Method for liquid nitrogen assisted preparation of high quality graphene, and high quality graphene prepared through method

A liquid nitrogen-assisted, graphene technology, applied in high-quality graphene and its preparation, liquid nitrogen-assisted preparation of high-quality graphene, high-quality graphene field, can solve the problems of poor graphene quality, high cost, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This example is used to illustrate the preparation of high-quality graphene assisted by liquid nitrogen.

[0082]1g of flake graphite (purchased from Sigma-Aldrich Company, 50 mesh, purity 99% by weight, the same below) was added to 50ml perchloric acid (purchased from Beijing Chemical Plant, mass concentration was 72%), stirred at room temperature for 3min ,filter.

[0083] The filtered graphite was placed in a corundum crucible, filled with argon and sealed. Put the crucible in a microwave oven (Galanz domestic microwave oven, 700W power), microwave for 3 minutes, take it out after cooling, and obtain 600ml fluffy worm-like graphite.

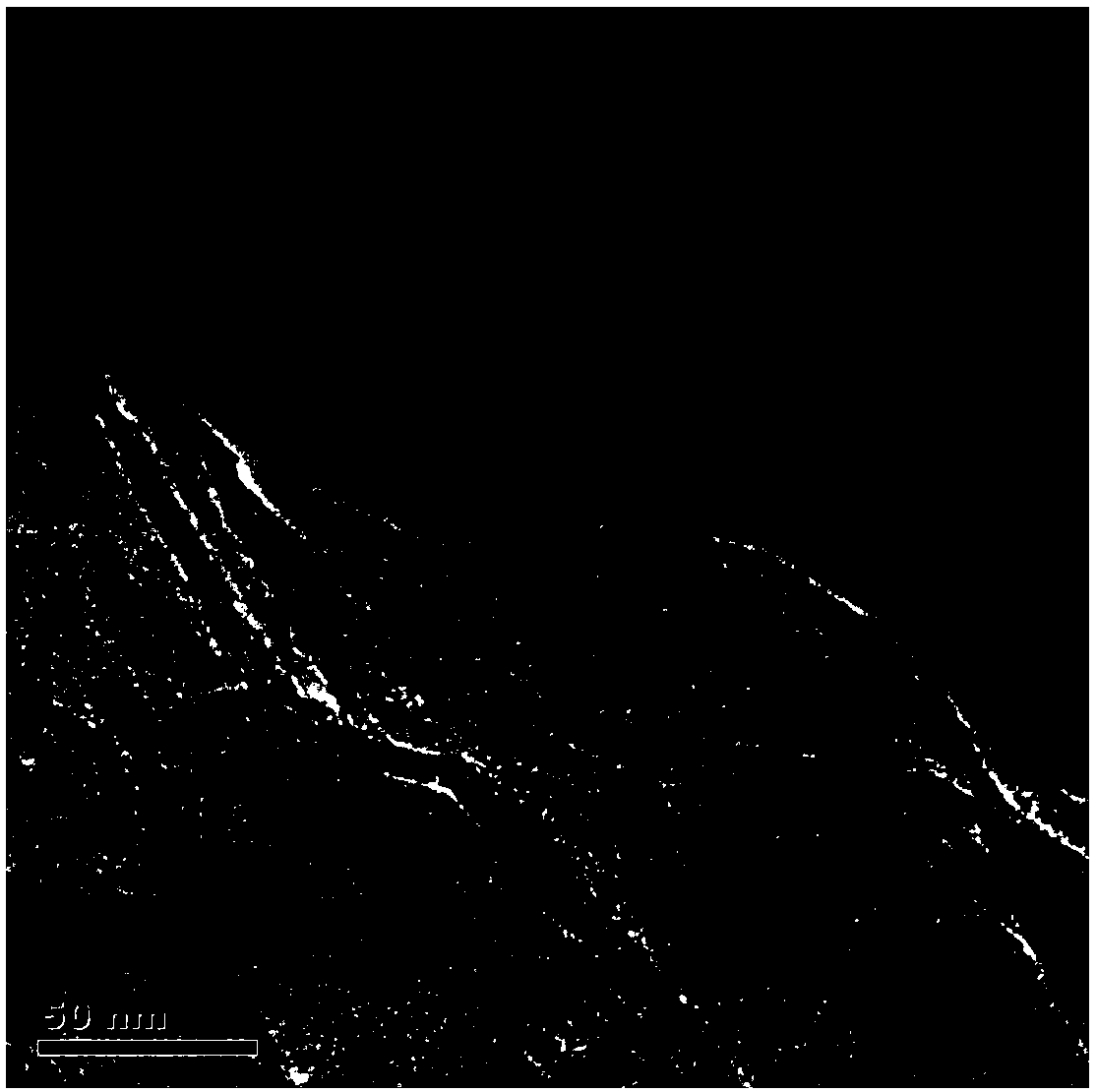

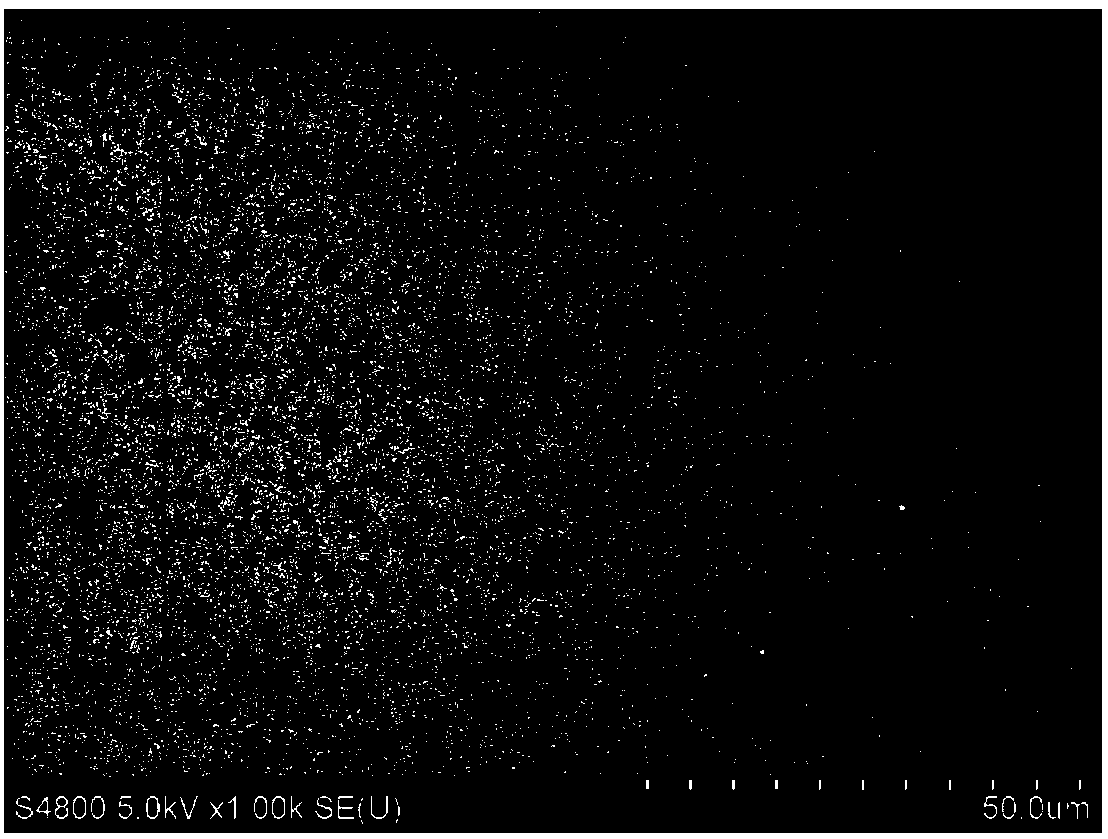

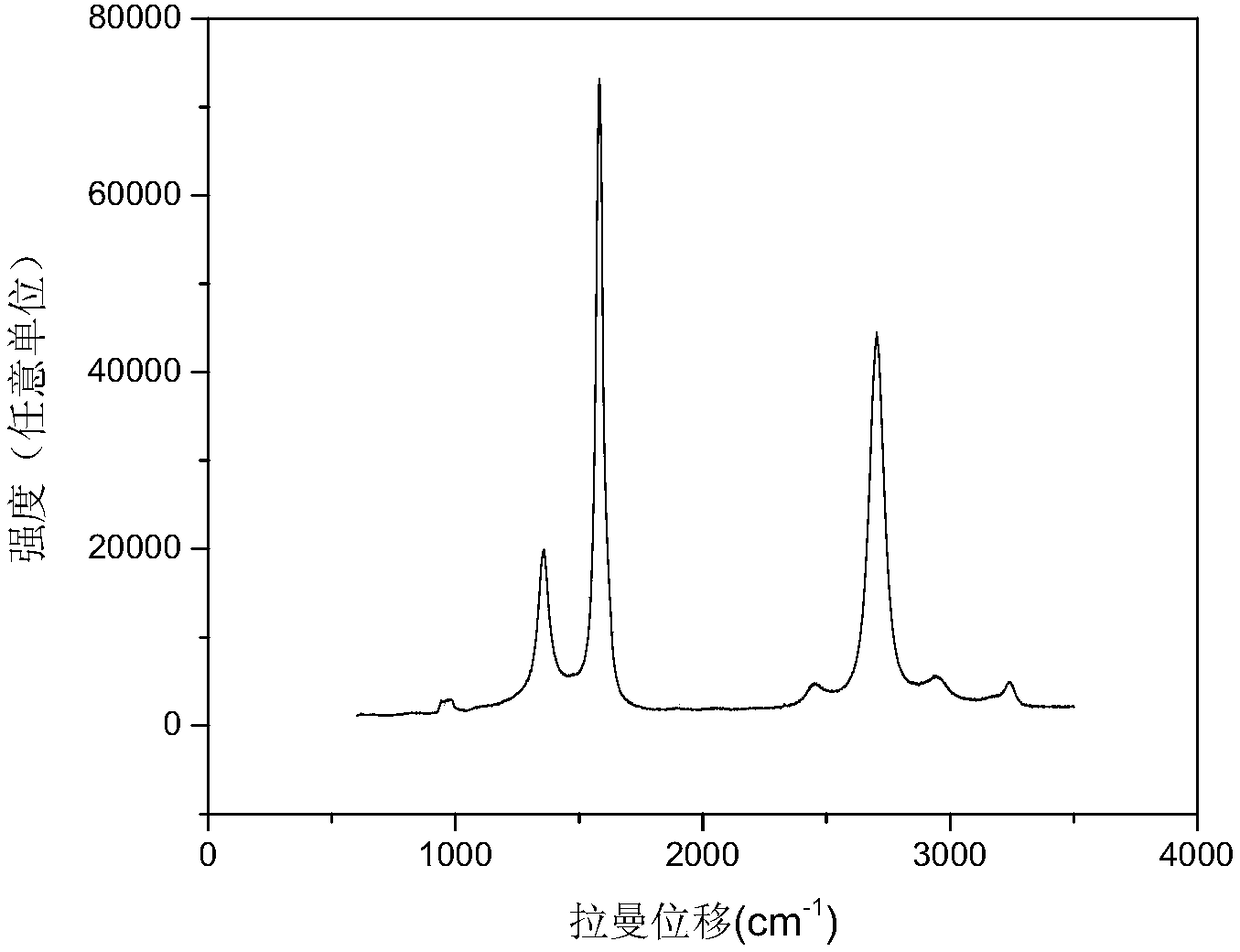

[0084] Put the worm-like graphite obtained by microwave into a 1000ml beaker, add 600ml of liquid nitrogen, and then use a high-speed mechanical stirrer to stir (the instrument was purchased from IKA, T 18 digital ULTRA-TURRAX, S 18N-19G dispersing cutter head). The rotation speed was set at 15000r / mi, the time was 20min, and liquid n...

Embodiment 2

[0091] This example is used to illustrate the preparation of high-quality graphene assisted by liquid nitrogen.

[0092] 1g flake graphite (purchased from Sigma-Aldrich Company, 50 mesh, purity 99% by weight, the same below) was added to 50ml of concentrated sulfuric acid (purchased from Beijing Chemical Plant, mass concentration was 98%), stirred at room temperature for 2 God, filter.

[0093] The filtered graphite was placed in a corundum crucible, filled with argon and sealed. Put the crucible in a microwave oven (Galanz domestic microwave oven, 700W power), microwave for 3 minutes, take it out after cooling, and obtain 320ml fluffy worm-like graphite.

[0094] Put the worm-like graphite obtained by microwave into a 1000ml beaker, add 600ml of liquid nitrogen, and then use a high-speed mechanical stirrer to stir (the instrument was purchased from IKA, T 18 digital ULTRA-TURRAX, S 18N-19G dispersing cutter head). The rotation speed was set at 15000r / min, the time was 20min...

Embodiment 3

[0097] This example is used to illustrate the preparation of high-quality graphene assisted by liquid nitrogen.

[0098] 1g of flake graphite (purchased from Sigma-Aldrich company, 50 mesh, purity 99% by weight, the same below) was added to 50ml of concentrated nitric acid and concentrated sulfuric acid mixed acid (the volume ratio of concentrated nitric acid and concentrated sulfuric acid was 3:2, and the concentrated nitric acid Purchased from Beijing Chemical Plant, the mass concentration is 98%, concentrated sulfuric acid was purchased from Beijing Chemical Plant, the mass concentration was 98%), stirred at room temperature for 2 days, and filtered.

[0099] The filtered graphite was placed in a corundum crucible, filled with nitrogen and sealed. Put the crucible in a microwave oven (Galanz domestic microwave oven, 700W power), microwave for 3 minutes, take it out after cooling, and obtain 480ml fluffy worm-like graphite.

[0100] Put the worm-like graphite obtained by mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com