Surface hardness reinforced coating and preparation method thereof

A surface hardness and coating technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of complex process, complicated process, long time consumption, etc., and achieve the effect of less impurity pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Use alcohol and acetone to ultrasonically clean the metal titanium for 3 times, and let it dry naturally;

[0025] 2. Pass metal titanium into the plasma enhanced chemical vapor deposition equipment, and use a mechanical pump to vacuum below 1x10 -1 Pa;

[0026] 3. Introduce 400sccm argon gas, and raise the temperature to 900°C at a rate of 10°C / min;

[0027] 4. Inject 30sccm methane gas, turn off the argon gas, turn on the radio frequency source, set the radio frequency power to 300W, and grow for 0.5h;

[0028] 5. Turn off the radio frequency source, feed 400 sccm argon gas, stop feeding methane gas, cool down to room temperature naturally, and obtain titanium carbide / graphite enhanced coating.

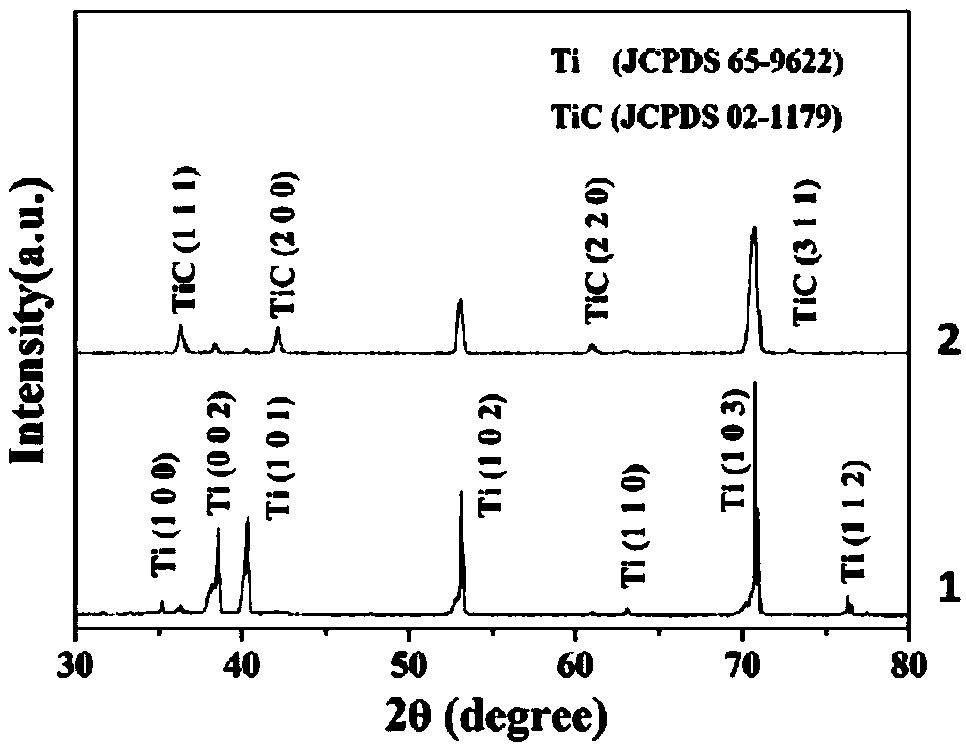

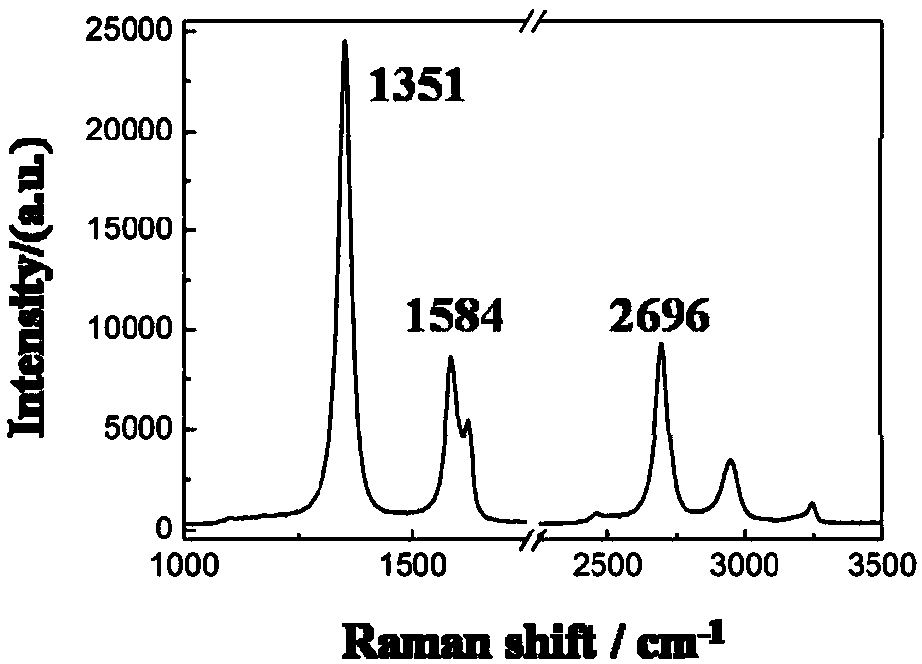

[0029] figure 1 Middle curve 2 is the XRD diffraction curve of the composite coating, and the characteristic peak of TiC is marked in the curve, and curve 1 is the X-ray diffraction curve of the comparison sample without growing composite coating; figure 2 is the Rama...

Embodiment 2

[0031] 1. Use alcohol and acetone to ultrasonically clean the metal titanium for 3 times, and let it dry naturally;

[0032] 2. Pass the titanium alloy into the plasma-enhanced chemical vapor deposition equipment, and use a mechanical pump to evacuate to a vacuum degree lower than 1x10 -1 Pa;

[0033] 3. Introduce 200sccm argon gas, and raise the temperature to 500°C at a rate of 3°C / min;

[0034] 4. Inject 10 sccm methane gas, turn off the argon gas, turn on the radio frequency source, set the radio frequency power to 100W, and grow for 2 hours;

[0035] 5. Turn off the radio frequency source, feed 200 sccm argon gas, stop feeding methane gas, cool down to room temperature naturally, and obtain titanium carbide / graphite enhanced coating.

[0036] The thickness of the titanium carbide layer is 3 μm, and the thickness of the graphite layer is 100 nm. The hardness measured under a load of 10g is 605, and the hardness of the ungrown coating sample is 204. It can be seen that t...

Embodiment 3

[0038] 1. Use alcohol and acetone to ultrasonically clean the metal titanium for 3 times, and let it dry naturally;

[0039] 2. Pass metal titanium into the plasma enhanced chemical vapor deposition equipment, and use a mechanical pump to vacuum below 1x10 -1 Pa;

[0040] 3. Introduce 400sccm argon gas, and raise the temperature to 700°C at a rate of 5°C / min;

[0041] 4. Inject 40sccm methane gas, turn off the argon gas, turn on the radio frequency source, set the radio frequency power to 200W, and grow for 1.5h;

[0042] 5. Turn off the radio frequency source, feed 400 sccm argon gas, stop feeding methane gas, cool down to room temperature naturally, and obtain titanium carbide / graphite enhanced coating.

[0043] The thickness of the titanium carbide layer is 4 μm, and the thickness of the graphite layer is 200 nm. The hardness measured under a load of 10g is 653, and the hardness of the ungrown coating sample is 204. It can be seen that the hardness of the workpiece surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com