Method for measuring lithium element in WE43A alloy

An alloy and element technology, applied in the field of determination of lithium element in WE43A alloy, can solve problems such as unsuitable determination of lithium element, achieve the effect of overcoming matrix background interference, reducing detection limit, and increasing sheath gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

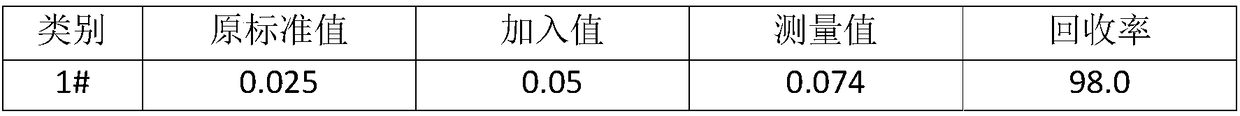

Examples

Embodiment 1

[0050]This method of determining lithium in WE43A alloy uses HJY ULTIMA IIC inductively coupled plasma emission spectrometer. The working conditions of the instrument are as follows: high frequency frequency: 40.68MHz; incident power: 1.0kW; reflected power: <10W; incident slit : 20μm; exit slit: 15μm; argon gas flow: cooling gas flow: 15L / min; sheath gas flow: 0.5L / min;

[0051] The reagents used in the method for determining the ruthenium content in superalloys by this microwave digestion method are as follows:

[0052] Hydrochloric acid, with a density of 1.19g / mL, superior grade or above;

[0053] Nitric acid, with a density of 1.42g / mL, superior grade or above;

[0054] Hydrofluoric acid, with a density of 1.15g / mL, superior grade or above;

[0055] Zinc I, manganese I, silicon I, iron I, copper I, nickel I and other single element standard solutions, the mass-volume concentration is 1.00mg / mL, purchased;

[0056] Zinc II, manganese II, silicon II, iron II, copper II, ...

Embodiment 2

[0100] This method of determining lithium in WE43A alloy uses HJY ULTIMA IIC inductively coupled plasma emission spectrometer. The working conditions of the instrument are as follows: high frequency frequency: 40.68MHz; incident power: 1.0kW; reflected power: <10W; incident slit : 10μm; exit slit: 15μm; argon gas flow: cooling gas flow: 15L / min; sheath gas flow: 1.0L / min;

[0101] The reagents used in the method for determining the ruthenium content in superalloys by this microwave digestion method are as follows:

[0102] Hydrochloric acid, with a density of 1.19g / mL, superior grade or above;

[0103] Nitric acid, with a density of 1.42g / mL, superior grade or above;

[0104] Hydrofluoric acid, with a density of 1.15g / mL, superior grade or above;

[0105] Zinc I, manganese I, silicon I, iron I, copper I, nickel I and other single element standard solutions, the mass-volume concentration is 1.00mg / mL, purchased;

[0106] Zinc II, manganese II, silicon II, iron II, copper II, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com