Method for preparing seaweed fermentation solution by virtue of probiotics fermentation and application of seaweed fermentation solution in cosmetics

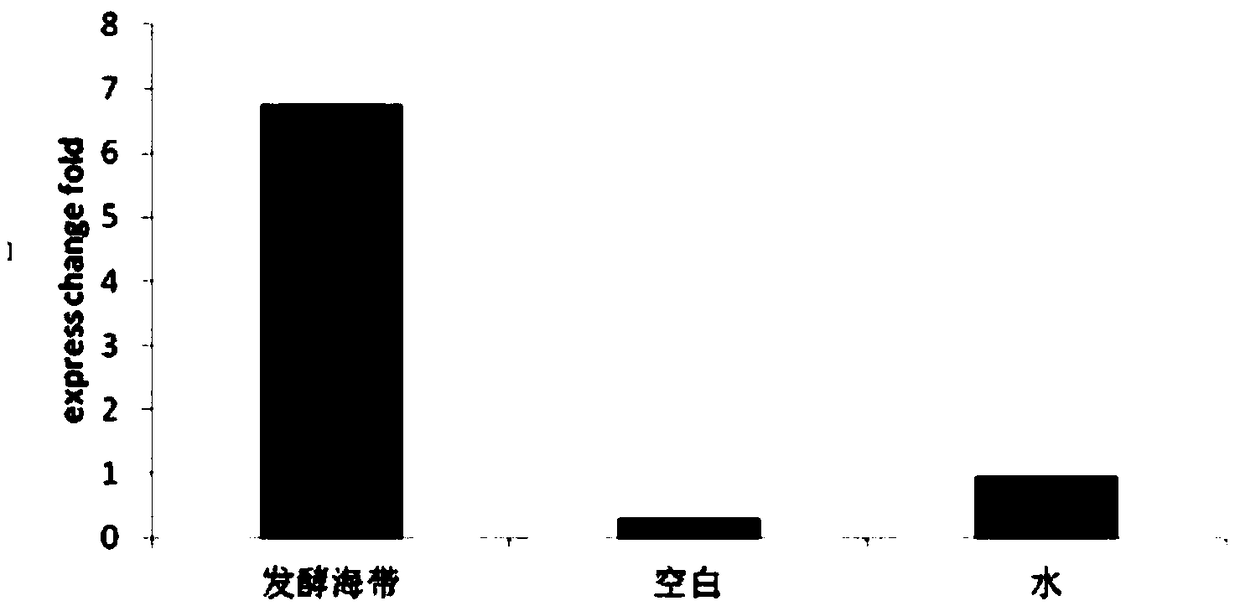

A technology of fermented liquid and probiotics, which is applied to the preparation of seaweed fermented liquid by probiotics fermentation and the application field of cosmetics, which can solve the problems of environmental pollution damage, low added value of products, and low technical content, so as to reduce pollution and promote collagen production. Protein synthesis ability, effect of increasing the type and content of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Soak the dried kelp in pure water, take 1 part of kelp and 15 parts of water; after fully soaking the dried kelp, rinse it repeatedly with pure water to wash off the sediment and salt on the surface of the kelp;

[0043] 2) The clean kelp is dried at low temperature, and the particle size of the dried kelp ultrafine powder is less than 50 μm;

[0044] 3) Activating the bacterial strains used for fermentation, wherein the bacterial strains used for fermentation are Bacillus amyloliquefaciens and Bacillus licheniformis;

[0045] 4) sterilizing the kelp dried at low temperature by irradiation, and irradiating at 1000-2500 kilorads for 2 hours;

[0046] 5) The activated Bacillus amyloliquefaciens was cultured with a fermentation medium, and the medium formula was: 1L distilled water+20g glucose+15g peptone+5g sodium chloride+0.5g beef extract. Bacillus was cultured until the number of viable cells reached 10 9 After cfu / mL, add the ultrafinely pulverized and sterilized...

Embodiment 2

[0056] 1) Soak the dried kelp in pure water, take 1 part of kelp and 10 parts of water; after fully soaking the dried kelp, rinse it repeatedly with pure water to wash off the sediment and salt on the surface of the kelp;

[0057] 2) The clean kelp is dried at low temperature, and the particle size of the dried kelp ultrafine powder is less than 70um;

[0058] 3) Activating the bacterial strains used for fermentation, wherein the bacterial strains used for fermentation are Bacillus natto; Rhodotorula viscose, Pichia powder; Lactobacillus gasseri, Bifidobacterium;

[0059] 4) sterilizing the kelp dried at low temperature by irradiation, and irradiating at 1000-2500 kilorads for 2 hours;

[0060] 5) Cultivate the activated Bacillus natto with a fermentation medium, and the medium formula is: 1L distilled water+20g glucose+15g peptone+5g sodium chloride+0.5g beef extract. Bacillus natto was cultured until the number of viable cells reached 10 9 After cfu / mL, add the ultrafinely...

Embodiment 3

[0069] 1) Soak the dried kelp in pure water, take 1 part of kelp and 17 parts of water; after fully soaking the dried kelp, rinse it repeatedly with pure water to wash off the sediment and salt on the surface of the kelp;

[0070] 2) The clean kelp is dried at low temperature, and the particle size of the dried kelp ultrafine powder is less than 100um;

[0071] 3) Activating the bacterial strain used for fermentation, wherein the bacterial strain used for fermentation is Bacillus amyloliquefaciens; Candida utilis; Streptococcus thermophilus, Lactobacillus casei;

[0072] 4) sterilizing the kelp dried at low temperature by irradiation, and irradiating at 1000-2500 kilorads for 2 hours;

[0073] 5) The activated Bacillus amyloliquefaciens was cultured with a fermentation medium, and the medium formula was: 1L distilled water+20g glucose+15g peptone+5g sodium chloride+0.5g beef extract. Bacillus amyloliquefaciens was cultured until the number of viable cells reached 10 9 After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com