al/al of td/drm process for semiconductor 8-inch wafer thin film process 2 o 3 Regeneration method of parts

A semiconductor and wafer technology, applied in the field of semiconductor process product regeneration, can solve the problems of mechanical damage and performance impact of semiconductor components, and achieve the effect of easy recycling, thorough cleaning and regeneration, and improving cleaning effect and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

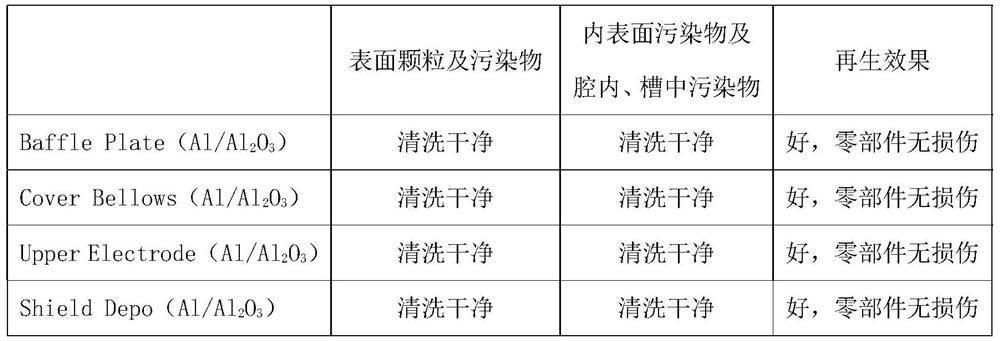

[0031] Al / Al of the TD / DRM process of the semiconductor 8-inch wafer film manufacturing process of the present invention 2 o 3 Components include Baffle Plate(Al / Al 2 o 3 ), Cover Bellows (Al / Al 2 o 3 ), Upper Electrode (Al / Al 2 o 3 ), Shield Depo (Al / Al 2 o 3 ) four parts; the present invention is based on four kinds of Al / Al 2 o 3 The structure of the parts is used to select the regeneration process, because the four Al / Al 2 o 3 All components have structures such as inner chambers and grooves. Therefore, regeneration by dry ice particle blasting alone will cause incomplete regeneration. Ultrasonic assisted supercritical CO 2 Will result in increased regeneration time and cost.

[0032] Al / Al of the TD / DRM process of the semiconductor 8-inch wafer film manufacturing process of the present invention 2 o 3 The regeneration method of parts, comprises the following steps:

[0033] (1) Al / Al of the TD / DRM process of the semiconductor 8-inch wafer film process to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com