Ultra-high-density boron germanotelluriteb scintillation glass and preparation method thereof

A scintillation glass, ultra-high-density technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of reduced radiant luminescence intensity, lack of practicability, inability to ensure high light yield at the same time, and achieve a simple preparation process. , The effect of good chemical stability and easy adjustment of chemical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

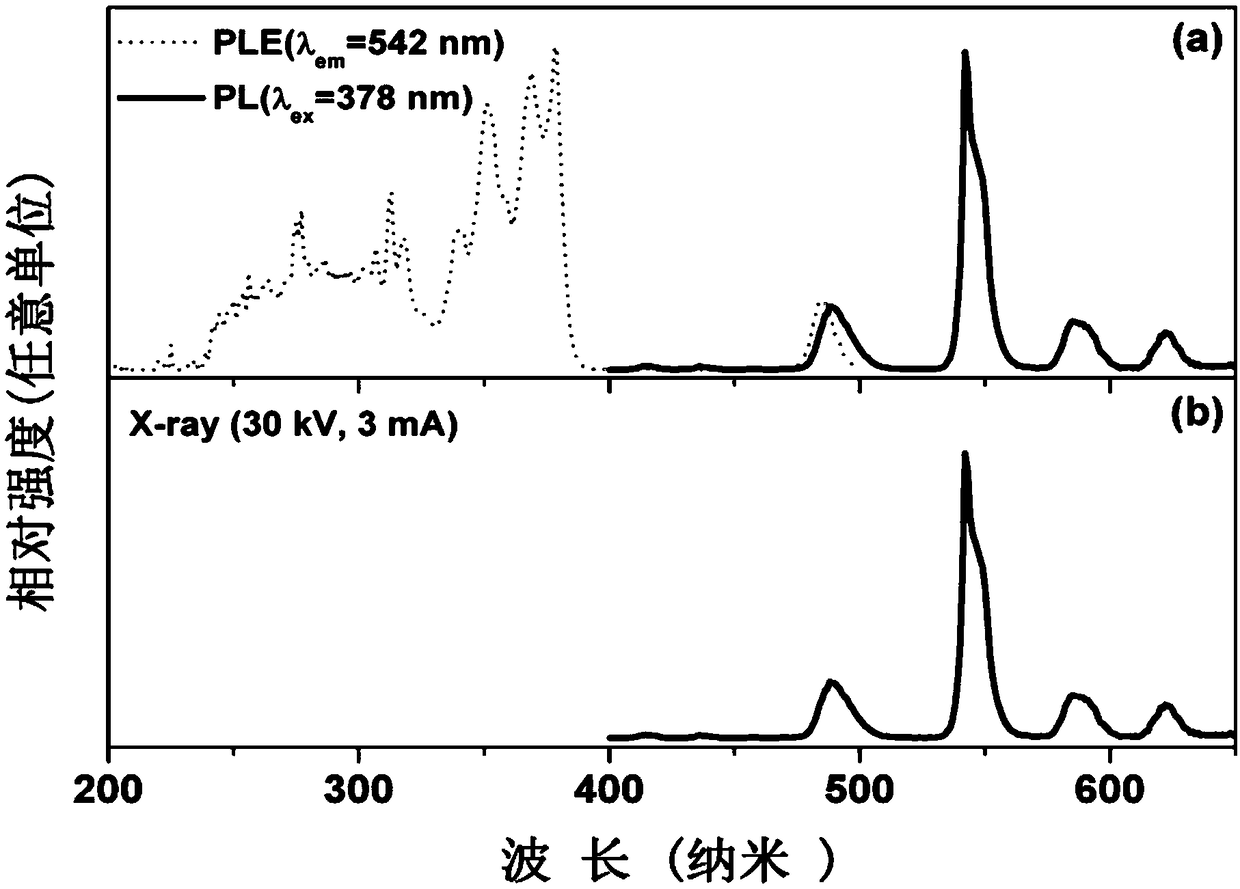

[0043] This example relates to Tb 3+ Preparation and testing of activated ultra-high density borogermanium tellurate scintillation glass.

[0044] Step 1: Accurately weigh each component according to the ultra-high-density borogermanium tellurate scintillation glass formula in Table 1, mix well and melt it in an air atmosphere at 1550°C for 90 minutes by high-temperature melting method;

[0045] Step 2: Pour the above-mentioned homogeneous melt into a preheated 400°C stainless steel mold for casting, and cool naturally to form glass; and

[0046] Step 3: Put the above glass in a muffle furnace at 600° C. for 3.5 hours and heat it for 3.5 hours for annealing treatment to obtain the scintillation glass according to Example 1.

[0047] Step 4: Cut the glass into 15×20×2.5mm 3 Specifications, ultra-high density borogermanium tellurate scintillation glass obtained after surface grinding and polishing.

[0048] Table 1. Composition of ultra-high-density borogermanium tellurate sc...

Embodiment 2

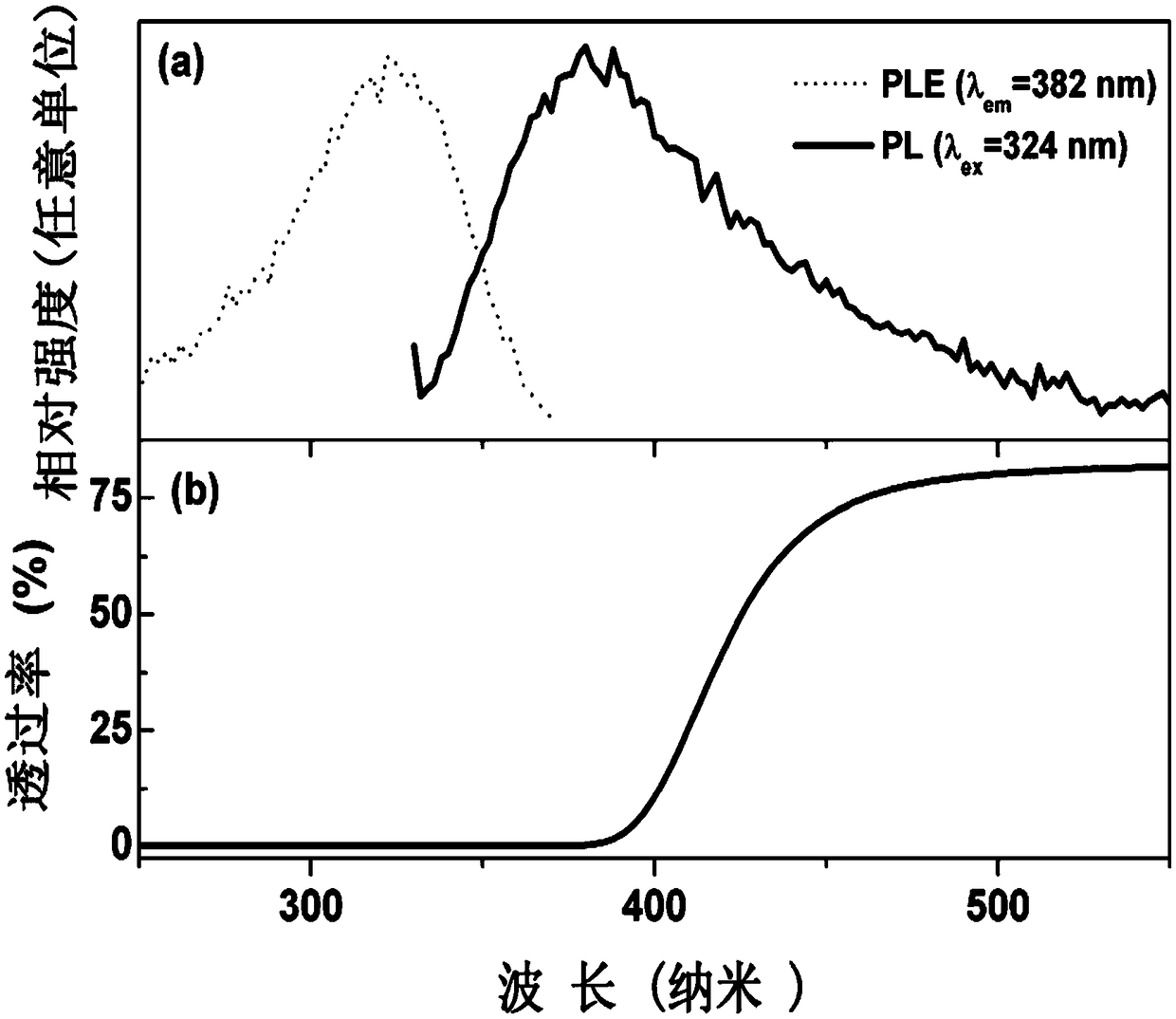

[0053] This example involves Ce 3+ Activate the ultra-high-density borogermanium tellurate scintillation glass, the specific glass composition of Example 2 is given in Table 1, and the luminescent center is Ce 3+ For ions, the melting temperature is 1535°C, the melting time is 90min, and the melting atmosphere is air.

[0054] figure 2 It is the photoluminescence spectrum and transmission spectrum of the scintillation glass of Example 2. from figure 2 (a) It can be seen that a broad peak located between 350-500nm corresponds to Ce 3+ The nanosecond optical transition of ions 5d-4f has the strongest emission peak near 382nm. from figure 2 (b) Ce 3+ The transmission spectrum of the activated ultra-high density borogermanium tellurate scintillation glass can be seen because its UV cut-off absorption edge is located at 400nm, which is higher than the Ce 3+ The ions are the strongest emitters, so they are almost completely self-absorbed under X-ray excitation without radi...

Embodiment 3

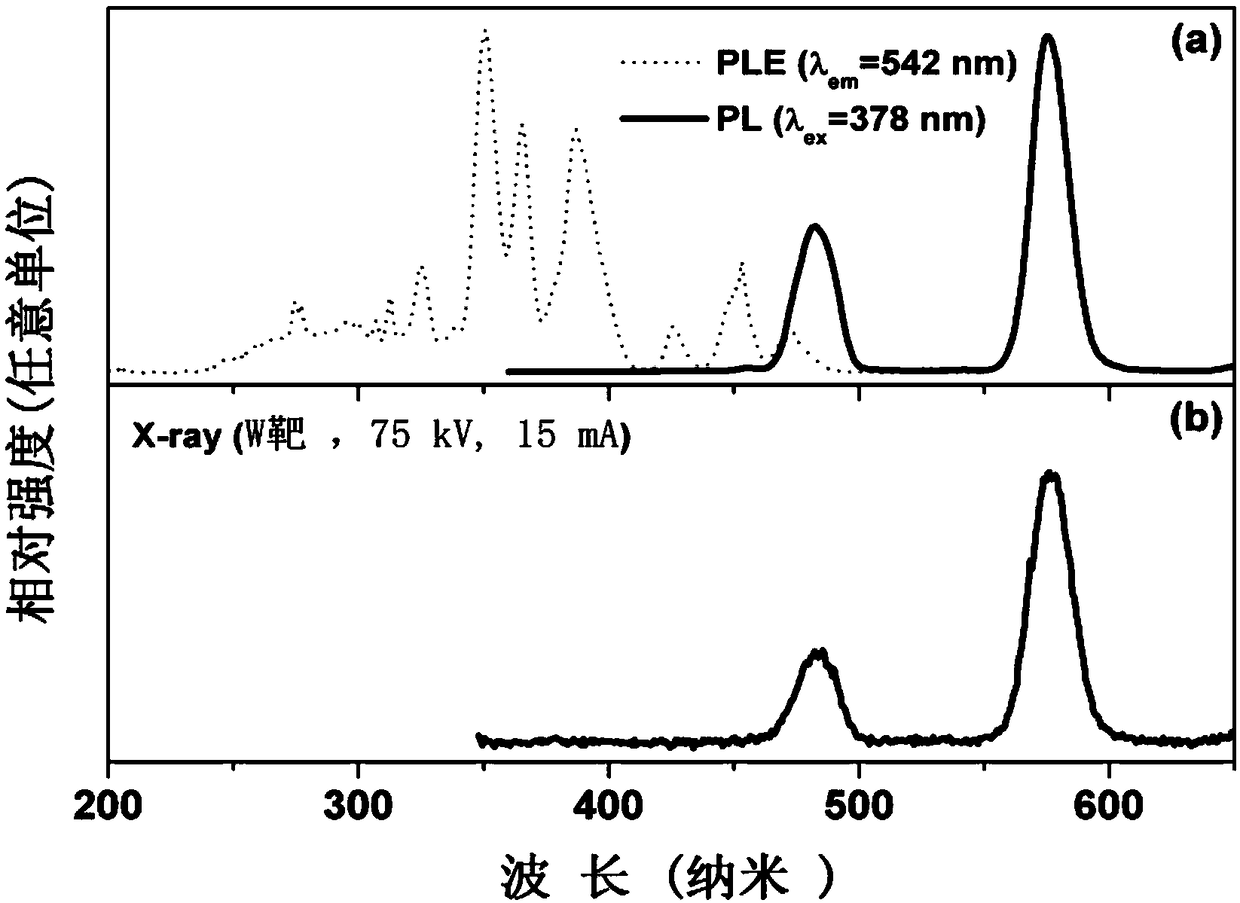

[0056] This embodiment relates to Dy 3+ Activate ultra-high-density borogermanium tellurate scintillation glass, the specific glass composition of Example 3 is given in Table 1, and the luminescent center is Dy 3+ For ions, the melting temperature is 1535°C, the melting time is 90min, and the melting atmosphere is air.

[0057] image 3 It is the photoluminescence spectrum and the X-ray excitation emission spectrum of the scintillating glass of embodiment 3, can observe and be positioned at 483nm and 577nm etc. strong emission peak, correspond to Dy 3+ Ionic 4 f 9 / 2 → 6 h J (J = 15 / 2 and 13 / 2) Optical transitions. And under X-ray (W target, 75kV, 15mA) excitation, obtain the scintillation light output of embodiment 3 scintillation glass, as image 3 As shown in (b), its characteristic emission peak is exactly the same as that of photoluminescence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com