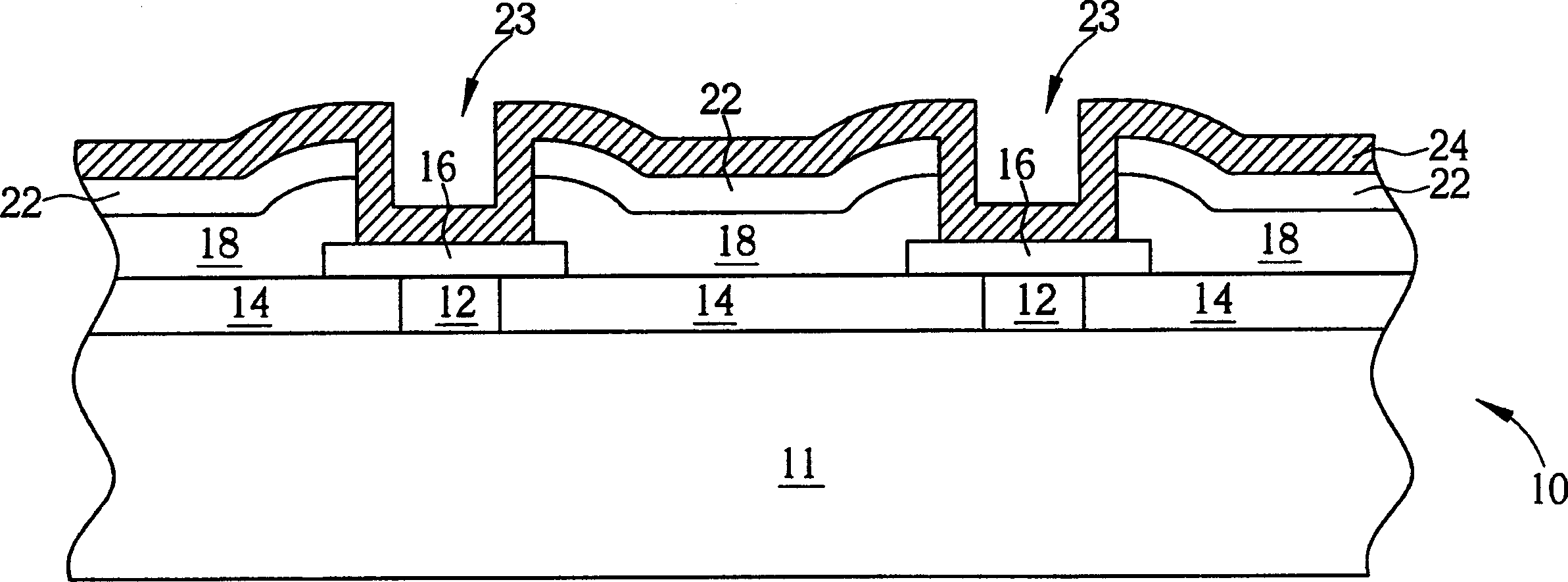

[0015] see Figure 5 to Figure 8 , Figure 5 to Figure 8 It is a schematic diagram of a method for fabricating a self-align bonding pad 109 on a semiconductor wafer according to the first embodiment of the present invention. Such as Figure 5As shown, the present invention first forms at least one conductive object 102 on the silicon substrate 101 of a semiconductor wafer 100, and the conductive object 102 may be a conductive plug, a wire (metal line), a metal interconnection ( metal interconnection) or a pair of damascene structure (dual damascence structure) conductor. Each conductive object 102 is disposed in a first dielectric layer 104 to be electrically isolated effectively, and the material constituting the conductive object 102 includes tungsten (tungsten, W), copper (copper), aluminum (aluminum), aluminum copper alloy (aluminum-copper-alloy), or other conductive materials.

[0016] and Figure 5 A conductive plug is used for illustration. First, at least one meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com